Sign up for our weekly newsletter

Construction Canada weekly newsletters give the latest AEC industry news for those who build, design, engineer, specify, renovate or operate in the built environment.

08 80 00 Glazing

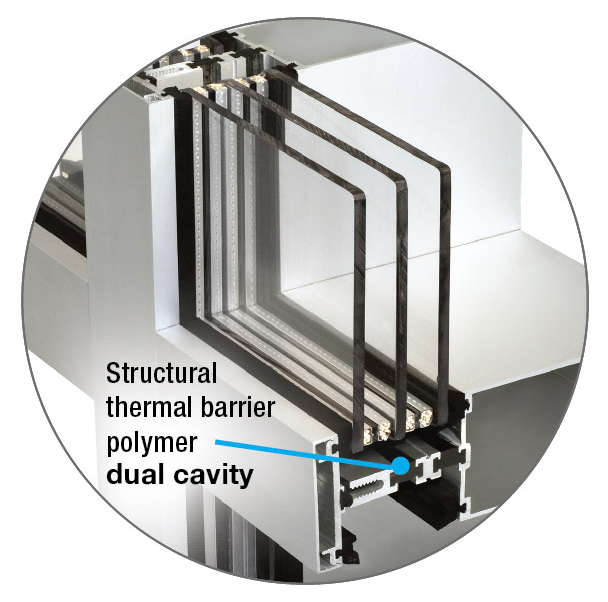

Thermal barrier technology (also known as thermal break) is a turn-key solution to optimize thermal performance for manufacturers of aluminum commercial window, door, storefront, and curtain wall materials. More widely referred to as the pour and debridge method, the structural polymer thermal barrier lowers U-factors to improve energy savings in the window assembly.

Double pour and debridge thermal barriers utilize two cavities and mechanical locks or surface conditioning prior to pouring to offer the best combination of energy efficiency and a high shear strength for aluminum fenestration products used in some of the most demanding climates and conditions.

Safety and security: Energy-efficient blast and hurricane resistant aluminum storefront and architectural window systems are available from several manufacturers using the pour and debridge thermal barriers system.

Recent breakthroughs: An emerging thermal barrier system for aluminum framing developed to cope with extreme weather conditions and acoustic performance features a high-density polyurethane foam core. The thermal and sound attenuating improvements of the foam core—when glazing infill is also high performance—contribute to energy efficiency of a building to meet stringent global energy standards, including Passive House and International Energy Conservation Code (IECC) and Sound Transmission Class (STC) ratings.