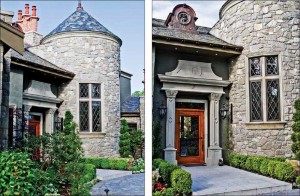

Preserving the declining art of stonemasonry

Photos courtesy New Castle Stoneworks

The use of natural stone replaces the need for concrete manufactured units. Consequently, it greatly reduces energy consumption because the amount of energy used to extract natural stone is inconsequential when compared to the amount of energy used to create and maintain artificial stone. From an environmental standpoint, cement production is one of the most energy-intensive of all industrial manufacturing processes. Roughly six per cent of total U.S. energy consumption goes into cement production, which is a remarkable amount given the fact that in dollar value, cement represents only about 0.6 per cent of the gross national product (GNP). Thus, cement production is approximately 10 times as energy-intensive as the U.S. economy in general.

Cement manufacturing also releases carbon dioxide (CO2) into the atmosphere, both directly when calcium carbonate is heated, producing lime and CO2, and also indirectly through the use of energy because its production involves CO2 emission. The cement industry is the second largest CO2-emitting industry behind power generation in the world. It also produces about five per cent of global manmade CO2 emissions, of which 50 per cent is from the chemical process, and 40 per cent from burning fuel. (There is a no actual data yet with respect to the amount of energy consumed in the extraction of natural stone. However, there is a study currently being done by the Natural Stone Council (NSC) to acquire real numbers. Visit www.naturalstonecouncil.org). Therefore, in many ways, concrete brick and block has a very high cost on the environment.

Multiple uses of natural stone

When one thinks of stone, its use in famous buildings worldwide most likely first comes to mind. However, few people perhaps realize natural stone in some form exists in the world around us and individuals encounter it hundreds of times throughout the day. (The “Stone Report” has information about natural stone use in construction, safety in the production process of natural stone, Leadership in Energy and Environmental Design (LEED) guidelines of natural stone, and more. Visit www.stonereport.com). From a geological perspective, there are hundreds of natural stones; commercially, natural stone is characterized in 10 different categories:

- granite;

- limestone;

- marble;

- onyx;

- quartzite;

- sandstone;

- serpentine;

- slate;

- soapstone; and

- travertine.

Many commercial classifications do not coincide with scientific classifications. The reason being is commercial classifications group natural stone together based on their physical attributes. Therefore, many times what is truly a ‘limestone’ scientifically is considered a ‘marble’ because of the way it appears and behaves.

Granite

Granite is the most commonly used stone in newer homes for kitchen countertops, floors, and other heavily used surfaces. Its ability to withstand heat and abrasion-resistant properties lend it to widespread use. In contrast to many synthetic materials that easily scratch, the solidity of the minerals comprising granite surpasses almost any utensils used on it, resulting in excellent scratch resistance. Therefore, the use of granite has skyrocketed in residential interior areas.

Granite has been linked by some to the potentially harmful gas, radon. However, a cause and effect relationship between granite and radon has not been established. The U.S. Environmental Protection Agency (EPA) has stated that:

Some granite used for countertops may contribute variably to indoor radon levels. At this time, however, EPA does not believe sufficient data exist to conclude that the types of granite commonly used in countertops are significantly increasing indoor radon levels.

Health Canada has released a similar statement, stating that:

High radon levels are not widespread in Canadian homes. Because of the very low risk level, Health Canada does not have specific recommendations for possible radiation hazards from granite countertops.

Marble

Marble is a metamorphic rock that is found in most of the world’s mountainous regions. It has a naturally random visual appearance and requires little maintenance, which is why it is popularly used for fireplace facings and hearths, foyers, tabletops, windowsills, walls, and countertops.

Due to its innately warm colours, it adds a sophisticated element to any area in which it is installed. Additionally, many marbles are well-suited for wet areas, which extend the versatility of this material to include tub decks and showers. It should be noted marble is vulnerable to acids and other weathering elements; therefore, exterior applications are generally limited to white marble with some exceptions.

Sandstone and quartzite

Sandstone can be any mineralogy, but the overwhelming amount of it on the market is primarily quartz-based. Its durability and performance is not as greatly influenced by the sand-sized particles as it is to agents that bind them together. Exterior cladding is a common application of sandstone, although it is typically used in thicker sections than other stones due to its inferior bending strength. It is also used in cubic sections as sills, coping, water tables, and other exterior features.

Slate and soapstone

Due to slate and soapstone’s chemical-resistant properties, the traditional use of both of these stones was in chemistry labs. Its longstanding application alone speaks volumes to the durability of both in these aggressive environments. With slate and soapstone being some of the softer materials, neither is known to be particularly high-abrasion or scratch-resistant. Nevertheless, they are both commonly used for floors and countertops, most notably in commercial spaces. Slate is highly heat-resistant and, therefore, is often used in fireplace surrounds.

Travertine and limestone

Limestone deposits exist in all continents. Despite the common reference to ‘travertine marble,’ it is actually a type of limestone. With the soft earth tones of these stones, decorators have many options when selecting complementary colours for their interior decor. Since these stones are of the softer variety when compared to other forms of natural stone, they have been a primary choice for intricately carved decorative home features and moldings as well as statuary.

Mike de Palma owns and operates the largest residential masonry contracting and stone supply company in Victoria, B.C.––New Castle Stoneworks. It has been in business since 1969. He can be reached via e-mail at info@newcastlestoneworks.com.

Hellen Diaz, BA, works in marketing communications for New Castle Stoneworks. She holds a business administration diploma and degree in professional communications from Royal Roads University (Victoria). Diaz can be reached via e-mail at hellenediaz@hotmail.com.