Plumbing with PEX

Cold expansion fittings

To use cold-expansion fittings, an expander tool is placed inside the tubing to enlarge the PEX. The tool is turned multiple times until the tubing is expanded to the manufacturer’s specifications. With the ASTM F1960 design, the expanded tubing end is allowed to retract onto the fitting to form the seal with the aid of a ring. The connection is enhanced by the memory effect of the tubing, thereby not solely relying on the crimping mechanism for its security.

The latest generation of PEX fittings—cold-expansion with PEX compression sleeve—takes this connection security up a notch and speeds the formation of the connection by actively compressing a PEX sleeve over the expanded tubing and fitting.

Fixture flow rates of PEX and copper pipe were compared in a June 2008 study conducted by the National Association of Home Builders (NAHB) for the Plastics Pipe Institute (PPI).

It concluded, “PEX and copper piping systems will deliver sufficient volumetric flow rates to the plumbing fixtures when using the same nominal size tubing. While PEX tubing has a smaller inside diameter than copper tubing, both tubing systems meet the farthest fixture demand, even with multiple fixtures flowing.”2

Over time, corrosion and other buildup can reduce the ID of copper pipe, thus reducing flow and pressure, and its effectiveness, in a commercial plumbing system.

Pipe sizing, layout options

When sizing pipe, a good practice is to look at the pressure loss tables of the manufacturer. One must not assume the PEX system should be upsized. Doing the math ensures the client is happier due to potential savings in material and energy costs.

The required load (gallons per minute [gpm]) and the resulting pipe size is determined in accordance with the requirements of the National Plumbing Code of Canada (NPC). Once the required load is determined, the pipe can be sized based on the maximum allowable velocities, according to the prevailing local codes.

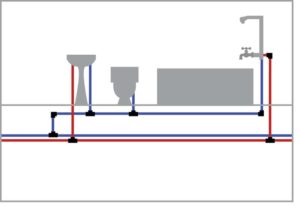

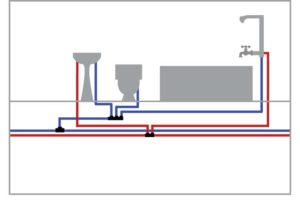

PEX has two piping layout options (tee and branch and remote multiport tee) while copper and CPVC have only one (tee and branch). A PEX tee-and-branch system uses the same layout as rigid pipe but with faster installation. Instead of fittings, installers can use bend guides and brackets to align pipes and fixtures to maximize the benefit of this method.

A remote multiport tee offers a variety of plumbing design possibilities due to the minimal number of connections required. Fewer fittings mean less leak potential and pressure loss as well as reduced installation time, which saves money for the building owner.

Codes and standards

All major model plumbing and building codes recognize PEX tubing as acceptable for water distribution piping.

Nationally accredited, third-party certification agencies, such as CSA Group and NSF International, require strenuous quality control (QC) testing, including random plant inspections and annual monitoring. Long-term hydrostatic pressure ratings as well as standardized chlorine resistance testing to ensure the piping will withstand the most aggressive drinking water conditions are also required.

Many commercial buildings require plumbing systems to be installed within return air plenums or fire-rated assemblies.

When placing PEX in a plenum, design professionals use CAN/ULC S102.2, Standard for Surface Burning Characteristics of Flooring, Floor Covering and Miscellaneous Materials and Assemblies to evaluate whether materials will help spread a fire or create smoke when burned. Individual PEX manufacturers obtain their listings and certifications for plenum applications using different installation methods such as 12.7 mm (0.5 in.) fibreglass insulation or galvanized support channels.

Underwriters Laboratories (UL) listings are required when combustible material is installed in fire-rated assemblies, such as reinforced concrete slabs, wood-framed floor/ceiling assemblies, and framed bearing and nonbearing walls.

Since potable water is disinfected using chlorine, all PEX tubing must be tested and certified by qualified third-party certification agencies to meet the requirements of CSA B137.5, Crosslinked Polyethylene (PEX) Tubing Systems for Pressure Applications, including chlorine resistance.

“PEX pipe has shown itself to be resistant to attack from chlorine and chloramines under a wide range of conditions and has performed reliably in all regions of North America,” says the ICC in its design guide.3

Plumbing professionals must also consider ultraviolet (UV) resistance when specifying PEX tubing for commercial plumbing. Most PEX has some UV resistance, but prolonged exposure to direct or indirect sunlight can damage the tubing. PEX should not be stored outdoors or used in outdoor applications unless buried in the ground or protected in some other way.

It is advisable to check with the manufacturer to find out the maximum recommended UV exposure time limit of the PEX, based on the UV resistance.4

Installation considerations

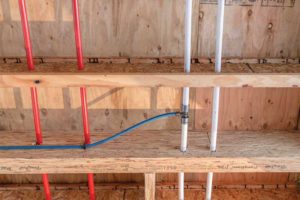

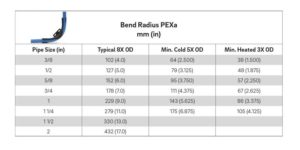

When installing PEX tubing, proper support spacing must be observed per code. PEX expands and contracts when heated and cooled, so it is important to keep this in mind when designing and specifying pathways and supports. It is recommended to choose supports that will not cut, scratch, or damage the tubing.

Standard CTS hangers can be used to support suspended sections of PEX tubing. Fixed support points will hold PEX in place and minimize the movement of the tubing during expansion or contraction, thus mitigating any damage to the pipe. Isolating suspension clamps allow the tubing to slide within the support.

To increase the spacing between support hangers, specifying engineers can choose galvanized steel support channels, into which the PEX tubing is placed. By restricting movement, these support channels minimize the expansion and contraction that occur when the tubing is heated and cooled. In general, PEX pipe expands at the rate of 25.4 mm (1 in.) for 30.5 m (100 ft) of pipe for every 12.2 C (10 F) of temperature change. Use of galvanized steel support channels control the expansion and contraction to a level that mimics copper.

Designers and specifiers must consider an approved through-penetration firestop system when PEX tubing will penetrate floors, ceilings, and walls. The most common firestop system standard for Canada is CAN/ULC S115, Tests of Fire Resistance of Building Joint Systems. It is important to ensure the firestop system meets all local code requirements before installation.

Incorporating proper controls into the PEX plumbing system is crucial, as failure to follow pressure and temperature limits may damage the tubing, resulting in leaks and possible breakdown of the system. The maximum temperature and pressure ratings of PEX plumbing systems are in accordance with CSA B137.5, Crosslinked Polyethylene (PEX) Tubing Systems for Pressure Applications and PPI TR-3, Policies and Procedures for Developing Hydrostatic Design Basis, Hydrostatic Design Stresses, Pressure Design Basis, Strength Design Basis, Minimum Required Strength Ratings and Categorized Required Strength for Thermoplastic Piping Materials or Pipe.

| RAUPEX PEXa pipe, SDR9 maximum pressures and temperatures |

| 1055 kPa at 23 C (160 psi at 73.4 F) |

| 690 kPa at 82.2 C (100 psi at 180°F) |

| 550 kPa at 93.3 C (80 psi at 200 F) |

Installation advantages

PEX tubing provides building owners reliability, durability, and cost savings, and makes plumbing installation easier and safer. CPVC plumbing systems require glue to join fittings. It is a time-consuming process, as the CPVC pipe ends must be primed, glued, and then held together while the adhesive dries.

Even more time-consuming is soldering and brazing, which is still used to install copper tubing. As this process requires a fire source, it can be a safety issue for the contractor and a liability for the building owner. Other methods to join copper are available, such as press-connect and push-connect fittings, both of which tend to be less reliable.

With PEX, installers have a flexible, easy-to-maneuver material requiring fewer fittings, which speeds up installation and reduces cost. A commercial installation time study performed by the Home Innovations Research Lab set up an experiment with two 15-year veterans of commercial plumbing in side-by-side timed installations of copper and PEX systems.

The study concluded the PEX plumbing systems installed up to 65 per cent faster than copper systems. For plumbers, PEX won over copper installations because fewer fittings are needed and measuring, cutting, and attaching fittings to the pipe takes less time.

Conclusion

A versatile material, PEX is suitable for commercial plumbing applications because it is flexible, reliable, and durable. The pliable nature of PEX allows contractors to bend and position the tubing where needed, requiring fewer fittings than rigid piping systems, thereby reducing installation time and saving building owners money.

Cold-expansion fittings help enlarge the ID of PEX tubing while providing a tight seal and virtually leak-proof connection. Further, PEX does not corrode or degrade like metal plumbing systems and, therefore, assures longevity.

Given the data and conclusions from industry sources and experience from installers, there is evidence to consider the advantages of specifying PEX in commercial plumbing projects.

Notes

1 Read “Design Guide: Residential PEX Water Supply Plumbing Systems,” Second Edition, (November 2013) from the Plastic Pipe and Fittings Association (PPFA)/International Code Council (ICC)/Plastics Pipe Institute (PPI)/Home Innovation Research Labs.

2 Consult “Fixture Flow Rate Comparison: Crosslinked Polyethylene (PEX) Piping and Copper Tubing” (June 2008) by the National Association of Home Builders (NAHB) and PPI.

3 See Note 1.

4 See Note 1.

Author

Jon Bittenbender is the director of engineering for the building solutions division of REHAU. He has been involved in the engineering of the company’s PEX-based applications, including plumbing, radiant heating and cooling, hydronic piping, turf conditioning, and snow- and ice-melting since 1999. Bittenbender holds a bachelor’s degree in mechanical engineering from Pennsylvania State University. He can be reached at jonathan.bittenbender@rehau.com.

Jon Bittenbender is the director of engineering for the building solutions division of REHAU. He has been involved in the engineering of the company’s PEX-based applications, including plumbing, radiant heating and cooling, hydronic piping, turf conditioning, and snow- and ice-melting since 1999. Bittenbender holds a bachelor’s degree in mechanical engineering from Pennsylvania State University. He can be reached at jonathan.bittenbender@rehau.com.