Plenum barriers, speech privacy, and workplace 2.0 fit-up standards

by Katie Daniel | September 21, 2017 11:27 am

[1]

[1]By Gary Madaras, PhD, Assoc. AIA

When someone enters an enclosed room, whether it is a private office or conference room, there is an expectation he or she is achieving not only visual privacy, but also sound privacy. Whether this is actually the case depends on how the room’s envelope—including the slabs, walls, doors, windows, and at times, ceiling (and what happens above)—is constructed. It is possible to have little or no visual difference between a room that has high sound privacy and one that does not. This is largely why analysis of post-occupancy survey data from office buildings shows occupants have been dissatisfied with their acoustic environment. By a wide margin, the lowest scoring metric on the surveys is sound privacy. (For more, see M. Frontczak et al’s “Quantitative Relationships Between Occupant Satisfaction and Satisfaction Aspects of Indoor Environmental Quality and Building Design,” published in January 2012 by the Center for the Built Environment’s Center for Environmental Design Research at the University of California, Berkeley.)

Workplace renewal is an ongoing priority for the Canadian government. In the “Eighteenth Annual Report to the Prime Minister on the Public Service of Canada,” the Clerk of the Privy Council stated:

A modern, healthy workplace supports greater productivity, a more engaged workforce and better results for Canadians. Deputies and managers have a responsibility to create workplaces that support the well-being, wellness and productivity of our employees.

Driven by this challenge for workplace renewal, Public Services and Procurement Canada (PSPC) has taken the lead in facilitating change across the government, through the development and implementation of the government-wide Workplace 2.0 initiative. It provides PSPC employees, client departments, agencies, and the private sector with direction and guidance on the fit-up of federal office accommodations. It applies to all office accommodation projects, and tenant services projects managed by PSPC. Workplace 2.0 is creating a modern workplace that will attract, retain, and enable public servants to work smarter, greener, and healthier to better serve Canadians. (This comes from the “Message from the Assistant Deputy Minister, John McBain,” located on page ADM-i of the Government of Canada Workplace 2.0 Fit-up Standards.)

Sound privacy in Workplace 2.0

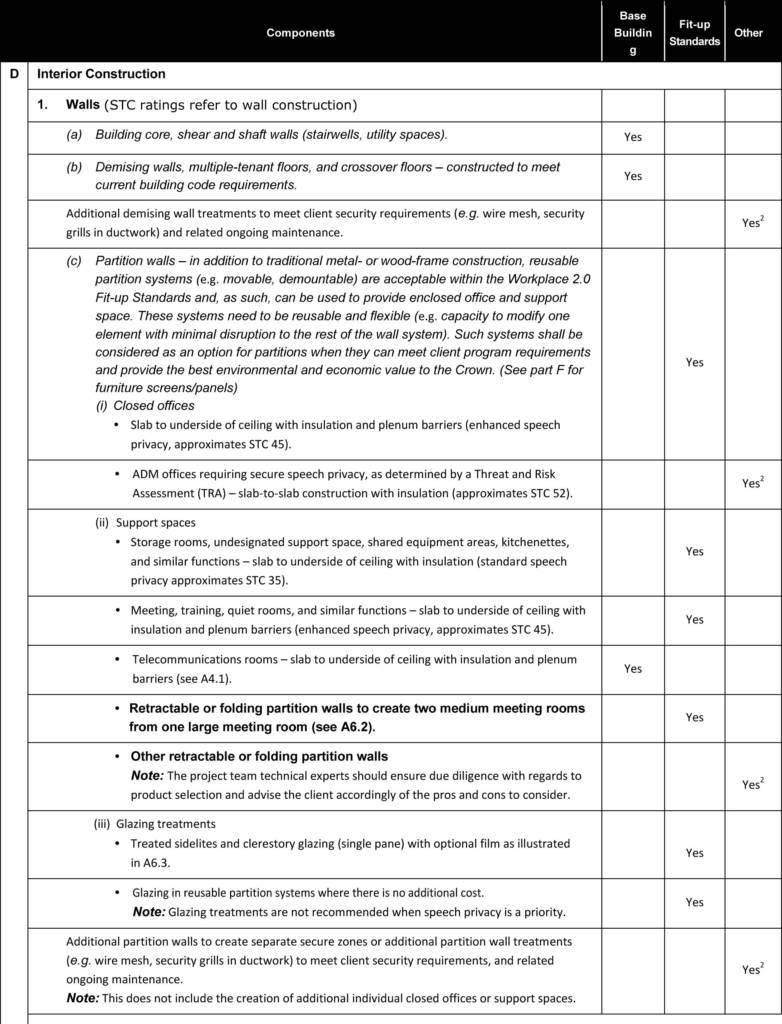

The construction required to achieve sound privacy in general-purpose office spaces is described in the table of section A3.3 of Workplace 2.0. Three levels of privacy are established: standard privacy, enhanced privacy, and secured privacy. Standard privacy is equated to a sound transmission class (STC) rating of 35 for the wall or, similarly, a ceiling attenuation class (CAC) rating of 35. (In the United States, the American equivalent to Workplace 2.0, General Services Administration [GSA] P100, Facilities Standards for the Public Buildings Service, has moved to noise isolation class [NIC] as a metric, rather than STC.) The wall should be insulated and extend from the floor slab to the underside of the suspended acoustic ceiling. This design leaves an open plenum above the suspended ceiling, meaning there are no upper walls to block sound transfer between rooms.

The Government of Alberta’s Department of Infrastructure (previously known as the Department of Public Works, Supply, and Services) has conducted extensive research on sound isolation between offices with suspended ceilings. (See K. Kruger’s “The Effect of Various Parameters on the Sound Isolation between Offices with Suspended Ceilings,” in Canadian Acoustics [16 (2)], 1988.) It states attempting to match the isolation performance of a ceiling to the demising wall can lead to disappointing results. It is important to know the combined effect of the wall and ceiling, along with any flanking that might be introduced through the latter, such as ventilation penetrations.

This low level of privacy (i.e. STC/CAC 35) is only permitted for unoccupied spaces, such as storage rooms and equipment rooms, and short occupancy spaces where privacy is not expected or required, such as kitchenettes. It can be deduced that ‘standard privacy’ as used in Workplace 2.0 is the same as ‘no privacy,’ and therefore unacceptable for spaces normally occupied by people while working.

Most regularly occupied spaces—such as enclosed, private offices, meeting rooms, training rooms, quiet rooms, and telecommunication rooms—should be constructed to achieve enhanced sound privacy, which is equated to an STC/CAC rating of 45. The higher-STC wall should be insulated and extend from the floor slab to the underside of the suspended acoustic ceiling. The main difference between standard privacy and enhanced privacy construction is the additional requirement of a plenum barrier extending vertically from the top of the wall to the underside of the slab above. This plenum barrier blocks the sound that transmits through the suspended acoustic ceilings, increasing the overall performance.

Another conclusion from the Alberta research is the most effective method of reducing sound transmission through the ceiling is to introduce a barrier into the plenum. The plenum barrier can be limited in length—it only has to be positioned above the wall between the two adjacent rooms. The plenum barrier does not need to extend around the entire perimeters of the rooms. A limited plenum barrier allows return air to still flow freely through the plenum.

When plenum barriers do need to surround the entire perimeter of the room, a hole of the appropriate size based on air volume and desired velocity should be cut in the plenum barrier over the door into the room. Workplace 2.0 requires solid-core wood doors, but does not call for perimeter seals or acoustic ratings. It even permits sliding doors, which are difficult to seal acoustically. It is highly likely the door will be the weakest link and transmit more noise than the return air opening in the plenum barrier above the ceiling.

Most specifiers, architects, interior designers, and contractors know how to design and construct an STC 45 wall. If they do not already have a standard detail on their wall-type sheet, they can go to any of a number of gypsum board manufacturers and quickly find details and test reports for an STC 45 wall. Conversely, there has been little to no information available to designers, in Workplace 2.0 or the industry’s literature base, about recommended materials and installation methods to use for a plenum barrier that, when combined with the ceiling, will perform at the same or higher level. This was one of the research goals of the Optimized Acoustics Research Program, a group for which this author serves as director. (The Optimized Acoustics Research Program is an ongoing, multi-year, multi-organization investigation into cost-effective means of designing and constructing interior architecture compliant with the acoustic requirements in industry standards, guidelines, and building rating systems. It began in 2014, and progress updates of the findings, such as this article, have been presented at and published in the proceedings of InterNoise 2015, NoiseCon 2016 and 2017, and Acoustics Week Canada 2015 and 2016, as well as published in Sound & Vibration and Canadian Acoustics. For more, visit www.optimizedacoustics.com[2].)

[3]

[3] [4]

[4]Plenum barrier materials and installation

Plenum barriers can be constructed of a variety of different lightweight materials, including:

- limp, mass-loaded vinyl (MLV);

- stone wool insulation with a foil facing;

- standard gypsum wallboard; or

- some combination of these materials.

This article omits research done on MLV plenum barriers because they generally do not perform as well as stone wool insulation and gypsum board plenum barriers, and plenum-rated MLV is much more costly than stone wool insulation and gypsum board. Additionally, MLV plenum barriers are more time-consuming to install.

While gypsum board plenum barriers are just as cost-effective as stone wool plenum barriers and work similarly well acoustically, the rigidity of the material can be a disadvantage in some buildings where there is floor/roof deflection, seismic joints, or expansion/contraction joints. Therefore, this article focuses on stone wool plenum barriers due to their low cost, relatively quick installation, pliability, and high sound isolation performance. (It is important to remember there is a very large difference between stone wool ceiling panels and mineral fibre ceiling panels. These are two separate materials with separate properties and performance. All research in this article was conducted with stone wool ceiling panels—readers should not assume the same results will be realized if they use mineral fibre ceiling panels.)

The goals of this most current phase of the Optimized Acoustics Research Program involve testing whether stone wool plenum barriers could:

- achieve the STC/CAC 45 rating required for the enhanced privacy level in Workplace 2.0; and

- be simplified to decrease material cost or installation time.

The test series investigated whether the thickness/weight of the plenum barrier could be decreased, and the foil facing and taping of vertical seams be eliminated.

A series of sound isolation tests was performed on a suspended, modular, acoustic ceiling system with and without various lightweight plenum barriers under laboratory conditions in a dual-room chamber. For the baseline test, the specimen comprised a metal tee-bar suspension system filled with 16-mm (5/8-in.) thick stone wool ceiling panels (CACpanel 23), but no plenum barrier above the demising wall. Subsequent tests added various lightweight plenum barriers.

In all cases, the ceiling grid ran continuously (i.e. uninterrupted) over the top of the laboratory’s central demising wall. A senior test engineer performed all tests at NGC Testing Services in Buffalo, NY. The laboratory is accredited by the National Voluntary Laboratory Accreditation Program (Laboratory Code 200291-0). Tests were performed according to ASTM E1414, Standard Test Method for Airborne Sound Attenuation Between Rooms Sharing a Common Ceiling Plenum, and ASTM E413, Classification for Rating Sound Insulation.

Figure 2 shows a double-layer, stone wool, plenum barrier being installed in the laboratory for testing. The stone wool material was 38 mm (1 ½-in.) thick with a density of 128 kg/m3 (8 pcf) and surface weight of 4.88 kg/m2 (1.5 psf). It is important to specify and obtain “actual” 128-kg/m3 (8-pcf) density material—data sheets for some materials contain “nominal” densities, which can be misleadingly high. (Density can be checked during the submittal review process.)

[5]

[5]For most of the tests, the plenum barrier panels had a fibre-reinforced foil facing on one side (Figure 3). The foil was oriented toward the open ceiling plenum, not into the small, interstitial air space between the two layers. The plenum barriers were mechanically fastened along the top edge using common, self-tapping, sheet metal screws with insulation washers into a common 41-mm (1 5/8-in.) wide metal channel attached to the test chamber overhead slab. Screws were spaced approximately 305 to 457 mm (12 to 18 in.) on centre (o.c.). Typically, each 610-mm (24-in.) panel had two screws along the top. This created a 41-mm air space between the two layers of plenum barrier board. The bottoms of the plenum barriers were only friction-fitted against the top track of the demising wall and the suspension system. They were not mechanically fastened, glued, or caulked. No neoprene gaskets, as seen in some project-specific plenum barrier details, were used.

Each panel was abutted to the adjacent panels along the sides with no overlap. For some tests, the vertical seams between adjacent panels were taped using 50-mm (2-in.) wide metal tape for sealing butt-joints. The 610-mm wide panels of each layer were staggered 305 mm so the seams were not aligned. This required a small cut along the bottom of one layer of the plenum barrier panels so they could slide down over the bulb of the suspension system and allow the bottom of the plenum barrier panel to sit on the top track of the demising wall.

No caulk or sealant was used. Small gaps around and between some of the plenum barrier panels were visible, but most were closed during installation due to the stone wool’s pliability. The panels were cut slightly oversized and then compressed vertically and laterally during installation, which helped prevent gaps. It was important the ceiling panels did not extend under the plenum barrier. Installed last, the ceiling panels abutted the bottom edge of the plenum barrier, locking it in place.

[6]

[6]Performance results

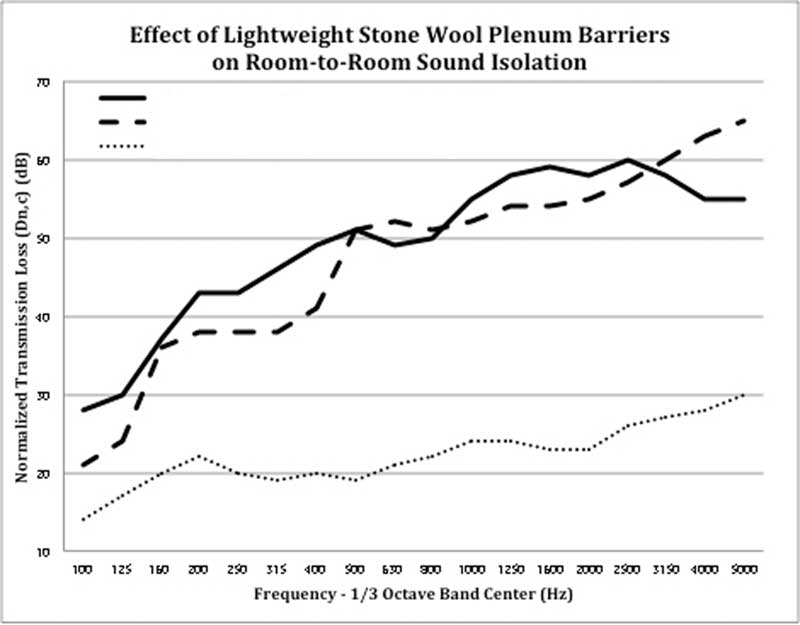

Figure 4 shows the improvement in sound isolation performance when double-layer stone wool plenum barriers are combined with a standard stone wool ceiling relative to the performance of the ceiling alone. In one case (bold dashed line), the ceiling systems included recessed light fixtures, open return air grilles, and supply air diffusers. Additionally, there was a supply air duct, three polyvinyl chloride (PVC) pipes, and three metal conduits in the plenum, penetrating the plenum barriers. (In this study, the penetrations were caulked, but over the course of three years of testing, the researchers have come to realize the caulking is unnecessary unless the installation was sloppy and resulted in gaps.) This most accurately represents actual applications in real buildings. The tested performance was STC/CAC 48—three points higher than the requirement of STC/CAC 45 in Workplace 2.0 for enhanced sound privacy.

When the plenum barrier was tested without the penetrations in the ceiling and plenum barrier (bold continuous line), the performance increased to STC/CAC 52. This is high enough to meet the most stringent level of privacy in Workplace 2.0, secured speech privacy, in Assistant Deputy Minister (ADM) offices. Numerous penetrations through the plenum barrier and ceiling should be avoided or acoustically remediated. For example, one might use suspended light fixtures instead of recessed light fixtures and use a return air grille silencer instead of leaving the grille open to the plenum.

Optimizing the results

When comparing the double-layer plenum barrier results of this phase to those from prior phases of the research program, the air space between the plenum barrier layers was found to substantially increase performance. Single-layer, monolithic slabs of stone wool (some with foil facings on both sides), with total thickness greater than the two thinner layers combined, performed significantly worse than a double-layer plenum barrier of thinner material and an interstitial air space.

The foil facing on the plenum barrier material improves acoustic performance significantly. Without it, the performance decreases 10 points. Only plenum barrier material with a foil facing should be used to meet Workplace 2.0 enhanced sound privacy requirements. Substitutions of unfaced materials will likely not result in the required performance.

Covering the vertical seams between plenum barrier panels with metal tape may not be necessary from an acoustic performance perspective. Adding the tape over the seams did not increase wideband STC/CAC or one-third octave band transmission loss. However, taping the vertical seams between the plenum barrier panels tied all of the pieces together into a system that appeared to be more durable and professionally installed. Covering the seams with tape may also help acoustic performance or durability on actual project sites if gaps occur between panels, or if the plenum barriers are penetrated by structural or mechanical elements inside the plenum. Caulking the plenum barriers is generally not required, but might be considered by installing contractors in limited locations if a large gap is observed.

Conclusion

The findings of this research show specifiers, architects, interior designers, and contractors the materials and installation methods for complying with the plenum barrier requirements and various sound privacy levels laid out in Workplace 2.0.

If a space is normally unoccupied, such as with a storage room, one can specify an STC 35 wall and stop it at the underside of a suspended ceiling. No plenum barrier is required. For private offices, meeting rooms, training rooms, and similar spaces, one could call for an STC 45 wall that stops at the underside of the ceiling (CACpanel 20 or higher) and place a double-layer, foil-faced stone wool plenum barrier as described in this article above the wall. Even with penetrations through the ceiling and plenum barrier for building services, the required performance will be met. For the limited spaces requiring secured privacy, using an STC 52 wall and limiting the penetrations in the ceiling and plenum barrier or extending the wall full-height from floor slab to floor slab or roof will achieve the goal.

Gary Madaras, PhD, Assoc. AIA, is an acoustics specialist at Rockfon and the director of the Optimized Acoustics Research Program. He helps designers and specifiers select the appropriate acoustical ceiling products and apply them effectively. Madaras is a member of the Acoustical Society of America (ASA), Canadian Acoustical Association (CAA), and Institute of Noise Control Engineering (INCE). He authors technical articles and speaks publically on the topic of optimizing acoustic experiences. Madaras can be reached at gary.madaras@rockfon.com[7].

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/09/Rockfon_NC-Albemarle_SonarCDX2x2-1200_201322-04.jpg

- www.optimizedacoustics.com: http://www.optimizedacoustics.com

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/09/fig1-2.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/09/fig2-1.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/09/Figure4.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/09/Figure5_RoomToRoom.jpg

- gary.madaras@rockfon.com: mailto:gary.madaras@rockfon.com

Source URL: https://www.constructioncanada.net/plenum-barriers-speech-privacy-workplace-2-0-fit-standards/