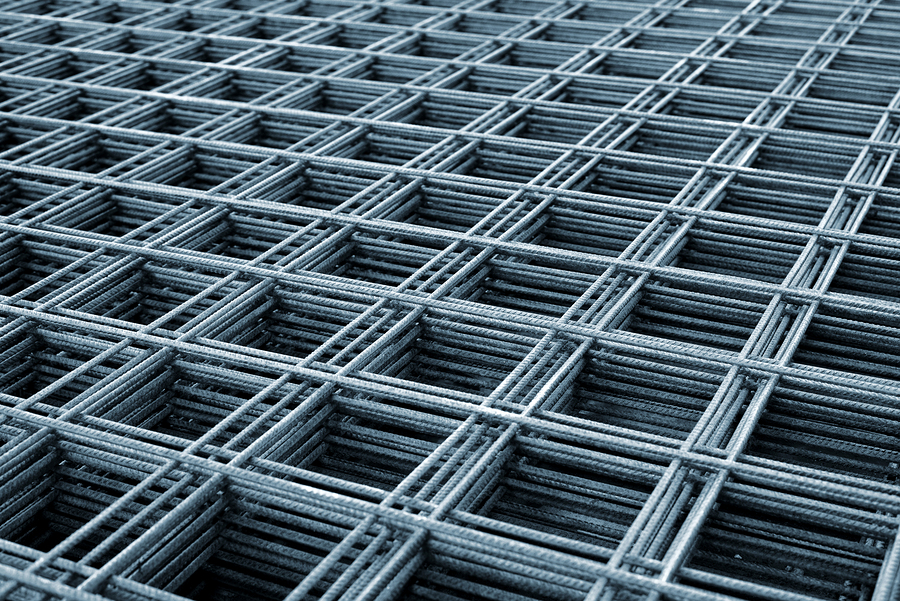

New standard for steel bars proposed

A newly proposed ASTM International standard will cover the protection of zinc-coated steel bars used in large infrastructure projects for concrete reinforcement.

ASTM WK46112, Specification for Zinc-coated (Continuous Hot-dip Galvanized) Steel Bars for Concrete Reinforcement, is intended to provide a high-performance, low-cost option for concrete structure protection. The standard will also describe the characteristics of steel reinforcing bars zinc-coated (galvanized) by the continuous hot-dip process in cut lengths or coils.

“Galvanizing is a proven and effective way to protect reinforcing bars from corrosion as it provides both barrier and galvanic protection to the steel substrate,” said ASTM member, and Construction Canada author, Gary Dallin. “It also increases the chloride threshold of steel reinforcing bars. A process to continuously galvanize reinforcing bars (CGR) at a significant cost savings compared to other corrosion-resistant reinforcing bar systems is now operating in two locations.”

Further, using a small amount of aluminum in a zinc bath, the process produces an almost pure zinc coating that adheres well and is resistant to corrosion in concrete.

“With no thick zinc-iron alloy layers, the coated bar can be bent, stretched, or twisted without cracking or flaking the coating, regardless of the total coating mass,” continued Dallin. “As a result, there is no zinc loss due to brittleness during forming in the field and repair requirements are minimal.”

The process allows all grades of steel to be galvanized without changing the mechanical properties.

ASTM WK46112 is being developed by Subcommittee A01.05 on Steel Reinforcement, part of ASTM International Committee A01 on Steel, Stainless Steel, and Related Alloys.