By Bill Wright

The introduction of super-large-format porcelain slabs into the Canadian market could redefine the countertop concept for high-end residential and hospitality projects including restaurants, bars, hotels, and high-rise condos. These slabs are also finding other interior design uses, including as fireplace surrounds.

For many years, granite and quartz have been the materials of choice for these applications for both functional and esthetic reasons. Now, porcelain components available in previously unavailable sizes—1620 x 3240 x 12 mm (63.7 x 127.5 x 0.5 in.)—are bringing new attributes to the table.

The designer-driven demand for slab options with the inherent characteristics of porcelain was a challenge. However, as manufacturing technology advanced, tiles grew from 300 x 600 mm (12 x 24 in.) to 600 x 1200 mm (24 x 48 in.). The engineering of these larger tiles paved the way for new opportunities in the slab market.

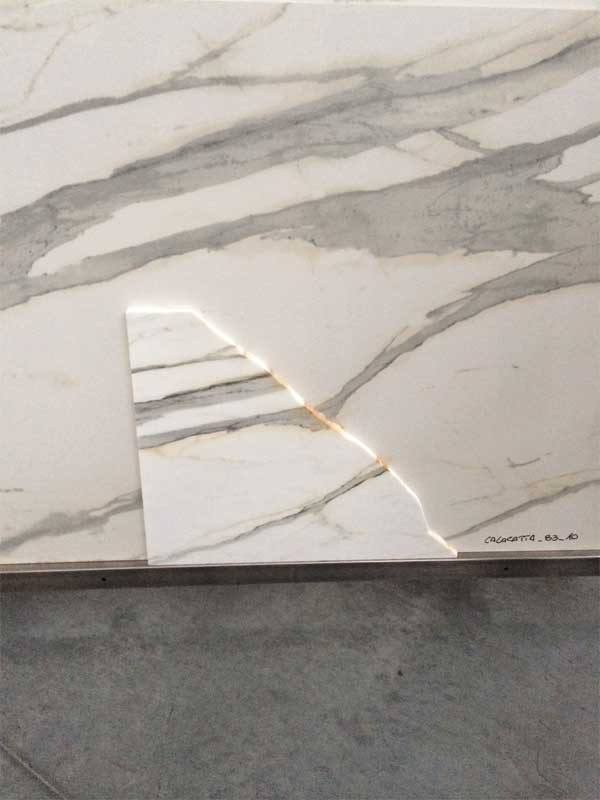

First developed in Italy and manufactured using a high-definition digital process, these porcelain slabs have excellent picture detail and crispness—a side-by-side comparison of these manufactured slabs with their natural counterparts will not reveal telling differences. Further, beyond esthetics, these types of products have many desirable technical qualities.

When comparing options that resemble white marble, a porcelain slab in the aforementioned dimensions is priced at about $40/sf retail. Quartz slabs at 1575 x 3200 x 20-mm (63 x 128 x 0.8-in.) come in at a similar price, whereas marble, depending on slab sizes and quality, can range from $80 to $120/sf in a 20-mm thickness. (Fabrication prices vary nationally from market to market.)

Strong as granite

Tested to Moh’s Scale of Mineral Hardness, with ‘1’ being the softest and ‘10’ being the hardest, 12-mm (½-in.) porcelain is a ‘9.’ Engineered quartz is typically rated ‘7’ on this scale, while granite comes in at an ‘8.’

The hardness rating of porcelain is the result of both the raw materials and manufacturing method. Porcelain tiles are a mixture of kaolin clay, quartz, and feldspar, which is blended, pressed, and then fired at 1200 to 1400 C (2192 to 2552 F). By comparison, the temperature of lava flowing from a volcano is about 700 to 1200 C (1292 to 2192 F). This combination of high heat and clay makes for a strong and durable finished material. Engineered quartz is pressed into slabs at a low heat, using a mixture of crushed quartz bonded together using resins, polymers,

and pigments.

Granite is a natural stone. It is a very hard igneous rock containing quartz, mica, and feldspar as its main mineral makeup. The high-heat firing process used to manufacture porcelain is similar to how granite is naturally created. This process is what gives porcelain its many superior qualities when compared to engineered quartz, and even the granite after which it is modelled.