Net-zero buildings made simple with ICF construction

The technology demonstrated its resiliency to natural disasters when the Category 5 Hurricane Michael struck the Florida panhandle in 2018. The storm destroyed dozens of buildings and took over 40 human lives. Yet, the sole ICF-built home on the coast managed to withstand the extreme force of the wind and water (Figure 2). The builders went beyond code to ensure life safety and the structure’s longevity in this high-risk region.

Labour savings

Net-zero status is all about minimizing the amount of energy spent in the long-term maintenance of a building. This philosophy ties into the human element of constructing the building. With fewer people entering the trades and experienced employees retiring, it is becoming more difficult to find skilled construction workers. Some manufacturers offer collapsible forms which make the lightweight product even easier to unload and move around a jobsite. Since ICFs combine multiple construction steps into one, there are fewer opportunities for errors and confusion in the handoff between trades.

Time savings

Insulated concrete forms can be installed in extreme weather conditions, minimizing downtime on the construction site. Crews can work through cold winters, expediting the time when interior work can begin, and subsequently, building occupancy. The operational turnaround is critical in education, hospitality, and residential structures to ensure owners see returns on their investment promptly. Schools typically have tight timelines to meet so that students, faculty, and staff can return for the academic year, and occupied structures want to start leasing out their units as quickly as possible.

Sustainability/energy

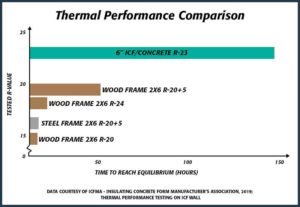

Insulated concrete forms are, in essence, continuous insulation (ci), which has no thermal bridging and little room for air infiltration. There is less airflow overall, which also results in added sound dampening. De Sylva calls it “conservation through insulation” with the EPS foam offering a far greater R-value compared to wood- and steel-frame construction.

Thermal performance testing shows ICF structures take the longest to reach a steady state when exposed to extreme temperatures. These results mean that if a building’s power is shut off and no heating/cooling mechanisms are in place, ICF structures would maintain their interior temperature longer than wood- and steel-frame buildings. An R-23 ICF building took over 125 hours to get to the point where the rate of heat being added to the interior of the ICF wall was exactly equal to rate of heat transmitting through the wall in reaction to the outside environment. This is commonly referred to as a “steady state.” In comparison, the highest rated wood-frame building, at R-25, only performed at an R-20 rating, and reached its steady state performance after only 50 hours (Figure 3).

The insulation value of ICFs lessens the pressure on a structure’s HVAC system during extremely hot or cold periods. All of this equates to a reduced carbon footprint.

Cost savings

The above-listed features of ICFs come together in financial gains for the contractor, designer, and building owner. With the speed of construction comes significant cost savings. Additionally, the lightweight nature of the foam form means less freight cost and easier shipping. Scott Chretien, project manager for Elite Building Group, used ICFs on the Howland Green Business Centre and noted the decreased weight meant they needed less expensive equipment.

“When you get into multi-storey buildings…not having to have a crane onsite is a huge cost saving for the builder and designers,” he said.

Today’s lumber market is fraught with increased cost and demand. EPS foam, on the other hand, offers a more stable cost alternative without having to cut down trees and damage existing ecosystems.

When net-zero buildings use ICF in combination with other environmentally friendly strategies, owners can even make money from their utility companies for the additional energy the structure produces through wind or solar power. Built in 2006, Richardsville Elementary School, located in tornado-prone Kentucky, was the first net-zero school in the United States. It used ICFs for greater safety and was able to reach its energy performance goals. The school was also within budget. It earns over $45,000 a year from utilizing and producing excess solar power. The incentives of net-zero status were so successful in this construction that it became the model for five new schools in the area.

For owner-occupied structures, the building owner can use the decreased energy consumption and cheaper heating and cooling costs as a tool to attract tenants. Whether it is an apartment complex, retirement facility, or office building, the owner can tout lower costs for the end-user. For example, Bronte West Condominiums in Milton (Ont.), another Howland Green construction project, advertises a $600/month cost savings for tenants in utility costs and condo fees because of the sustainable nature of the construction and operation of the six-storey building. Here, ICFs offered an estimated R-36 value, approximately three times greater than the Ontario Building Code (OBC) guideline.

With ongoing energy savings, the building owner has long-term operational cost savings over the lifespan of the structure, maximizing their investment. Greater insulating power also means there is less strain on mechanical and HVAC systems, decreasing the need for ongoing maintenance.

Conclusion

Although net-zero construction and the use of ICFs may seem like a departure from the comfort zone of the industry’s historical processes, the advantages of these new approaches far outweigh any initial fears of change or high price tags. The financial benefits over the life of the facility coupled with sustainability, durability, and labour- and time-savings make for a clear solution to everyday building challenges. Insulated concrete form technology offers a comprehensive system with all the performance characteristics and ease-of-install the design/build community demands.

![]() Keegan Still is a product manager at Nudura Insulated Concrete Forms, part of the Tremco Construction Products Group. He is responsible for ensuring Nudura properly addresses the needs of the marketplace as it relates to the Nudura product line offerings.

Keegan Still is a product manager at Nudura Insulated Concrete Forms, part of the Tremco Construction Products Group. He is responsible for ensuring Nudura properly addresses the needs of the marketplace as it relates to the Nudura product line offerings.

![]() Scott Carpenter has been in the construction industry for over 35 years, including 20 years in the insulated concrete form (ICF) industry. Currently the senior technical sales representative for Nudura in Ontario, he utilizes his in-field construction experience to help designers, engineers, and architects understand the benefits of ICFs in the construction market.

Scott Carpenter has been in the construction industry for over 35 years, including 20 years in the insulated concrete form (ICF) industry. Currently the senior technical sales representative for Nudura in Ontario, he utilizes his in-field construction experience to help designers, engineers, and architects understand the benefits of ICFs in the construction market.