Net-zero buildings made simple with ICF construction

By Scott Carpenter and Keegan Still

Building a net-zero structure is an ambitious goal but designing to this calibre is not as complicated as it might sound. Constructing with energy efficiency in mind takes co-ordination between all the project team members and product research to determine the most long-lasting and cost-effective methods to achieve the necessary standards. While insulation is not the sole contributor to a net-zero building, insulated concrete form (ICF) technology, in combination with other energy-saving practices, can improve a building’s energy efficiency while easing the construction process.

What is net-zero

First off, what does it mean for a building to be “net-zero”? This term, popularized in the early 2000s, refers to a structure that consumes and generates equal amounts of energy. Energy consumption includes heating, cooling, water use, lighting, and more. Creating clean, renewable energy and minimizing its use is feasible through an integrated approach of incorporating superior insulation between units and on the exterior building envelope, photovoltaics (PV) for electricity, water conversion and recycling, efficient fenestrations with low conductivity, and geothermal energy. Net-zero structures can be found in residential and commercial sectors, and are becoming more common in education, hospitality, and government projects. Using typical construction methods, energy costs can be particularly high for K-12 schools, apartment complexes, army barracks, and hotels, so a more efficient approach is now sought after for new builds. Dave de Sylva, P.Eng., founder of Howland Green Homes, puts it simply, “It is not that complicated…we can be different in how we build and have a positive impact on the environment.”

A building can even go “beyond net-zero” and achieve net-positive status, meaning the development produces more energy than it consumes. The Howland Green Business Centre in Markham, Ont., was the first net-positive office building in Canada. It attained this standing by employing:

- triple-glazed windows;

- ICFs, totaling 200 mm (8 in.) of expanded polystyrene (EPS) foam insulation;

- geothermal heating and air-conditioning;

- PVs (solar panels);

- high-efficiency appliances; and

- clean- and grey-water harvesting.

In addition to these and other strategies, energy monitoring is an important factor in net-zero construction. Real-time measurements allow for consistent review of energy consumption and production, enabling any necessary adjustments to be made and validating the owners’ investments.

For Howland Green, ICFs were a significant factor in saving the building owner and its future occupants heating and cooling costs.

Basics of ICFs

Insulated concrete forms consist of two continuous panels of EPS foam connected with a web system. The ICF forms are stacked to the desired building height, reinforced with steel, and filled with concrete. The resulting reinforced monolithic concrete walls can be used for several applications, including below and above grade. This method of building is compared to wood-frame, steel-frame, concrete masonry unit (CMU) block, or other structural masonry construction.

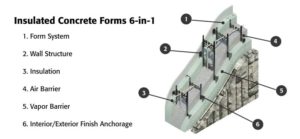

As building science becomes more advanced, the construction industry professionals are beginning to see the flaws in the previously tried and true methods of building. ICFs have filled that gap and offer six construction steps in one lightweight, easy-to-install form:

- Form system;

- Wall structure;

- Insulation;

- Air barrier;

- Vapor barrier; and

- Interior/exterior finish anchorage (Figure 1).

ICF manufacturers have a variety of form shapes to accommodate all types of building designs, and the EPS foam comes in various thicknesses to suit all energy code requirements and beyond.

Advantages of ICFs

In terms of net-zero construction, the advantage to building with ICFs is its sustainability aspects. This green-friendly method of building also comes with proven durability, labour-savings, and measurable time and cost savings for the design/build team and end-users.

Durability

The basic purpose of construction is building something that will last and keep occupants safe. Unfortunately, one frequently sees crumbling infrastructure where someone involved in the process must have cut corners. Insulated concrete form technology, on the other hand, has durability at its core. The foam insulation, rebar, and concrete interior ensure a structure that will last for centuries. ICFs offer maximum safety with a fire protection rating of up to four hours, and is proven to withstand winds of up to 400 km/h (250 mph).