Moisture concerns for flooring in concrete construction

By Patrick Henry Giles

Moisture vapour is a hot topic in any type of construction where there is concrete on, above, or below grade. Moisture vapour emissions through a concrete slab in any building can contribute to costly floorcovering failures and down time. Over the past 20 years, the frequency of moisture vapour emission issues has increased. Several contributing factors include:

- elimination of asbestos as an ingredient in resilient flooring;

- loss of solvents from adhesive and coating systems;

- increased use of water for easier concrete placement;

- fast-track construction schedules;

- absorptive aggregate in lightweight concrete; and

- lack of vapour retarders or having breeched under-slab vapour retarders.

Concrete moisture-related floor finish failures are responsible for multi-millions of dollars in damages annually and can occur both in new construction and renovation projects. The list of grievances is long: adhesive failures, floor coverings buckling and blistering, floorcovering replacement, blistering/delamination of non-breathable coatings and epoxies, tenant move-out and subsequent damage, injuries due to slips and falls, and litigation.

What causes moisture vapour migration?

Concrete requires water in order to be workable/finishable, as well as to facilitate the chemical reactions necessary for proper curing. Numerous factors can affect moisture levels in concrete.

Ground saturation

Concrete is somewhat porous, so it absorbs moisture from the ground below the slab. Environmental factors that affect exactly how much is absorbed include the depth of the water table and the soil gradation.

Temperature and humidity differences

Water vapour from damp soil will diffuse and condense on a cooler concrete slab surface, and at a lower relative humidity (RH).

Pre-pour preparation

If an under-slab vapour retarder is used and the coarse fill/blotter layer is wetted, the moisture will only have one way to escape—through the top of the slab. There are two ASTM standards regarding under-slab vapour retarders:

- ASTM E1745, Standard Specification for Plastic Water Vapour Retarders Used in Contact with Soil or Granular Fill under Concrete Slabs; and

- ASTM E1643, Standard Practice for Selection, Design, Installation, and Inspection of Water Vapour Retarders Used in Contact with Earth or Granular Fill Under Concrete Slabs.

Original moisture content

Any moisture used in the mixing of the concrete will take anywhere from six weeks to more than a year to move through the concrete before the slab reaches an acceptable dryness level.

Determining moisture levels

It should be noted moisture vapour migration and hydrostatic pressure are two separate issues and are measured differently. Hydrostatic pressure is liquid water pushing through the concrete. It is under pressure and measured in PSI relative to feet of water head (or, in metric, kilopascals to metres of water head). Hydrostatic water follows the course of least resistance and moves laterally.

Moisture vapour, on the other hand, is a gaseous form of water measured in pounds per 1000 sf over 24 hours. (It can also be measured as a percentage of relative humidity deeper in the concrete itself.) There is little pressure associated with moisture vapour. Due to this, as well as the fact there is little actual water, moisture vapour has little to no lateral movement.

Over time, there have been numerous tests claiming to measure moisture vapour in concrete slabs. ASTM has limited this list to three when measuring for appropriate moisture levels for floor finish adhesives:

- RH: ASTM F2170, Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using In-situ Probes;

- RH: ASTM F2420, Determining Relative Humidity on the Surface of Concrete Floor Slabs Using Relative Humidity Probe Measurement and Insulated Hood; and

- calcium chloride: ASTM F1869, Standard Test Method for Measuring Moisture Vapour Emission Rate of Concrete Subfloors Using Anhydrous Calcium Chloride.

Moisture mitigation options

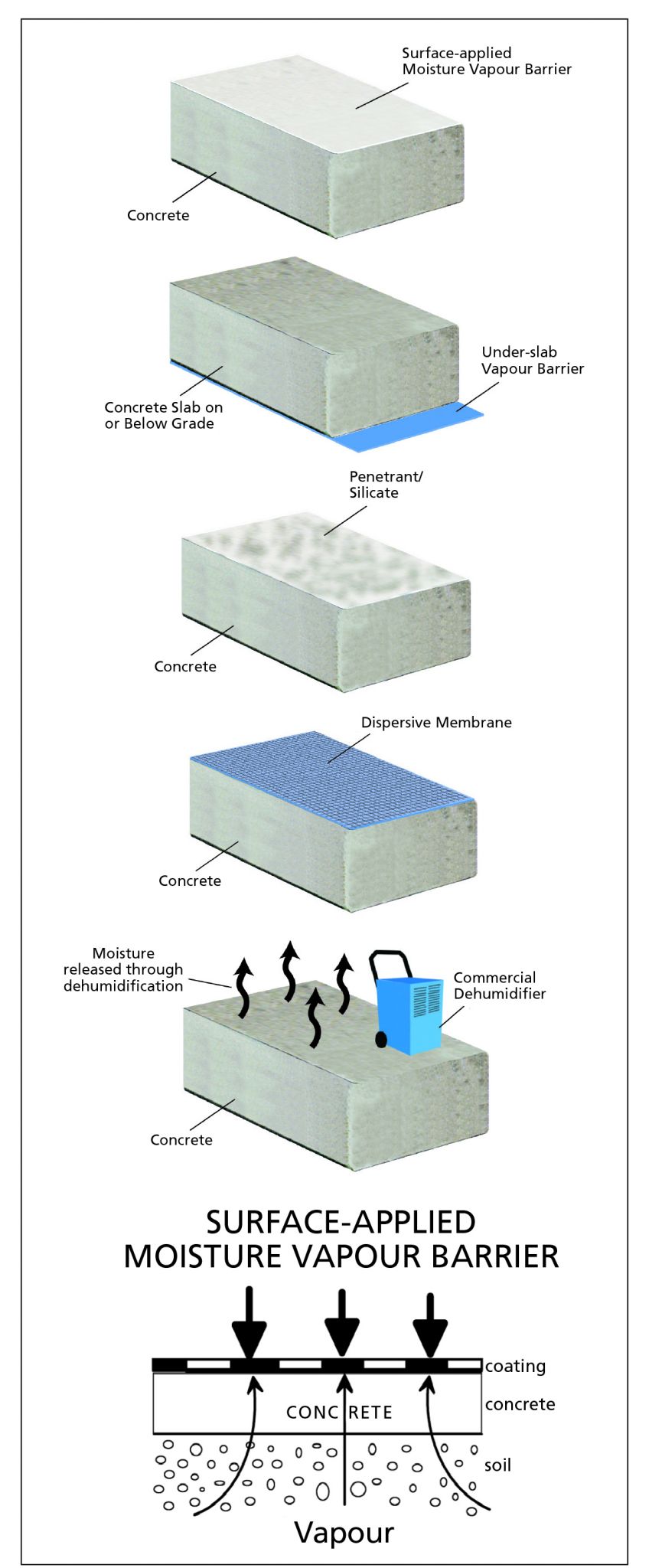

There are numerous barrier options to reduce moisture vapour emissions migrating through concrete, lowering the likelihood of an adhesive failure. These include:

- below-slab barriers;

- a penetrant/silicate;

- dispersive membranes;

- dehumidification; and

- surface-applied barriers.

Each is different in how they potentially prevent moisture from reaching a finished floor, although most have idiosyncrasies that preclude complete protection from moisture vapour emissions.

Below-slab barrier

A below-slab barrier is applied underneath the slab before the concrete is poured. While this method may seem like a simple choice, there remain some potential moisture-related concerns. For example, since it is placed under the slab, it does nothing to address moisture and pH levels in the slab itself—both these factors are proven to result in adhesive failures. Additionally, below-slab barriers are breachable, meaning rocks, shoes, wire, or rebar can cause tears and holes, compromising the barrier.

Penetrant/Silicate

Designed for exposed concrete, penetrants or silicates offer preventing moisture vapour emissions as an additional benefit. One of the largest issues with this type of system is adhesives will not bond to a penetrant/silicate—this means adhesive manufacturers require removal before application of their adhesive. It is also a breathable system, which allows moisture to penetrate through to the floorcovering.

Dispersive membranes

A dispersive membrane sits atop the slab, preventing moisture from coming in direct contact with the floor goods. The mat’s flexible nature is not conducive to heavy traffic; it also limits the choice of flooring finish since it does not provide a solid substrate. This system does not actually stop the moisture from coming through the slab, so the moisture can actually condense on the organic material left on the concrete, leading to potential bacterial growth. Further, since moisture is still present, chemical reactions between moisture and elements in concrete create the high pH environments resulting in floorcovering adhesive failures.

Dehumidification

Dehumidification is probably the easiest moisture mitigation system on the market, but can also be the most unreliable for long-term moisture issue prevention. A commercial dehumidifier is placed on the slab and used to remove moisture. This process only addresses moisture in the top of the slab, yet moisture can exist throughout.

Dehumidification may or may not be successful, and there is no guarantee it will work as a permanent solution. This method is also unpredictable, as there is no set time on how long it would take to remove enough moisture to install floor finishes. It cannot be used on new concrete, as it accelerates drying which can cause cracking, curling, and physical property loss. Further, since it addresses the symptom rather than the source, it lacks an extended warranty as moisture may reappear.

Surface-applied moisture vapour barriers

Surface-applied moisture vapour barriers are applied to the top of the slab, offering complete, durable coverage from moisture vapour emissions. As the barrier is applied to the top of the concrete, it stops moisture vapour emissions coming from concrete, the ground, and environmental conditions. This type of system also offers protection from the high pH levels associated with adhesive failures due to moisture vapour emissions.

Installation is permanent, with application in most jobs finished within a few hours. Most of these systems can be installed on old or new concrete as recent as five days old. For a surface-applied moisture vapour barrier to be successful, it is essential the system meet the guidelines that are established in ASTM F3010-13, Standard Practice for Two-component Resin Based Membrane-forming Moisture Mitigation Systems for Use Under Resilient Floor Coverings.

Creating a standard for surface-applied moisture mitigation systems

There are not only numerous types of moisture vapour barriers, but also many options within each category—this means making sense of what each product claims can be difficult. To address both the prevalence of varied and inconsistent information, as well as floorcovering failures resulting from inadequate moisture vapour barriers, ASTM Committee F06 on Resilient Floor Coverings developed and approved the aforementioned ASTM F3010-13, which is the only moisture vapour barrier system it recognizes.

This new standard applies specifically to two-component, resin-based moisture mitigation systems. It discusses the application of these moisture vapour barriers over concrete floors with high moisture content. ASTM F3010-13 also discusses the properties and performance requirements of these products before installation of resilient floorcoverings.

To meet ASTM F3010-13, these products need to meet the following criteria:

- reduce moisture transmission to no more than 0.1 perm (with perm defined as grains/hr/sf/in•Hg);

- mil thickness required to meet the 0.1 perm rating specified by manufacturer; and

- be tested in accordance with ASTM E96, Standard Test Methods for Water Vapour Transmission of Materials.

ASTM F3010-13 does not cover:

- systems chemically reacting with any component of the concrete to form a gel or crystalline substance within the slab;

- penetrating, water- or solvent-based compounds forming a discontinuous membrane on the concrete surface; and

- water-based membrane-forming systems.

Trends in concrete construction

Most people associate moisture vapour with slabs on or below grade, but as this article discusses, moisture can also be present in slabs that are suspended or above grade—particularly on non-vented metal decking. Moisture in these slabs is mostly due to the water content when it was first mixed, concrete thickness, curing method, or environmental conditions.

Additionally, use of non-vented metal pan decking also increases concrete drying time by sealing the bottom of the slab, which prevents the release of excess moisture through this location, so residual moisture can only escape up. To keep concrete high-rise projects on track, or even accelerate the construction schedule, some contractors across North America are turning to a relatively new system.

The concrete contractor is installing the concrete, but leaving it approximately 19 mm (¾ in.) below the specified height. In as little as five days, a surface-applied moisture vapour barrier is installed over the new concrete, preventing the moisture in the still-curing concrete from migrating to the top of the slab.

A self-levelling underlayment is then installed over the moisture vapour barrier, resulting in a moisture vapour-protected flat floor. This underlayment is fast-drying, and can be walked on within a couple of hours. Since it dries quickly, the floor goods can be installed within 72 hours—in other words, weeks before traditional high-rise concrete construction—resulting in overall project cost savings.

Conclusion

Moisture vapour migration through concrete slabs can result in costly flooring failures. Numerous aspects influence just how much moisture vapour there is in the concrete, both short-term and long-term.

While there are many different types of moisture vapour barriers, it is strongly recommended a surface-applied moisture vapour barrier is chosen to meet ASTM F3010. When this type of system is installed in fast-track high-rise concrete construction, contractors can also use a fast-drying self-levelling underlayment, resulting in flat or level floors with minimal floor preparation required from the flooring installer. Reduced overall project costs, as well as long-term savings, should be taken into consideration with this type of system since future flooring issues due to moisture will be minimized. This recommendation applies to finishes ranging from wood, resilient products, and epoxies to rubber, but does not apply to ceramic or stone.

Patrick Henry Giles is the vice-president of technical R&D at Maxxon Corporation, overseeing the company’s fire and acoustical testing, product development, and in-house laboratory, along with its quality assurance department and various internal regional representatives. With Maxxon for 30 years, he previously worked for a decade as a senior technologist at a local acoustical consulting firm. Giles holds three patents for sound control and underlayment technology, and sits on numerous committees and industry organizations to share his knowledge of the latest technologies. He can be reached at pat@maxxon.com.

Patrick Henry Giles is the vice-president of technical R&D at Maxxon Corporation, overseeing the company’s fire and acoustical testing, product development, and in-house laboratory, along with its quality assurance department and various internal regional representatives. With Maxxon for 30 years, he previously worked for a decade as a senior technologist at a local acoustical consulting firm. Giles holds three patents for sound control and underlayment technology, and sits on numerous committees and industry organizations to share his knowledge of the latest technologies. He can be reached at pat@maxxon.com.