Meeting restaurant ceiling requirements

Back-of-house options

Several manufacturers now offer unfaced, premium-grade mineral fibre panels for use in commercial kitchens. They are offered as cleanable and disinfectable materials. One leading manufacturer recommends cleaning either by vacuuming or light wiping with a mild detergent, and disinfection by fogging with a special disinfectant/cleaner, spraying with highly dilute bleach, or wiping with dilute hydrogen peroxide. The manufacturers’ data sheets and warranties indicate the panels are not to be cleaned any more aggressively than lightly wiping them with a damp cloth.

Other ceiling candidates include stainless steel, anodized or painted aluminum, thermoformed plastic panels, and glass fibre composite panels. These products perform well in humid and dirty environments. They can be washed in place or, if necessary, removed from the ceiling grid to be soaked or hosed (Figure 4).

Open kitchens

The concept of an open or exposed kitchen is not new. Anyone who has watched a short-order chef flip burgers on the other side of a lunch counter or admired the flourishes of a sushi itamae at the cutting board has experienced their performance in an open kitchen. Their polished motions, the sizzle of the grill, and the wafting aroma is part of the dining experience. An expanded variety of dining establishments have placed some or all of their culinary areas in view of their patrons. The concept is growing, especially in fine dining establishments, as guests have grown more cautious about food quality and purity. Restaurateurs see transparency as a way to allay these fears. An open kitchen can also be a form of entertainment.

One approach is to differentiate the seating and culinary zones by using different types of ceilings, such as a lay-in ceiling over seating juxtaposed against a hard-lid soffit above food prep. The alternative is to use a single ceiling product throughout the room—one that is attractive and acoustical, yet also impervious and cleanable. The latter approach has the advantages of visually unifying the space, reducing construction costs, and facilitating relocation of the culinary area without needing to remodel the ceiling. Examples range from the elegant antipasto bar (Figure 5) to the no-nonsense service line (Figure 6).

Strength and cleanability

Standardized tests can be used to evaluate the relative merits of various ceiling products to withstand the high demands placed on restaurant kitchens with regard to hygiene and the ability to withstand cleaning.

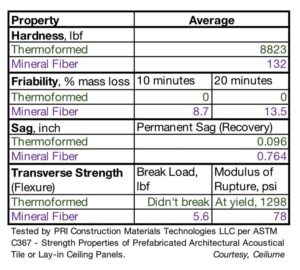

For example, ASTM C367/C367M, Standard Test Method of Strength Properties of Prefabricated Architectural Acoustical Tile or Lay-in Ceiling Panels, is the ceiling industry’s recognized consensus standard for measuring four characteristics of ceiling products:

- Hardness is determined by the depth of an indentation made by a dropped weight. Greater hardness correlates to a panel’s increased resistance to impact and abuse.

- Friability measures the weight of material which erodes when specimens are placed in a rotating tumbler. Less weight loss indicates a reduced likelihood of edge damage when a panel is installed or handled during maintenance. Some friable ceiling materials are stable when intact, but when damaged may shed respirable fibres, which may include silica fibre, a hazardous material. For example, one major manufacturer includes the following warning label on its mineral fibre products: “Warning. This product contains man-made vitreous fibers. Possible cancer and respiratory tract hazards can cause respiratory, skin, and eye irritation.” Materials tested with greater hardness and/or lower friability reduce the likelihood of fibre shed.

- Sag resistance is determined by exposing a product to high humidity, allowing it to return to normal ambient conditions, and measuring how much permanent sag occurs. Panels with less sag indicate greater resistance to moisture.

- Transverse strength indicates a panel’s resistance to breakage from impact or being dropped.

Figure 7 provides an example of test results.

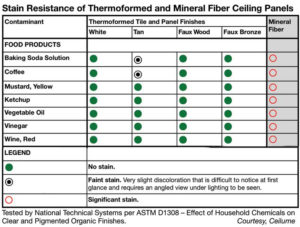

ASTM D1308, Standard Test Method for Effect of Household Chemicals on Clear and Pigmented Coating Systems, can be used to compare stain resistance to various food products. Reagents are applied to a specimen, allowed to sit, cleaned using prescribed techniques, and then visually examined (Figure 8).

Unfortunately, some ceiling manufacturers make vague representations about the performance of their products without explaining the basis for their claims. While ASTM International cautions lab testing does not necessarily replicate field conditions, test results can be used for comparison and should be requested when considering products for which the specifier does not have first-hand experience.

Ceilings à la carte

In addition to front- and back-of-house ceiling entrees, some facilities also require a selection of ceiling hors d’œuvres for ancillary spaces. For example, entryway vestibules may require hold-down clips to prevent suspended ceiling panels from uplift due to changes in air pressure when doors open. Toilet room ceilings, ranging from mundane to elaborately themed designs, should be selected with regard to potential exposure to water and humidity, as well as the rigours of frequent and aggressive cleaning. Back-of-house areas such as dry storage and staff break rooms can be ceiled with less robust products than culinary areas. The front-of-house may also have a range of requirements for ceilings in lobbies, lounges, meeting rooms, and other settings.

With so many types of ceilings on the menu, the challenge is to find the perfect recipe for a project’s success.

Notes

1 “Acoustic ceiling” and similar terms refer to all types of ceilings which have noise-reducing properties. It is not a synonym for “mineral fibre ceiling.” If the term is used in construction documents, the product requirements must be clearly identified in project specifications.

Authors

Ben Carr is the customer service manager for ceiling manufacturer Ceilume. Carr can be reached via www.ceilume.com/pro.

Ben Carr is the customer service manager for ceiling manufacturer Ceilume. Carr can be reached via www.ceilume.com/pro.

Eric Marino is the owner of Elegant Ceilings and Walls, Inc., a multi-line interior product showroom in Saint-Léonard (Montréal), Quebec. Marino can be reached via www.ceilingsandwalls.com.

Eric Marino is the owner of Elegant Ceilings and Walls, Inc., a multi-line interior product showroom in Saint-Léonard (Montréal), Quebec. Marino can be reached via www.ceilingsandwalls.com.

Steven H. Miller is a construction document technologist (CDT) and freelance writer specializing in issues in the construction industry. Miller can be reached at steve@metaphorce.com.

Steven H. Miller is a construction document technologist (CDT) and freelance writer specializing in issues in the construction industry. Miller can be reached at steve@metaphorce.com.