Measuring wood’s moisture content

How wood holds moisture

Wood’s hygroscopic nature stems from its individual cells that are designed to soak up the moisture a living tree needs as it grows and matures. Those cells do not lose their capacity to hold and release moisture once the tree is converted into usable lumber.

The cells hold moisture in two ways:

- free water, in which the cell cavities can hold moisture in both its liquid and vapour states.

- bound water, in which the cell walls, made up of cellulose fibre called microfibrils, hold water that is chemically bonded or essentially ‘bound’ with the cellulose molecules.

The amount of water in the wood, or the MC percentage, is the combined total of both free and bound water. However, these two forms of water do not impact wood in the same way. It is the movement of bound water, either into or out of the wood, that has the most significant impact on whether the wood is warping, swelling, shrinking, or cracking.

The cell walls expand or shrink depending on the amount of water they hold. In contrast, cells holding free water do not change their shape with any shift in MC in the cell cavities and open spaces. However, free water usually occurs at moisture levels much higher than is used in construction.

The effect of ambient temperature and RH

Ambient conditions (temperature and RH) largely dictate whether the wood cells take on or release moisture. Air temperatures affect the amount of moisture air can hold. Warmer air can hold more moisture than colder air. RH indicates how much moisture the air is holding as a percentage of what it could hold.

Wood absorbs or releases moisture in response to ambient RH. When the ambient RH is low relative to the wood’s MC, moisture gets drawn out. When RH is high relative to the wood’s moisture level, the material will suck moisture from the environment.

Wood reaches a point of equilibrium moisture content (EMC) when it is neither absorbing nor releasing moisture. Attaining EMC requires relatively stable ambient conditions so the moisture within the wood can eventually match its surroundings. When ambient conditions are constantly changing, so will the MC of the wood.

In construction projects, it is important to work with wood that has been dried to the proper MC and has attained the point of EMC. Inside heated buildings, this will often mean aiming for an MC of about six to eight per cent, although this is merely a rule of thumb that may vary according to different environmental conditions and the geographic location.

How to measure wood MC

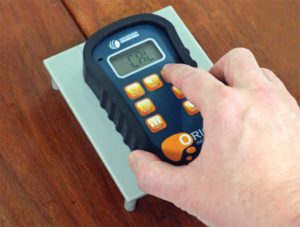

Although other methods exist, the simplest and fastest way to get an accurate measurement of wood’s MC is to use a handheld moisture metre. Two types are available:

- resistance or pin-style; and

- dielectric or pinless metres.

When using a pin metre, two pins are inserted into the wood and the metre measures the electrical resistance between the pins. Since moisture conducts electricity, higher electrical resistance corresponds with drier wood, and conversely, lower electrical resistance corresponds with wetter wood. One drawback to pin metres is they are intrusive, leaving unsightly pin holes in the wood. Another drawback is they can be somewhat slow and cumbersome to use. This is especially true with hardwoods where inserting pins to the depth necessary for an accurate reading can prove difficult.

In contrast, pinless metres are extremely fast to use. Since they employ a flat plate in contact with the wood surface to detect conductivity using electromagnetic waves, they leave no damaging holes in the wood. They can also be used for a broader range of MC measurements than most pin-style metres. One drawback of pinless metres is that some of them may be unduly affected by surface moisture or the ambient temperature.