Interweaving sustainability, learning, and culture at Mohawk College

Enclosure performance

Taking a holistic approach to the building’s design, the windows, walls, and roofs were treated as a single system, with an overall effective heat loss performance target being assigned. This target required the architecture team to focus not only on wall insulation and window U-values, but also on the impact of glazing ratios on the whole-building-envelope heat loss. A very detailed analysis of the envelope assemblies ensued.

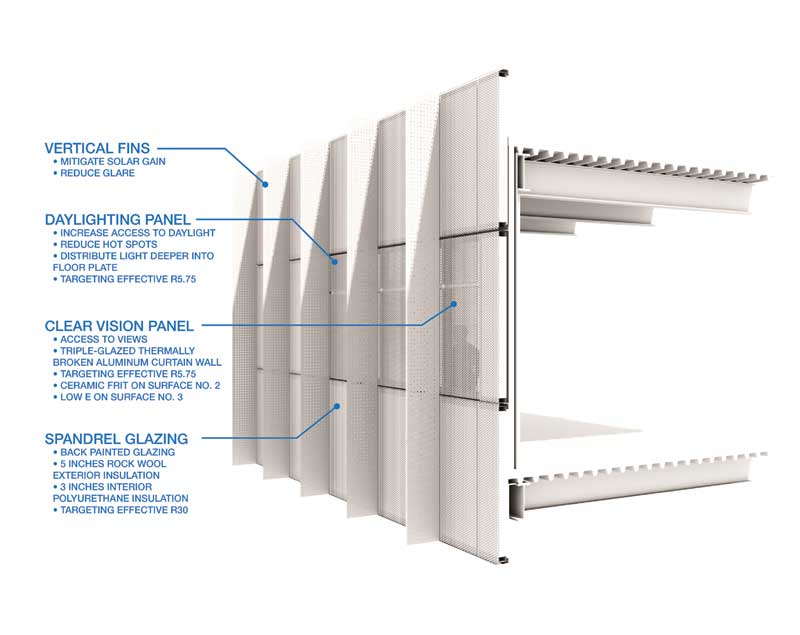

The high-performance, unitized, triple-glazed curtain wall assembly—specifically augmented for this project—will employ rubber isolation gaskets between unit frames to help ensure the lowest possible heat transmission. The system, among other innovative aspects, helps prevent flanking, which is when heat moves laterally between aluminum frames. Glazing units with multiple low-emissivity (low-e) coatings, ceramic frit, and argon fill will combine with a highly studied window-to-wall ratio to control solar loads and reduce cooling demand. (The ratio of vision glass to opaque wall element is an important index of the thermal efficiency of the total building envelope system.)

High-performance envelope design details

To increase the stability of the interior environment relative to the climate loads and ensure the HVAC systems work the minimal amount of time, the facility’s thermal performance has been designed to achieve an effective average value of approximately RSI 1.76 W/m2/C (R-10 Btu/sf/F).

The glazing is a unitized triple-glazed aluminum system, with specialized framing and gasketing. All vision glazing targeted a thermal performance of U-value 0.8 W/m2/C (R-7). In addition to the curtain wall, an insulated precast sandwich panel system was selected to assist the construction manager in accelerating the construction schedule. The panels have 100 mm (4 in.) of encapsulated polyisocyanurate (polyiso) insulation with 75-mm (3-in.) sprayed polyurethane foam (SPF) insulation backup. The system can be erected quickly, with excellent quality, and sealed from the interior for exceptional field value thermal performance.

Roofs are designed to a thermal performance of RSI 7.01 (R-40). The assembly is designed as a conventional system, comprising two-ply styrene-butadiene-styrene (SBS) modified bitumen (mod-bit) membrane, polyiso insulation board, and vapour barrier on a sloped structure with local tapered insulation board. The system will be cold-applied adhered, with a high-reflectivity top sheet.

Structural framing and special structural features

As fitting for Hamilton, the Steel Capital of Canada, the building superstructure will be structural steel. Floor composition will be 90 mm (3 ½ in.) of concrete on a 75-mm (3-in.) steel deck for a total depth of 165 mm (6 ½ in.). Steel beams will support the deck and concrete using composite action. The composite action and use of dead-load camber on the beams will minimize the depth of the beam required to carry the floor load and control deflection on the long spans. This will allow for maximum open space and future flexibility.

The solar PV support system will be a combination of structural steel and proprietary supports by the solar panel fabricator. To maximize the area of the solar collection, a unique design for the solar farm will span across the building in the east−west direction. The wing-shaped structures will be supported on a series of uniquely designed steel sections, which will be fully exposed to add a unique aspect and teaching potential.