Innovations in drywall finishing

Jobsite conditions

Following industry guidelines and recommendations will make joints disappear behind a smooth, flat surface. One key element to achieve these results is allowing each layer of joint compound to completely dry before starting on the next step. That said, how long it takes for each layer to dry depends on the temperature and relative humidity (RH) levels within the space.

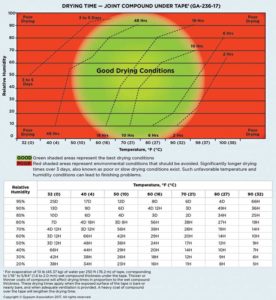

Within GA-216, it is noted “drying-type compounds shall be allowed to dry thoroughly…before sanding or the application of additional coats.” This document also references GA-236, Joint Treatment Under Extreme Weather Conditions, which describes the impact of temperature and RH on joint compound materials and provides guidance on how to minimize potential problems.

Handling joint treatment under extreme weather conditions

The term “extreme weather” in the GA-236 title may be misleading because, in Canada, there are many times of the year where “extreme” conditions exist when talking about drying of joint compound. Progress on the job does not need to stop if the temperature or RH levels are not within the optimal range for proper drying of joint compound. Understanding and adjusting site conditions is possible, but recognizing it needs to be done is the first step.

A chart and table within GA-236 shows the effect of RH and temperature on drying time for each coat of joint treatment. To achieve the best results, each coat must be allowed to thoroughly dry before applying another coat. Unfavourable temperature and RH conditions may require a drying time of more than three days per coat. It is important to keep in mind that slow or poor drying conditions often result in problems with the final finish.

In hot, dry weather, joint compound dries too quickly. Reducing ventilation is one way to help maintain the indoor humidity level as well as protect wet joints from direct air movement which accelerates drying and can cause fissures and edge cracks.

In wet, humid weather, joint compound dries very slowly. It could take days for each coat to thoroughly dry; therefore, dehumidifiers can be used to improve RH levels and get back into the optimum range for drying.

In cold weather, heat needs to be provided. It is important to ensure room temperature is kept between 10 and 35 C (50 and 95 F) for 48 hours beforehand, and continuously until materials are completely dry. Heaters should not be allowed to blow directly on wall surfaces as this can result in the compound drying too quickly and causing cracking and localized delamination to occur. Some heaters can also introduce excessive moisture into the air; therefore, RH levels should be monitored, and sufficient ventilation should be provided.

Jobsite monitoring

Some gypsum manufacturers offer installers monitoring services on select projects. By monitoring jobsite conditions using data loggers before, during, and after application, finishing experts can help contractors understand their specific conditions and provide solutions to achieve and maintain optimum drying conditions, preventing many common finishing problems.

Having to repair any finishing problems after the job has been completed is not good for a contractor’s reputation or pocketbook. Renting fans, dehumidifiers, or adding electric heaters is a fraction of the cost; therefore, understanding what optimal conditions should be met and how to maintain them are the keys to success.

Conclusion

As the tradespeople of yesterday retire and construction schedules are compressed, the industry may not have the same level of artistry in the field or the time for attention to detail; using advanced products and tools can not only help offset these challenges but also ensure high quality, long-term results can still be achieved. Today, the choice of products and an understanding of how to prevent problems can have a major impact on the overall impression of a finished project, as well as how it stands up over time.

Authors

Michelle Maybee, P.Eng., CTR, is an architectural solutions manager for CertainTeed Canada, based in eastern Ontario. She has been in the building products industry for more than 20 years supporting the design community in the province. Maybee is a member of Construction Specifications Canada (CSC), the Gypsum Association (GA), the Building Envelope Council Ottawa Region (BECOR), and the Canadian Green Building Council (CaGBC). She can be reached at michelle.maybee@saint-gobain.com.

Michelle Maybee, P.Eng., CTR, is an architectural solutions manager for CertainTeed Canada, based in eastern Ontario. She has been in the building products industry for more than 20 years supporting the design community in the province. Maybee is a member of Construction Specifications Canada (CSC), the Gypsum Association (GA), the Building Envelope Council Ottawa Region (BECOR), and the Canadian Green Building Council (CaGBC). She can be reached at michelle.maybee@saint-gobain.com.

Darlene Helfrich, IDT, CTR, has spent more than half her career as a manufacturer’s technical representative. Previously, she spent many years as an interior designer in Edmonton, Alberta, working with a few different architectural firms. Helfrich has been actively involved in the Edmonton Construction Specifications Canada (CSC) chapter for more than 24 years.

Darlene Helfrich, IDT, CTR, has spent more than half her career as a manufacturer’s technical representative. Previously, she spent many years as an interior designer in Edmonton, Alberta, working with a few different architectural firms. Helfrich has been actively involved in the Edmonton Construction Specifications Canada (CSC) chapter for more than 24 years.