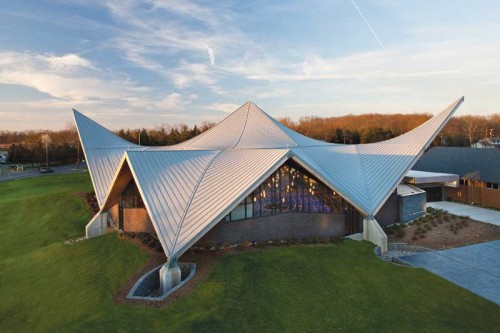

Improving building performance with sustainable metal roofing

By Scott Kriner, CSI, AIA, LEED AP

In the last 10 to 12 years, the benefits of sustainable design and green building practices have proven effective in increasing the efficiency of energy, water, and materials use. Buildings designed by these standards also produce less carbon emission, which reduces environmental impact. Additionally, people who live and work in green buildings tend to be healthier and more productive.

The push to both conserve existing resources and reduce energy consumption is targeted on improving overall energy performance, particularly in commercial buildings. According to statistics from the U.S. Green Building Council (USGBC), the building industry is the biggest energy user in North America, accounting for approximately 39 per cent of the primary energy and 71 per cent of the electricity used overall.

In determining how to improve the performance of the entire building envelope, the first step is to evaluate what is often the least energy-efficient component—the roof. Many roof systems have R-values as low as R-5 or R-10 (0.9 or 1.8 RSI). According to energy statistics from the U.S. Department of Energy’s (DOE’s) Oak Ridge National Laboratory (ORNL), about one-third of a typical building’s energy goes toward heating and cooling, and half of that can be attributed to heat gain or loss through an inefficient roof.

Specifying cool metal as a roofing material can help improve energy efficiency while adding environmental benefits inherent in the material. Metal roofing has high recycled content, and is recyclable or reusable at the end of the building’s useful life. This lowers the demand for raw materials and reduces construction waste. Metal roofs are also designed to last 50 years or more, depending on the substrates, paints, and coatings. Natural metals such as zinc and copper that have no added exterior paint or coating will form a natural patina that inherently protects the surface and maintains its esthetic appeal for a long time.

Photo © Janet Kimber. Photo courtesy Vicwest

Good air quality is also ensured with metal roofs because they are inert and do not create off-gassing or release volatile organic compounds (VOCs) during installation compared to other roofing types. A cool metal roof can help mitigate the heat island effect, thereby reducing smog and improving air quality, especially in larger cities.

For improved energy efficiency, metal offers options such as cool coatings and above-sheathing ventilation (ASV). In addition to improving air quality, the integration of a rainwater harvesting system with a cool metal roof can contribute toward improved water efficiency.

Cool roofing

Various paint finishes and coatings with specially formulated infrared reflectivity can be specified to create cool metal roofing—a solution that offers economic and environmental benefits. Coatings help to naturally cool buildings in warmer climates and temperatures, save on building operating costs, and reduce peak utility demand.

The different colour and style options offered by cool metal roofing allow it to be specified into various designs and structures. It should also be noted that metal can be used on low-slope roof applications with a slope as low as 0.25:12, and on steep-slope applications that are 2:12 or greater.

In making decisions about roofing, the specifier must first consider how the solar energy striking the roof surface will affect the performance. This issue involves three primary components of the solar energy spectrum:

- ultraviolet (UV) rays, which account for only three per cent of the total energy striking the earth’s surface;

- visible light (VIS), which is about 40 per cent of the total energy; and

- infrared (IR), which is the largest of the three at 57 per cent.

Although one cannot see the effects of IR, it is felt as heat when it strikes a surface.

Photos © Craig Van Riel. Photos courtesy Vicwest

Solar reflectance is the portion of solar radiation immediately reflected from a surface and is reported as a decimal or percentage. The reflectance from a painted metal surface depends on the colour and pigmentation used in the coating. Any energy not immediately reflected away is absorbed by the roof or wall surface, causing it to warm up. Some of this heat energy can be removed by air flowing over the surface during the day (i.e. convective cooling) and some is emitted as infrared energy into the night air (i.e. thermal emittance). Some heat can be removed from the surface through conductive heating through the roof surface.

The premise of cool roofing is to find the best combination of solar reflectance and thermal emittance to keep the surface temperature low enough to be considered ‘cool.’ The heat energy re-emitted to the night sky is measured using a term called thermal emittance and is expressed as a decimal. Materials with high thermal emittance cool down faster than those with low thermal emittance.

When applying these calculations to metal roofing, specifiers must consider whether the surface is painted or unpainted. In broad terms, unpainted or natural metal has relatively lower thermal emittance and high reflectance than coated metal.

Photo © Nancy Prince. Photo courtesy Vicwest

When a paint finish is applied through coil coating, the characteristics are dictated by the paint formula. Depending on the coating, this can increase the thermal emittance to 0.80 or more. Most pre-painted roofs are highly reflective and emissive, which significantly reduces heat gain into the building.

In specifying cool roofing, reflectance and emittance need to be carefully evaluated. For example, in a test comparison of three roof types—a white non-metal roof, a black membrane, and an unpainted metal roof—the white roof had a high solar reflectance level and high thermal emittance. The black membrane had a much lower solar reflectance but high thermal emittance, and the unpainted metal roof had high reflectance and low emittance. Of the three roof types, the black membrane results in the highest heat gain into the building. Metal roofing with a similar solar reflectance to that of the white roof would fall between the black membrane and white roof in terms of heat gain because of its lower thermal emittance.

As a guide, one can refer to a rule of thumb developed by the U.S. Lawrence Berkeley National Laboratory (LBNL) that states for every 0.01 incremental increase in roof reflectance, the surface temperature decreases by 0.59 C (1 F). For every 0.10 increase in the value of roof reflectance, the building’s annual heating/cooling costs drop approximately $0.21/m2 ($0.02/sf). Although the figures vary by location and utility rates, these guides help estimate possible options.

Photo courtesy Vicwest

Cool paint systems also provide extended performance. Roof paint finishes are usually negatively affected by heat, UV rays, and moisture. The coatings in cool roofs lower the roof’s temperature and thereby extend the life of the paint systems. The cooler surface temperatures also decrease thermal movement of the roof from expansion and contraction and, therefore, reduce wear and tear on the roof.

Colour consideration is important, especially with steep-slope roofs. New infrared reflective pigments allow darker colours to reflect more solar energy than before without any change to the system colours or costs. The same colours can now have higher reflectance when special infrared reflective pigments are added.

Roof research

Cool roofing has been the subject of many different research studies at national laboratories in the United States. One such study at ORNL compared the weathering of low- and steep-sloped metal roofs in various colours over a three-year period with other types of roof materials. From these findings, ORNL created an energy savings model that uses a black roof as the benchmark and includes variables depending on the roof type installed. This has been turned into an online calculator available for general use at www.roofcalc.com. It can help predict building cooling and heating savings based on the roof type, construction type, location, and specific climate conditions.