How tapered insulation can eliminate ponding on low-slope roofs

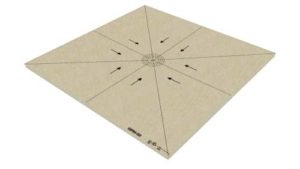

Many buildings are not designed with a straight line of drains, and benefit from a four-way tapered insulation system to move water off the roof. This approach is the most efficient way to manage roof drainage, and is recommended by industry professionals. In this scenario with a drain located in the centre, water funnels in from the higher perimeter edges on all four sides (Figure 2). Variations of two- and four-way systems exist to accommodate complexities in the field. One-directional slope and three-directional slope tapered systems can also be used to move water to gutter, drip edges, and scuppers.

Since a tapered system is more expensive than one constructed with standard flat insulation only, some might look at the former as a target for ‘value engineering.’ This can compromise the drainage intent of the design professional, architect, or roof consultant to lower the installed cost of the roof system by changing the specified slope or redesigning the configuration of the tapered panels. However, any savings upfront will certainly be lost when the roof design does not drain as it should, resulting in higher long-term costs for roof maintenance and premature roof system failure.

Most tapered insulation systems incorporate flat ISO board stock (referred to as “fill panels” or “tapered fill panels”) beneath continuing, repeating tapered panels. The tapered panels can be a single panel (or “one panel repeat”) system meaning the taper is provided by a single repeating panel in conjunction with fill panels (Figure 3). In a four-panel (or “four panel repeat”) tapered insulation system (Figure 4), the slope is developed using four repeating panels. This system utilizes 50-mm (2-in.) and 100-mm (4-in.) fill panels.

Non-typical designs can feature up to an eight-panel (or “eight panel repeat”) system with eight tapered panels making up the sloped section prior to incorporating the first fill panels. Figure 5 shows an example of four panel repeat system with a 25-mm and 50-mm fill panels and 1.5-mm per ft slope.

The various configurations, slopes, and fill panel thicknesses in ISO tapered insulation systems demonstrate its versatility to accommodate a range of roof designs and rooftop complexities.

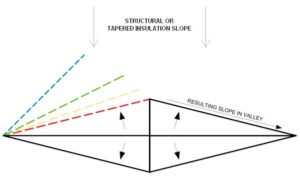

Crickets are an integral part of a tapered insulation system and are commonly used in two-way systems. Crickets can divert water toward drains and away from curbs, perimeter walls, and roof valleys. The two factors that must be considered in the design and installation of crickets are slope and configuration. The general rule of thumb is that for a full diamond cricket, the total width should be between 1/3 to 1/2 of the total length (Figure 6). The wider the design of the cricket the more slope is utilized in the field of the roof. This improves drainage efficiency. The greater the slope of the tapered insulation, the narrower the cricket can be (to a certain limit).

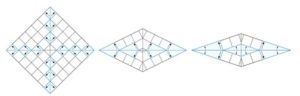

Crickets typically have diamond or half-diamond shapes (Figure 7). However, kite-shaped and snub nose crickets can also be configured to accommodate specific roof designs. To keep water from remaining on the cricket surface, the design needs to have sufficient slope (generally, twice the slope in the adjacent field of the roof). NRCA provides guidance regarding cricket geometry(Consult the National Roofing Contractors Association’s (NRCA’s) Roofing Manual: Membrane Roof Systems, 2019).

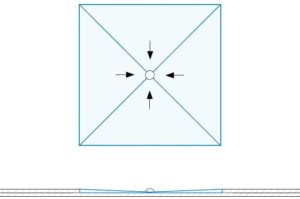

More often than not, the drains will not be located at the lowest structural points due to physical limitations (e.g. beams and columns). A proper sloped roof should have sumps at the drains to increase efficiency. Sumps can be used with both structural slope roofs and with fully tapered systems to promote positive slope to the most critical location on a roof. This helps ensure the drains are the actual low points of the roof (Figure 8).

Conclusion

Tapered insulation systems offer a cost-effective solution to achieving positive slope and improved drainage in new roof systems and roof replacement applications. Occasionally, structural slopes have limitations that can be overcome with the help of custom tapered insulation designs. They will complement each other to achieve the optimal drainage solution. An adequate rainwater management strategy that includes both proper drainage and elimination of ponding water is critical to the long-term performance and durability of a roof system. Additionally, proper design, detailing, and installation of products must be an integral part of a tapered roof system design.

Marcin Pazera, PhD, is the technical director for Polyisocyanurate Insulation Manufacturers Association (PIMA). Pazera co-ordinates all technical-related activities at PIMA and serves as the primary technical liaison to organizations involved in the development of building standards. He holds a doctorate in mechanical engineering from Syracuse University.

Marcin Pazera, PhD, is the technical director for Polyisocyanurate Insulation Manufacturers Association (PIMA). Pazera co-ordinates all technical-related activities at PIMA and serves as the primary technical liaison to organizations involved in the development of building standards. He holds a doctorate in mechanical engineering from Syracuse University.