How stone wool and Passive House are shaping a low-carbon future

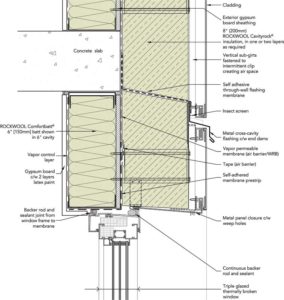

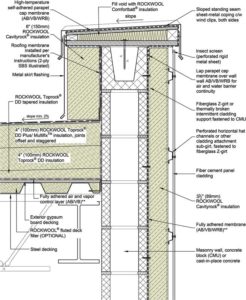

Material selection and detailing are integral for achieving Passive House performance goals. Stone wool insulation solutions are available for a wide variety of wall systems that address necessary high insulation levels along with constructability in Passive House projects. Passive House solutions and guidance for a full range of stone wool assemblies/applications as well as project-specific options are available from the manufacturer.

Since Passive House buildings are aiming for a sustainable performance and a reduction in operational carbon, opting for sustainable materials with low lifecycle impacts makes sense. Product data and transparency is increasingly important in the pursuit of low carbon buildings. This includes certification and listings, EPD, life cycle assessment (LCA), Health Product Declarations (HPDs), and voluntary participation in the Declare labelling program that promotes healthy building materials through product transparency and ingredient disclosure, including the Declare Label for Red List Approved, for example.

Low carbon insulation solutions, such as stone wool, with product-specific EPDs linked to Embodied Carbon in Construction Calculator (EC3) databases, including the PHN PHribbon, allow architects and designers to review carbon data prior to making decisions and to optimize building designs to consider total cradle-to-grave carbon emission outcomes. This can also help balance project goals—including the anticipated environmental, societal, occupant, and operational benefits—with costs.

Case study: University of Victoria student housing and dining

Architects Perkins+Will have demonstrated the significant potential of a Passive House approach extends well beyond traditional residential construction and can be scaled up to include all types and sizes of buildings. In fact, the firm states they are “committed to help bring the country’s first generation of large-scale, complex civic, institutional, and commercial Passive House buildings to life.”

This goal was achieved with the University of Victoria (UVic) student housing and dining complex. The mixed-use development spans an impressive 31,000 m2 (333,681 sf) and comprises two buildings. It seamlessly integrates 782 student residence rooms, a spacious 600-seat dining hall, as well as conference, academic, and common spaces. The buildings (officially named Čeqwәŋín ʔéʔlәŋ or Cheko’nien House and Sŋéqәʔéʔlәŋ or Sngequ House) were designed to Passive House standard and, if certified, will be among the largest Passive House buildings in Canada and the first Passive House buildings at the University of Victoria.

With super-insulated and airtight envelopes, both exceed Step 5 of the BC Energy Step Code—the highest level for efficiency in the province. The project also includes the largest commercial kitchen ever integrated into a Passive House building.

Cheko’nien House includes an electrified commercial kitchen which is six times more efficient than a conventional gas-powered commercial kitchen. This will help contribute to a reduction in GHG emissions by 80 per cent for the whole building.

The design and construction of the UVic student housing and dining project is reflective of the university’s commitment to a low carbon future as outlined in the “UVic Climate and Sustainability Action Plan 2023,”4 which aims to bolster climate action and sustainability while advancing the United Nations Sustainable Development Goals (UN SDGs).5 The new complex (Cheko’nien House and Sngequ House) represents a dramatic 90 per cent reduction in its net carbon footprint compared to the buildings they replaced.

In addition to targeting Passive House certification, the complex is also targeting LEED v4 gold. Both Cheko’nien House and Sngequ House represent best practices in energy-efficient, sustainable design, while emphasizing occupant comfort and well-being, social connection, and engagement. The project’s exterior wall system incorporates 203 mm (8 in.) of stone wool ci for a ventilated rainscreen strategy that serves a number of important functions. Key goals included:

- Radical energy efficiency.

- Extremely low operational carbon.

- Reduced GHGs.

- Superior thermal comfort and indoor environmental quality.

The institute also sought to address climate change by building for resiliency to 2050 climate projections, futureproofing in terms of performance, while endeavoring to meet the university’s climate commitments to the Clean BC Plan and those outlined in its Sustainability Action Plan. The project teams had to balance additional goals such as fire protection, moisture management, climate resilience, durability, air quality, circularity, transparency, acoustics, and more. Stone wool insulation contributed to each of the outline performance objectives.

Notes

1 See the Government of Canada – Natural Resources Canada at natural-resources.canada.ca/energy-efficiency/green-buildings/24572.

2 Refer to https://passivehousenetwork.org/phribbon.

3 For more details, see the blog by Passive House International at blog.passivehouse-international.org/summer-comfort-passive-house.

4 Visit www.uvic.ca/about-uvic/climate-sustainability-plan/index.php.

5 Consult https://sdgs.un.org/goals.

Mahnaz P. Nikbakht is the architectural specifications manager at ROCKWOOL North America and president and chairperson of the Quebec Passive House Association (Bâtiment Passif Québec). With more than 20 years in the building materials industry, Nikbakht has served as a civil engineer, technical application engineer, product manager, and sales and business development manager in Europe and North America, as well as a representative in European Committee for Standardization (CEN), International Organization for Standardization (ISO), and ASTM standardisation committees. Her expertise span from concrete and geosynthetics to drainage, waterproofing, and insulation materials. Nikbakht can be reached at mahnaz.nikbakht@rockwool.com.