Healthier Indoor Air: Reducing harmful emissions from building materials and consumer products

IAQ guidelines

Creating effective and targeted IAQ standards requires the consideration of two main elements: the use of widely accepted standardized testing methods and the availability of health-based reference values for acceptable emissions and exposure levels. To be fair and consistent to all manufacturers, emission results need to reproducible from lab to lab. This is only possible through standardized testing and test protocols, requiring specific quality assurance provisions.

Test conditions also need to resemble, as much as possible, an actual indoor environment, which means describing and standardizing test methods close to the conditions found in indoor environments, such as the amount of building material present, typical ventilation rate, temperature, and relative humidity. The comprehensively described test method must also be comprehensible to a multitude of stakeholders to ensure the test’s broad acceptance.

Equally important, the health-based reference values for chemicals of concern must be established by credible health organizations, which are responsible for the jurisdictions in question and operate in a transparent fashion. Formaldehyde was declared toxic under CEPA, as its continued and increasing use was “entering the Canadian environment in a quantity or concentration that constitutes or may constitute a danger for the environment on which life depends and a danger in Canada to human life or health.” (This information was obtained from Environment Canada and Health Canada’s 2001 Priority Substance List Assessment Report: Formaldehyde.)

Health Canada has developed Residential Indoor Air Quality Guidelines (RIAQG) for some of the VOCs most commonly found in indoor air, which can guide setting the maximum allowable concentrations indoors. For example, HC established a RIAQG for formaldehyde in 2006 based on eye irritation and respiratory symptoms. For formaldehyde, a one-hour average exposure limit is established at 123 µg/m3 or 100 parts per billion, based on eye irritation in a study performed in the United States.

An eight-hour average exposure limit has been established at 50 µg/m3 (40 ppb) that was the lower end of the exposure level associated with no significant increase of asthma hospitalization in a 2002 study. (The study in question, “Domestic Exposure to Formaldehyde Significantly Increases the Risk of Asthma in Young Children,” was published in Eur. Respir. J. by K.B. Rumchev, J.T. Spickett, M.K. Bulsara, M.R. Phillips, and S.M. Stick in 2002.) This eight-hour average exposure limit was used to assess whether the maximum allowable chamber concentrations specified in CSA O160 would ensure an indoor air concentration below the exposure limit.

Material emissions testing for VOCs

Chemical emissions from building materials are typically determined in an enclosure that is climatically controlled

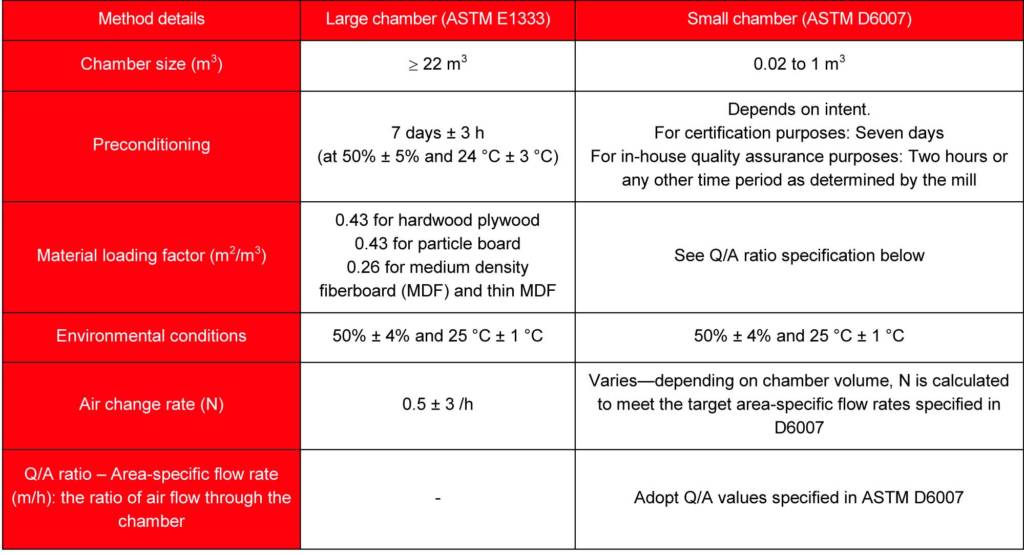

to mimic typical indoor environmental conditions. The most frequently used enclosures are ‘small-scale’ chambers with volumes of 1000 L (35 cubic ft) or below. NRC used 50-L (1.76 cubic ft) chambers (Figure 3) to characterize the emissions from composite wood products. The results were used to develop pertinent sections of CSA O160. Small-scale chambers at NRC meet the specifications given in ASTM D6007, Standard Test Method for Determining Formaldehyde Concentrations in Air from Wood Products Using a Small-scale Chamber, which is the small-scale emission test method referenced in CSA O160 and CARB ACTM 93120. The test conditions given in ASTM D6007, including temperature, humidity, air change rate, and material loading ratio, are summarized in Figure 4.