Guide to designing and installing commercial IGU glazing

Glass protection and cleaning

Since it is difficult to protect glass from damage during construction, it is important to check daily and document glazing materials if building teams need to provide evidence of post-glazing damage. In addition, a number of best practices should be followed to best protect the glazing on the jobsite.

- Paint, plaster, and sealant spills or splashes should be removed from the glass immediately.

- Protection should be provided to prevent weld splatter, sand blasting, concrete alkaline deposits, or other caustic materials from contacting glass surfaces as these materials will permanently damage glass surfaces.

- Protective coatings or release agents applied to the glass should be evaluated for compatibility to the IGU, the glazing system, and the fenestration system’s frame. Compatibility should be specified as part of the project.

- Glass surfaces should be cleaned soon after installation and on a regular basis if surrounding construction leaves deposits such as concrete runoff, rust stains, sealant bleeding, etc., on the glass.

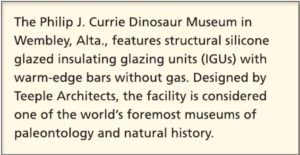

Knowing IGU glazing guidelines

IGUs can be a performance asset to a commercial project. Specifiers can refer to guidelines such as those found in IGMA TM-3000 to ensure they are making informed decisions when it comes to specifying IGUs.

1 Refer to the Fenestration and Glazing Industry Alliance (FGIA), IGMA TM-3000, North American Glazing Guidelines for Sealed Insulated Glass Units for Commercial and Residential Use.

2 Refer to AAMA/WDMA/CSA 101/I.S.2/A440-22, North American Fenestration Standard/Specification for windows, doors, and skylights (NAFS), store.fgiaonline.org/pubstore/ProductResults.asp?cat=0&src=A440-22

3 See CAN/CGSB 12.20-M89, Structural Design of Glass for Buildings, www.scc.ca/en/standardsdb/standards/4300

4 See ASTM International, E1300, Standard Practice for Determining Load Resistance of Glass in Buildings, www.astm.org/e1300-16.html.

5 See American Society of Civil Engineers/Structural Engineering Institute, ASCE/SEI 7, Minimum Design Loads and Associated Criteria for Buildings and Other Structures, ascelibrary.org/doi/book/10.1061/asce7.

6 Visit Kasian, “YVR Pier D Expansion: Creating a living legacy in airport design,” kasian.com/project/yvr-pier-d-expansion-airport-design.

7 See Teeple Architects, Philip J. Currie Dinosaur Museum, www.teeplearch.com/portfolio/philip-j-currie-dinosaur-museum/.

8 See Viracon, Architectural Glass Gallery: Plais Des Congrès Montreal Convention Center, www.viracon.com/projects/view/id/1305/.

Amy Becker is the Fenestration and Glazing Industry Alliance’s (FGIA’s) glass products specialist. She oversees the operation of the Insulating Glass Certification Council/Insulating Glass Manufacturers Association (IGCC/IGMA) and Insulating Glass Manufacturers Association of Canada (IGMAC) insulating glass certification programs, and serves as the internal auditor for FGIA fenestration certification programs. With more than 20 years of industry experience, she is also a staff liaison for glass-focused committees and task groups, and represents FGIA and its members at meetings of other industry organizations. She can be reached at abecker@FGIAonline.org.