Guide to designing and installing commercial IGU glazing

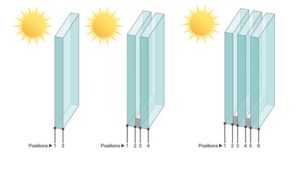

Silicone glazing sealants generally release a small amount of invisible silicone material over time. This material then migrates up to 100 mm (4 in.) or more across the #1 outer surface of the glass. This very thin layer of silicone normally only is seen by a difference in wetting action during periods of rain. That said, this film cannot be removed and will attract dirt. Consequently, dry-glazed gaskets are generally preferred for use with #1 surface coated glass.

Sealants used as heel beads or air and weather seals in contact with the IGU should have the ability to remain pliable under all expected temperatures, temperature, ultraviolet (UV) exposure, and environmental conditions as to not interfere with the movement capability of the unit, which could lead to possible glass breakage or seal failure.

Be aware that IGUs with heat-absorbing or reflective glass can reach temperatures of 60 C (140 F) or more in sunlight and still air. IGUs used in spandrel areas and vacuum insulated glazing (VIG) may become even hotter, as high as 90 C (194 F) or more. Consequently, glazing materials must be able to perform at these temperatures. With VIGs, since there is no air flow or cooling effect in the vacuum cavity, glass temperatures may exceed limits for thermal breakage. Therefore, specifiers should verify with the fabricator regarding the feasibility of the installation.

For sealants, in addition to tapes, gaskets, or fins, they must provide a weathertight seal to the glazing cavity for the life of the installation. Care should be given to these glazing materials which can experience shrinkage over time. Consequently, special installation or corner sealing treatments should be considered.

The glazing sealant manufacturer should be consulted to verify that the sealant’s life expectancy and performance is adequate installation. Information on correct application techniques or guidelines for compatibility, if required, should be requested.

In addition, the glazing sealant manufacturer should be consulted to review the sealant performance in terms of adhesion, movement capability, compatibility with IGU sealants, and adequate life expectancy for its intended end-use. It also is crucial that compatibility testing is performed for the IGU’s edge and primary sealant system with glazing sealants, setting blocks, gaskets, or other components in direct contact or close proximity. This testing will help prevent IGU seal failure and glass surface contamination.

Glazing systems

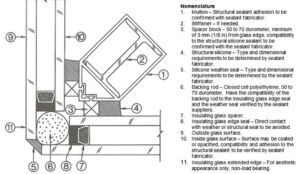

The guidelines refer to three common types of IGU glazing systems: structural glazing, butt glazing, and dry glazing.

Structural glazing or stopless glazing, where the IGU is retained only by a silicone sealant or adhesive joint, requires special care as seal failure of a unit glazed without exterior stops could lead to the exterior lite falling from the building. The following factors should be considered in the design and installation of IGUs for stopless glazing.