Grounding HVAC Motor Shafts: Protecting bearings and lowering repair costs

By Adam Willwerth, MBA

Challenged to reduce energy consumption, facility managers are installing variable frequency drives (VFDs)—also known as inverters—in building HVAC systems. By allowing motors to run at less than full speed, these drives can yield energy savings of 20 to 30 per cent, but they also induce currents that can damage bearings and shorten motor life. The resulting repair costs can diminish any savings from their use.

To make HVAC systems sustainable and energy-efficient, a reliable method of bearing protection is required. Conventional options such as insulation, spring-loaded grounding brushes, and ceramic bearings can have drawbacks. More promising are relatively new shaft-grounding rings, also called bearing protection rings.

Destroying bearings and killing motors

Many HVAC fans and pumps continuously run, but often at reduced loads. Their energy consumption correlates to their flow rate cubed, and the motors driving them will use less power if controlled by a VFD. In fact, reducing a fan’s speed by 50 per cent cuts the horsepower needed to run it by a factor of eight. In light of this, mechanisms restricting the output flow of fans or pumps can be seen as old-fashioned and wasteful.

Although the energy-saving potential of VFDs has never been disputed, the true cause of VFD-induced bearing failure has often been misdiagnosed, until recently. Eventually, repair shops and testing consultants proved high peak voltages, fast voltage rise times, non-sinusoidal shaft currents, and parasitic capacitance associated with typical pulse-width-modulated VFDs led to the cumulative erosion of bearings. Since many of today’s motors have sealed bearings to keep out dirt and other contaminants, electrical damage has become the most common cause of bearing failure in VFD-controlled air-conditioning (AC) motors.

Although the energy-saving potential of VFDs has never been disputed, the true cause of VFD-induced bearing failure has often been misdiagnosed, until recently. Eventually, repair shops and testing consultants proved high peak voltages, fast voltage rise times, non-sinusoidal shaft currents, and parasitic capacitance associated with typical pulse-width-modulated VFDs led to the cumulative erosion of bearings. Since many of today’s motors have sealed bearings to keep out dirt and other contaminants, electrical damage has become the most common cause of bearing failure in VFD-controlled air-conditioning (AC) motors.

Without mitigation, voltages repeatedly build up on the motor shaft to a certain threshold, then discharge in short bursts along the path of least resistance, which usually runs through the motor’s bearings. The discharge rate tends to increase with carrier frequency.

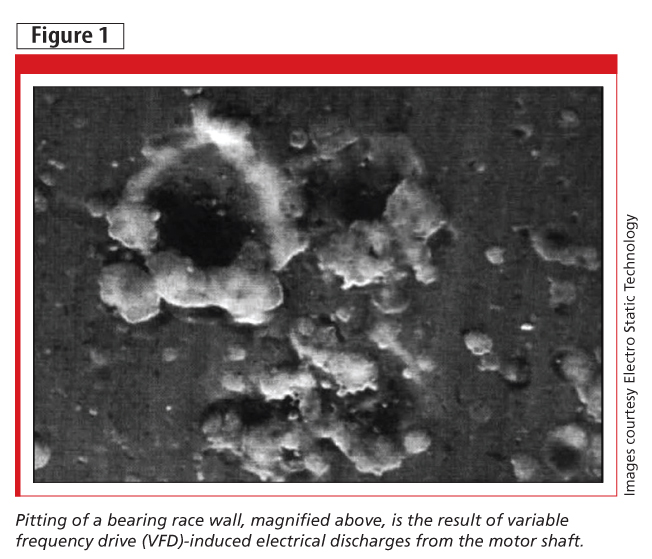

Through a process known as electrical discharge machining, these ongoing discharges cause pitting of the balls and race walls (Figure 1). In essence, these random discharges eat away the metal in the areas where they occur, damaging bearings in the same way controlled discharges eat away areas of a block of metal in electrical discharge machining, creating a desired shape part or mould. Concentrated pitting at regular intervals along the race wall can cause washboard-like ridges called fluting (Figure 2)—a source of vibration and noise that can reverberate through ductwork. By the time such damage is heard, bearing failure is often imminent.

The need for shaft grounding

The need for shaft grounding

Standards issued by the U.S. National Electrical Manufacturers Association (NEMA) highlight the need for extra bearing protection for VFD-driven motors.

NEMA MG1, Motors and Generators, Section IV, Part 31, “Definite-purpose Inverter-fed Polyphase Motors,” will be addressed by MasterFormat Division 23 05 13–Common Motor Requirements for HVAC Equipment. It recommends bearing insulation at one end of the motor if the NEMA motor frame size is 500 or larger and the peak shaft voltage is greater than 300 mV. In these larger motors, bearing damage may be due in part to magnetic dissymmetries—from using segmented stator punchings—resulting in circulating end-to-end shaft currents.

For smaller motors, the same standard recommends insulating both bearings with high-impedance insulation or installing shaft-grounding brushes to divert damaging currents around the bearings. For these motors, a VFD can generate high-frequency common-mode voltage, which shifts the three-phase winding neutral potentials significantly from ground. The damaging voltage oscillates at high frequency and is capacitively coupled to the rotor, resulting in the current path-to-ground running through either one or both bearings.

The NEMA standard is quick to point out, however, bearing insulation will not prevent damage to other connected equipment. When the path to the bearings is blocked, the damaging current seeks another path-to-ground. This is often through:

- a pump;

- gearbox;

- tachometer;

- encoder;

- break motor; or

- other piece of connected equipment that can consequently result in bearing damage of its own.

Bearing protection rings

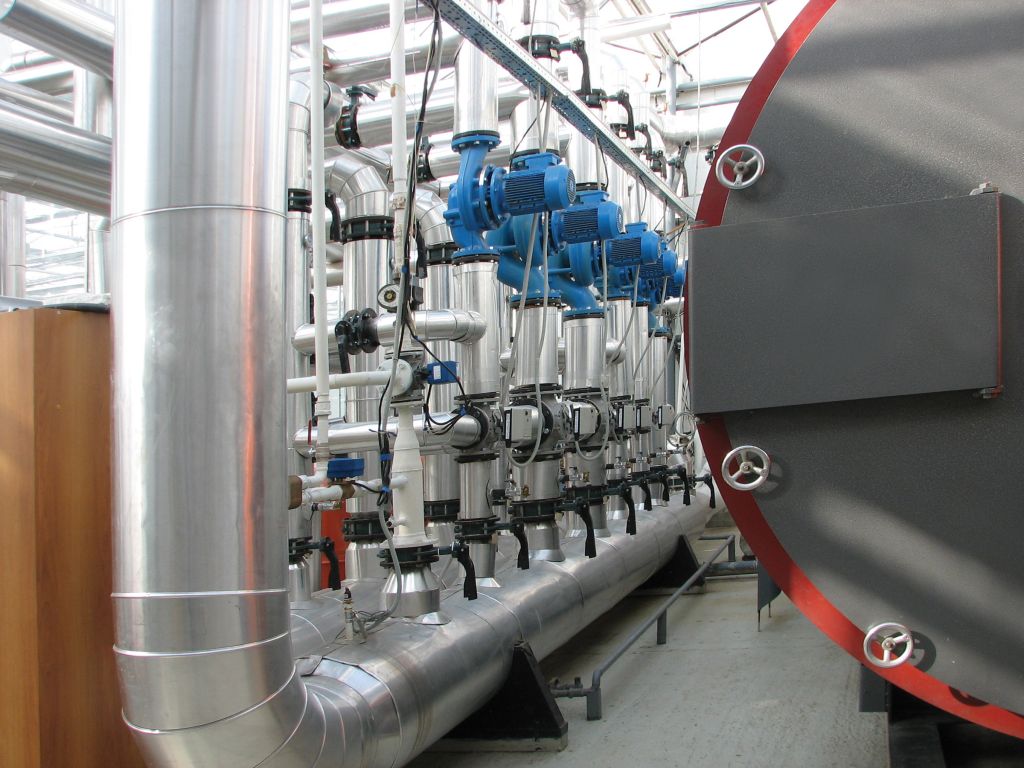

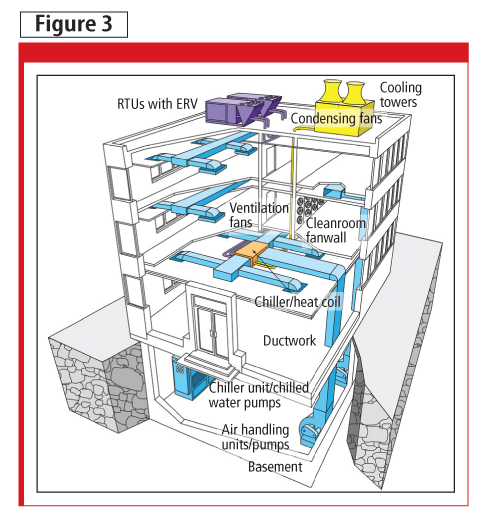

HVAC applications for bearing protection rings include:

- rooftop systems;

- indoor and outdoor air-handling units (AHUs);

- ventilation fans;

- fan walls;

- air- or water-cooled chillers;

- chilled water and other pumps;

- condensing fans; and

- compressors.

Ironically, some products designed to protect bearings from electrical damage—such as conventional spring-loaded grounding brushes—require extensive maintenance themselves. Others, such as ceramic bearings, can shift damage to connected equipment. Many so-called ‘inverter-duty’ motors offer enhanced winding insulation, which does nothing to guard against bearing damage. If they are to be truly ready for use with VFDs, these motors also need bearing protection.

One of the most promising protective devices uses the principles of electron tunnelling, field emission of electrons, and ionization to safely and efficiently bleed off damaging currents. Installed around a motor’s shaft, a bearing protection ring provides a very low-impedance path from shaft to ground, bypassing the motor’s bearings.

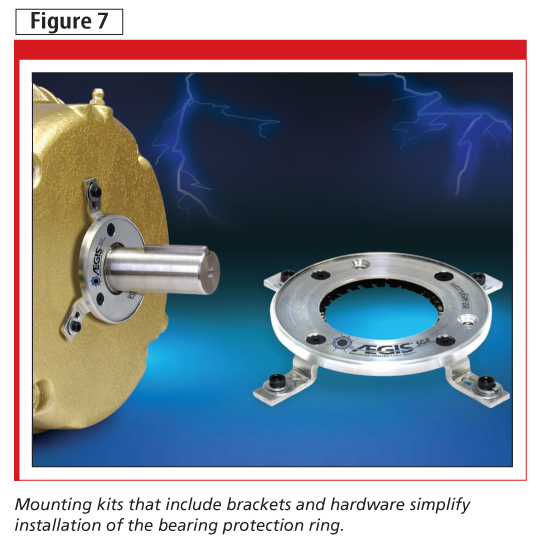

As preventive maintenance for motors already in service, rings can be quickly and easily retrofitted onto virtually any motor regardless of shaft size, horsepower, or end-bell protrusion using conductive epoxy or universal mounting kits. The most effective ring has conductive microfibres lining its entire inner circumference, completely surrounding the motor shaft. This design boosts the ring’s electron-transfer rate. Once installed, this ring requires no maintenance and lasts the motor’s life, regardless of revolutions per minute (rpm).

Shaft-grounding on rooftop units

Bearing protection ring effectiveness has been demonstrated on rooftop air-conditioning units installed on commercial buildings (Figure 4). Atop a Michigan department store, technicians took voltage readings from one of the packaged unit’s VFD-controlled HVAC motors using a voltage probe and a portable oscilloscope—both before and after installing the ring on the motor’s shaft.

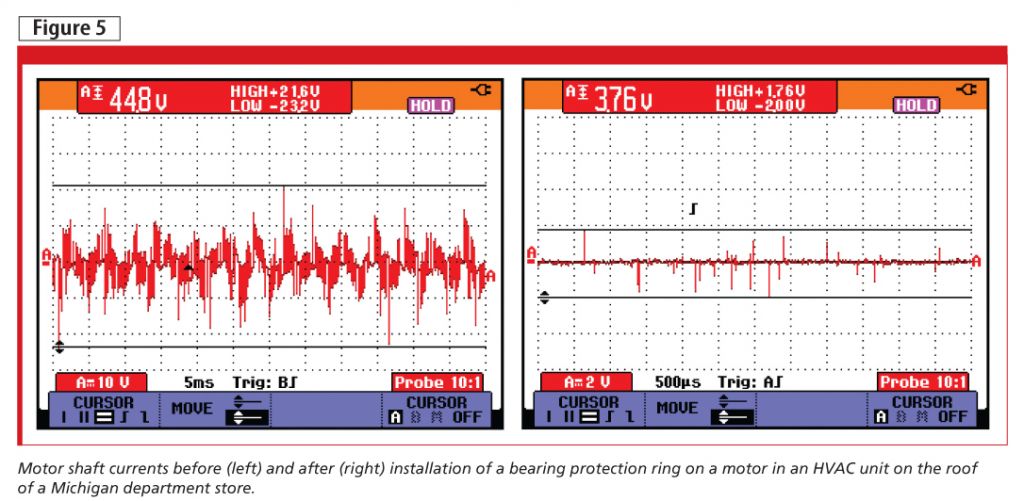

The 15-HP motor runs a belt-driven fan. In a continuous 60-msec trace with the motor running at 3600 rpm (80-Hz output), discharges from the shaft were 44.8 V peak-to-peak—high enough to cause pitting of the motor’s bearings (oscilloscope settings: 10 V/div, 5 msec/div). After the grounding ring was installed, a follow-up test at 3600 rpm showed discharges had dropped to only 3.76 V peak-to-peak (Figure 5)—well below levels that damage bearings (oscilloscope settings: 2 V/div, 500 μsec/div).

The 15-HP motor runs a belt-driven fan. In a continuous 60-msec trace with the motor running at 3600 rpm (80-Hz output), discharges from the shaft were 44.8 V peak-to-peak—high enough to cause pitting of the motor’s bearings (oscilloscope settings: 10 V/div, 5 msec/div). After the grounding ring was installed, a follow-up test at 3600 rpm showed discharges had dropped to only 3.76 V peak-to-peak (Figure 5)—well below levels that damage bearings (oscilloscope settings: 2 V/div, 500 μsec/div).

Success in hospital AHUs

Healthcare facilities have many reasons to strive for zero motor failures and 100 per cent uptime. Reliable heating and cooling are important for patient comfort, and continuous ventilation is vital for promoting sterility and limiting infections, especially in operating rooms, intensive-care units (ICUs), quarantine areas, and laboratories.

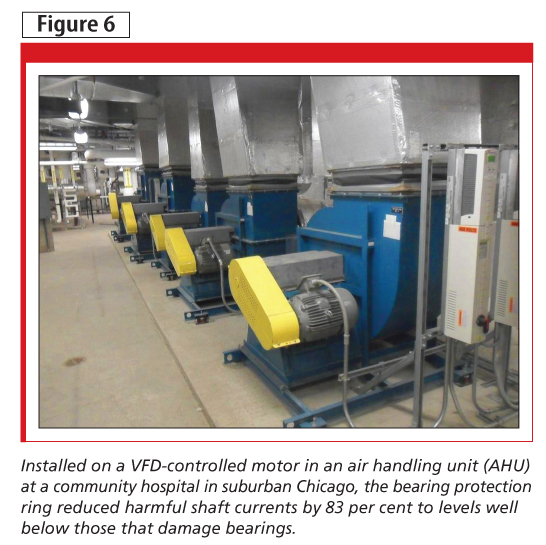

In one hospital, a motor installed in the building’s basement is a totally enclosed, fan-cooled (TEFC) unit, controlled by a 480-V VFD (60-Hz output). It runs a fan in an AHU for several operating rooms (Figure 6). Technicians first used a voltage probe and oscilloscope to confirm VFD-induced currents were indeed building up on the motor shaft and discharging through the bearings at voltage spikes high enough to cause pitting. The peak-to-peak reading was 11.4 V (oscilloscope settings: 2 V/div, 200 μsec/div). Follow-up readings after the bearing protection ring was installed showed it had lowered shaft-voltage discharges by 83 per cent.

In one hospital, a motor installed in the building’s basement is a totally enclosed, fan-cooled (TEFC) unit, controlled by a 480-V VFD (60-Hz output). It runs a fan in an AHU for several operating rooms (Figure 6). Technicians first used a voltage probe and oscilloscope to confirm VFD-induced currents were indeed building up on the motor shaft and discharging through the bearings at voltage spikes high enough to cause pitting. The peak-to-peak reading was 11.4 V (oscilloscope settings: 2 V/div, 200 μsec/div). Follow-up readings after the bearing protection ring was installed showed it had lowered shaft-voltage discharges by 83 per cent.

Since the ring was now effectively channelling harmful shaft currents away from bearings to ground, the new peak-to-peak reading was negligible (1.92 V)—too low to damage bearings (oscilloscope settings: 2 V/div, 100 μsec/div).

The hospital was advised to install bearing protection rings on all of its VFD-driven motors to prevent future bearing damage. The ring can be installed on either end of the motor, but the simplest installation is to slide the ring over the drive end and fasten it to the end bell.

While retrofits are still the most common way to protect bearings from VFD-induced shaft currents, a small number of forward-thinking original equipment manufacturers (OEMs) are now offering motors with shaft-grounding rings factory-installed.

While retrofits are still the most common way to protect bearings from VFD-induced shaft currents, a small number of forward-thinking original equipment manufacturers (OEMs) are now offering motors with shaft-grounding rings factory-installed.

These OEMs provide three-phase motors in various models with TEFC or open drip-proof (ODP) enclosures, as well as in custom designs, speeds, HP ratings, and voltage ratings.

Conclusion

For too long, the importance of shaft-grounding to protect motor bearings has been severely underestimated or completely ignored. All VFD-driven motors are vulnerable to electrical bearing damage. A savvy specifier will choose new motors equipped for use with today’s fast-switching VFDs—those with adequate protection against electrical bearing and winding damage. For motors already in service, retrofitting with an economical device such as a shaft-grounding ring is the best approach.

Operations and maintenance costs can account for 60 to 80 per cent of a facility’s lifecycle costs. When HVAC equipment does not have to be repaired or replaced as often, that percentage significantly drops. VFDs hold the promise of sizable energy savings: but without effective long-term bearing protection, this benefit could be wiped out by high maintenance costs. By diverting bearing currents safely to ground, bearing protection rings can extend motor life and ensure the reliable, long-term operation of VFD-driven motor systems, locking in energy savings to make these systems sustainable and truly ‘green.’

Adam Willwerth, MBA, is the sales and marketing manager for Electro Static Technology (EST) and has experience in industrial product development and commercialization. He is named on four patent applications pertaining to the conductive microfibre shaft-grounding ring technology, and has presented seminars on the subject of bearing current mitigation at professional conferences in the United States and Europe. Willwerth can be reached via e-mail at sales@est-aegis.com.

Adam Willwerth, MBA, is the sales and marketing manager for Electro Static Technology (EST) and has experience in industrial product development and commercialization. He is named on four patent applications pertaining to the conductive microfibre shaft-grounding ring technology, and has presented seminars on the subject of bearing current mitigation at professional conferences in the United States and Europe. Willwerth can be reached via e-mail at sales@est-aegis.com.