Going green with geothermal: What every developer needs to know

Drilling considerations

The ground’s ability to conduct and store heat does not significantly vary from site to site, but the cost of drilling can be quite different. In most cases, the depth of rock is going to be the most important geological consideration when examining the economics of a geothermal field. For example, in the Greater Toronto Area (GTA), the shallowest part of the ground is typically made up of unconsolidated clays and sands, which is easy to drill through, but is prone to collapse. This part of the well needs to be cased, counterintuitively, making the shallowest part of the hole the most expensive.

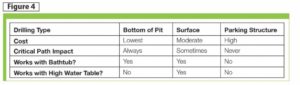

Widely speaking, there are three distinct methods of drilling and installing a borehole field under a large building (Figure 4).

Bottom of pit

Images courtesy Subterra Renewables

After the excavation is complete, drilling rigs are brought in (or craned in) to drill holes at the bottom of the pit. Although this is the least expensive form of drilling, it is often the least desirable for developers. This method is likely on the critical path, as little foundation work can move forward before the drilling and piping connections are completed. If the delay persists, the cost can be expensive when considering the time value of the money spent to excavate, and the setback in completing the project.

Surface

This method addresses the critical path impact of drilling from the bottom of the pit. Boreholes are drilled prior to excavation, and pipes are plugged and cut just below the excavation depth. After cutting, excavation can proceed unimpeded, with only minor work needed to tie in the boreholes once the excavators reach the foundation depth.

This method can often avoid many critical path delays. Since there is no need for a permit to drill a geothermal borehole, if there is a vacant site awaiting a building permit, drilling can be completed without any impact to the construction schedule.

Surface drilling is more expensive than the bottom of pit method as installers must drill through ground that will eventually be excavated. That means paying for drilling that does not result in any heating and cooling capacity, increasing costs for comparable designs.

Parking structure

Most recently, installers have been using electrically driven, low overhead drilling rigs to drill from the bottom of the parking structure in both new and existing buildings. For new buildings, excavation proceeds normally, and the piping to connect the boreholes is laid once the foundation level is reached. Boreholes are drilled after and can be delayed up until immediately prior to the plant being commissioned.

Although this is the most expensive form of drilling, the ability to delay capital spending can be worth it when considering the time value of money. Problems arise when there is a high water table or in a bathtub foundation design where the membrane cannot be perforated. In such cases, drilling from the surface can be a more effective choice.

Other opportunities

In certain cases, there may be other opportunities that can be taken advantage of when designing the system. In the same way, a heat pump system can share coincident heating and cooling loads between units, space conditioning and any other thermal loads in the building can be shared. This is especially true when it comes to a group of buildings that are cooling dominant, which is not uncommon in Canada. The heat created from these cooling loads can be used to warm domestic hot water, snowmelt systems, or even a pool. However, it is important to consider the timing of these loads. For instance, a snowmelt system is unlikely to be used in the summer when the cooling loads of the building are high.

Whatever way works best to integrate a geothermal heating cooling system into a building, it is sure to have an impact on its carbon footprint. Every project is unique and comes with certain challenges, but there is almost always an economical way to implement geothermal once all the possibilities available are explored.

Lane Theriault is the founder of Subterra Renewables, a geothermal district energy developer. He was also employed on the M&A team at Citigroup specializing in large, complex private and public market transactions. Theriault is a chartered financial analyst and received his master of business administration from the University of Toronto. He can be reached at lane@subterrarenewables.com.

Lane Theriault is the founder of Subterra Renewables, a geothermal district energy developer. He was also employed on the M&A team at Citigroup specializing in large, complex private and public market transactions. Theriault is a chartered financial analyst and received his master of business administration from the University of Toronto. He can be reached at lane@subterrarenewables.com.