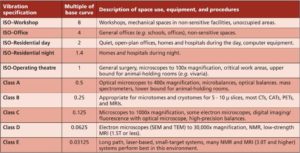

Floor vibration control strategies for adaptive reuse of buildings into labs

Changes to the existing vibration performance of the building should be anticipated when there will be significant changes to massing and partition layouts. Floor areas that previously supported heavy office furniture or filing cabinets, and were highly partitioned may be repurposed as laboratory modules with little-to-no partitioning and lower superimposed structural loads. In such cases, the floor may become livelier due to reduced mass and damping. Conversely, the introduction of partitions spanning slab-to-slab through mid-bay will generally result in lower vibration levels following reuse. These changes can be significant and may warrant additional/supplemental vibration control measures to achieve performance objectives.

Numerical finite element modelling (FEM) is a useful tool for estimating vibration performance, considering the effects of both structural and non-structural elements associated with planned reuse. The model is developed and calibrated using data which is collected during the measurement survey. The dynamic parameters that are outputs from FEM are used to generate response maps (heat maps) that illustrate the expected distribution of vibration levels on a floor. They can be an effective tool for trialing layouts and control strategies and for identifying zones of high or low vibration response.

Vibration control strategies

Controlling unwanted floor vibrations has been an increasing challenge for structural engineers, building owners, and lab operators. Traditional measures involve increasing section sizes, modifications to existing sections to improve stiffness, and increasing concrete thickness. These strategies can result in substantial material costs and added embodied carbon.

Isolation tables and platforms are very effective for controlling incoming support motions at the base of the equipment, but they are not a universal solution. They generally can only be used on the equipment for which they are designed for and can be susceptible to resonances from motions of the supporting floor. They are best suited to slab-on-grade supports or sufficiently stiff structural floors that have vibration frequencies well separated from the isolation frequency. They should not be used as a catch-all for vibration control, and mitigation measures that target the source of vibration (i.e. source isolation, location of sensitive spaces away from corridors, service spaces, and environmental sources) or the vibration path (i.e. the structural system) should be part of the solution.

Supplemental dampers – TMDs and AMDs

Supplemental dampers are devices that oppose the motion of a floor that has been excited by an externally applied force (e.g. footfalls and rhythmic activity, ground-borne vibrations). If designed and implemented properly, they achieve three goals: maintain structural motion levels below targeted criteria; optimize remedial structural measures and the number of low vibration zones; and reduce the cost of adaptive reuse due to fewer and/or smaller structural elements.

Tuned mass dampers (TMDs) are an example of passive vibration control using devices that do not require any power and are generally maintenance free for the life of the building. As the name implies, TMDs are composed of a mass supported by a spring and viscous damper that can be tuned to the specific vibration frequency of the floor. Traditionally, TMDs have been used to control perceptible and excessive motions from wind loading and crowd movement, but recent research by the authors has highlighted the viability of TMDs for use in low-vibration environments, such as labs.