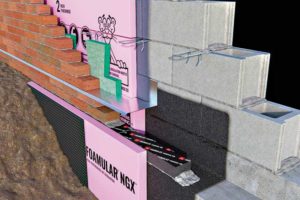

Fixing thermal bridging in masonry foundation walls

The next method, performance, may be increasing in popularity as additional strategies are employed to reduce thermal leakage throughout the assembly. In the performance method, a wall is modelled and a U-factor is calculated, referencing the overall conductivity of a wall assembly. This may take further measures, such as thermally broken fasteners, into account. Finally, compliance can be proven through a checklist software which considers performance assigned to specific assembly design types.

It should also be noted, while code compliance is the first step in addressing thermal performance, many voluntary or even compulsory codes and standards may be used to supersede or complement these requirements. These comprise standards such as ASHRAE 189.1, which includes commissioning among other criteria such as higher air leakage requirements, or the Passive house (Passivhaus) approach as a strategy to reach net-zero or net-zero-ready building performance. Passivhaus is a building standard of measures to achieve net-zero ready construction to meet carbon targets through increased energy efficiency. Specifically related to thermal bridges, this program seeks to increase occupant comfort while reducing the heating and cooling energy needed to reach these goals. Strategies include increasing air tightness and reducing heating and cooling requirements.

As these approaches are implemented, the most significant performance strategies, such as specifying ci, become a baseline for more fine-tuned approaches to managing thermal performance. Addressing details such as thermal bridging and heat recovery valves become critical to reaching the last bit of reduction in energy usage.

Insulating masonry cavity walls

The fact many insulation types may be used in masonry veneer assemblies could be one reason for the design’s continued popularity. The most common insulating material is perhaps a rigid board insulation such as extruded polystyrene (XPS), expanded polystyrene (EPS), or polyisocyanurate (polyiso). These materials come in regular dimensions and are cut to fit in the application. Joints are not necessarily required to be sealed, but simply tightly butted.

However, specifiers should verify with the manufacturer, as sealing may be required if the material is also to act as the air and weather barrier. If a material is strong enough, it may be simply compressed to fit between masonry ties attached from the veneer into the structure behind, or it may be attached using mechanical fasteners through the insulation into the structure beneath.

Adhesives may also be used with this insulation. Among other requirements, specifiers should be cautious to verify the adhesive is compatible with both insulation and surrounding materials, such as air barriers; the insulation is resistant to moisture, as the cavity will be where there is moisture present; any fire performance requirements are tested or listed; and the R-value is reliable in anticipated climate situations.

Semi-rigid mineral wool insulations have also become more common in masonry veneer wall applications. They are most likely to be secured through a compression fit between masonry ties or mechanical fasteners. Specifiers should verify moisture resistance of this special group of mineral wool, but the flexibility of the material may be advantageous for specific shapes such as curves.

Another option is spray polyurethane foam (SPF) insulation. This product is applied by combining a polyol and an isocyanate at a specific temperature direct to the substrate. Specifiers should verify moisture resistance (closed-cell versus open-cell) and climate for appropriate conditions at the jobsite and maintain the minimum cavity thickness for drainage and air circulation.