Fire and sound control for safety and well-being benefits of better acoustics

by Katie Daniel | December 7, 2017 3:41 pm

[1]

[1]By Robert (Bob) Marshall, P.Eng., BDS, LEED AP

For decades, Canadian urban development has been dominated by high-rise condo buildings, large apartment complexes, and single-family dwellings—without much in between. However, as more people move into cities and suburbs, municipal governments are facing increased pressure to contain their sprawling boundaries and provide affordable options as resources are stretched. To address this challenge, developers have increasingly turned to mid and high-rise buildings.

In the past, building codes required these structures be made of concrete and steel, but recent changes to the 2015 National Building Code of Canada (NBC) have permitted the construction of six-storey wooden structures nationwide, with plans to increase the limit to 12 storeys by 2020. With strict safety measures, Vancouver and some other jurisdictions have allowed even taller timber structures, like the 18-storey University of British Columbia (UBC) project, Brock Commons. (For more on this project, see the June 2017 Construction Canada article, “Introducing Brock Commons: Looking Up to the World’s Tallest Contemporary Wood Building,” by John Metras, Ralph Austin, and Karla Fraser. Visit www.constructioncanada.net/introducing-brock-commons-looking-up-to-the-worlds-tallest-contemporary-wood-building[2].) Indeed, in many ways, Vancouver is the Canadian leader in innovation and codes—the city also requires high levels of energy efficiency, including Passive House. (The photo above shows a six-storey wood mid-rise in Vancouver—one of the country’s largest Passive projects.)

As with all new innovations, this inevitably presents new challenges. In the case of taller wood-framed and timber structures, dealing with not only the risks of fire, but also challenges with sound transmission is essential to the health and well-being of the occupants. Planning at the concept stage and employing smarter designs can help mitigate some of the dangers of fire and/or smoke spread and excessive noise.

[3]

[3]Photo courtesy Cedaridge Services Inc.

Fire risks are a complex topic and are currently being considered by incorporating encapsulated cross-laminated timber (CLT) in preparation of the 2020 NBC. (Figure 1 shows gypsum encapsulation of CLT floors.) Generally, this requires a balanced approach, which should include early-warning systems, egress, restrictions on material flammability/combustibility, gypsum-encapsulated wood, steel compartmentation, and sprinklers.

The connection between fire protection and sound control

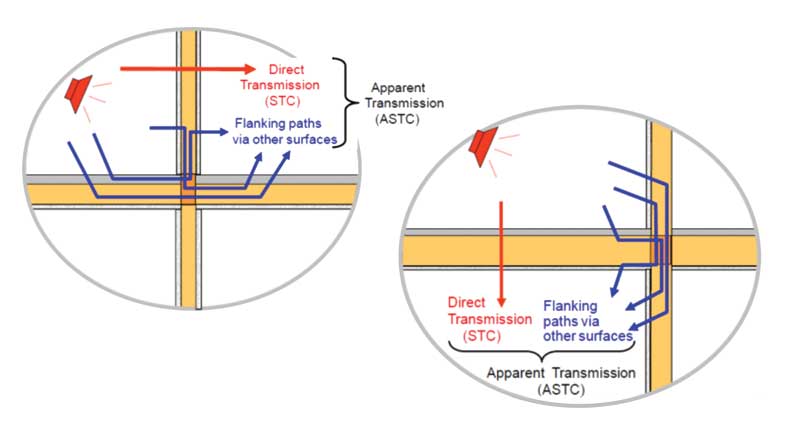

Canadians are living in closer proximity to each other than ever before. As a result, the top complaint from residents of shared buildings is noise. This challenge is often magnified in wood-framed construction where there are multiple wall and floor building connections particularly susceptible to flanking paths (Figure 2).

These flanking paths are where air—and therefore fire, smoke, and noise—can move from one unit to another through the gaps between studs, joists, drywall, ceilings, and other seams. Places where smoke and fire can more easily move through these spaces affects fire spread of the overall structure and the level of ambient noise in the building. This raises safety concerns that must be addressed by designers, authorities, and contractors.

Aside from the obvious threat of fire, a lesser-known health hazard can be found with the issue of noise. High levels of noise have been shown to cause headaches, hypertension, stress, irritability, and high blood pressure. (For more information on acoustic design in healthcare environments, visit www.cisca.org/files/public/Acoustics%20in%20Healthcare%20Environments_CISCA.pdf[4].) At work, this can lead to decreased productivity, increased sick time, and higher turnover; at home, negative impacts include sleep loss and elevated stress levels, compounding over time.

[5]

[5]Image courtesy National Research Council

The significance and potential health hazards of excessive noise have not been lost on regulators. Canada has higher code requirements for acoustics included in the 2015 NBC’s introduction of requirements for apparent sound transmission class rating (ASTC). These requirements raise sound control requirements beyond those of the traditional sound transmission class ratings (STC), which are based on the transfer of sound through walls separating two spaces. Generally speaking, the higher the number, the less sound is transmitted through the wall. These ratings are determined in a laboratory setting under controlled circumstances, which do not always translate into real-world scenarios.

Sound can travel between condo, apartment, hotel, and retirement units through ceiling spaces, demising and corridor walls, and floors. Other potential paths include pipes, electrical outlets, and other flanking paths circumventing STC-rated walls and floors. The ASTC ratings have been developed with these realities in mind; they better reflect how noise moves through these spaces horizontally, vertically, and diagonally. To meet these new requirements, which are in the process of being adopted by jurisdictions across the country, designers should look to third-party-tested assemblies for compliance and in order to reduce risks.

The specified slider does not exist.

NRC testing and ASTC ratings

The National Research Council of Canada (NRC) is the federal government’s world-renowned research organization supporting innovation, the advancement of knowledge, and technology development. It recently tested multiple configurations[6] of proprietary 15.9-mm (5/8-in.) noise-reducing, single-layer laminated drywall and noise-reducing interior stud-designed fibreglass insulation, offering 42 wood-frame and one CLT examples of ASTC- and STC-rated assemblies. Additionally, 22 steel-stud examples of ASTC- and STC-rated configurations of these materials were tested by NR[7]C[8]. All of these 65 examples received an ASTC rating of 47 or higher and STC 50, meeting or exceeding code requirements.

To comply with ASTC and STC requirements in the construction of mid-rise wood-framed and all types of high-rise structures, there are numerous options, such as assemblies employing a combination of laminated drywall, noise-proofing sealant, noise-proofing putty, and noise-reducing insulation to effectively reduce the transmission of airborne and flanking sound. For wood-stud assemblies (Figure 3), specifying such a system offers noise-reducing capabilities by dissipating sound and minimizing the transmission of noise through flanking paths to potentially achieve 54 ASTC and 54 STC ratings. For steel-stud assemblies (Figure 4), ratings of ASTC 48 and STC 50 are achievable.

With these systems, the specialized drywall means fewer layers than is required for a traditional gypsum system needed to meet ASTC standards. This results in less labour and faster construction, while also reducing material usage and reclaiming lost square footage. Further, the use of the proper noise-proofing sealants and putties help restrict the flow of air, reducing the risks of spreading fire and smoke between dwelling units.

The payoff of better acoustics and fire protection

Due to the link between the two, noise transmission is limited when the best available technology in fire prevention is used and vice versa. The myriad benefits when smart acoustic design and additional fire protection measures are incorporated in mid-rise wood-framed construction also apply to hospitals and schools.

Creating a comfortable acoustic environment in healthcare environments plays an important role in supporting safety, health, healing, and well-being for all occupants. Additionally, maintaining speech privacy in healthcare facilities helps reduce medical errors as it supports open conversations among patients. For example, Saskatoon’s Jim Pattison Children’s Hospital (Figure 5) makes use of a high-performance building envelope system along with interior acoustic assemblies for the comfort and health of patients and medical teams. Acoustic considerations include sealed electrical boxes, drywall joints, door penetrations, and floor junctions (Figure 6).

While the use of some of the necessary value-added materials may have higher initial costs, there is an overall cost savings through the recovery of usable space (Figure 7). For example, staggered stud walls are about 100 mm (4 in.) thinner than double-stud walls, thereby providing about 3.3 to 4 m2 (33 to 40 sf) of additional usable space. With approximate condo square footage costs of $500, this can be an average of $16,500 to $20,000 for an average-sized unit. (For more, see this author’s September 2016 Construction Canada article, “Implementing Smarter Sound Control Strategies.” Visit www.constructioncanada.net/implementing-smarter-sound-control-strategies[9].) The added bonuses of potentially achieving acoustic credits under programs such as the International WELL Institute and Leadership in Energy and Environmental Design (LEED) credits make this an even more attractive option. (In Part 3, “Wall Construction,” WELL provides credits for optimal performance by reducing air gaps and limiting sound transmission through properly sealing all acoustically rated partitions at the top and bottom tracks, staggering all gypsum board seams, and packing and sealing all penetrations through the wall. LEED v4 offers one or two credits in the Interior Environmental Quality [EQ] category’s Enhanced Acoustic Performance.)

As architects, engineers, legislators, building officials, and consumers look for affordable, more sustainable solutions with more healthy acoustics, but without compromising health and safety, there is no doubt mid-rise wood-stud and high-rise steel-stud construction will be increasingly popular solutions. Developers would be well-served to explore tested systems as options for commercial and residential projects and look to leading authorities such as the NRC to provide world-class research to support innovations. High-rise construction, hospitals, schools, offices, and other nonresidential projects will benefit from these additional steel-stud tested systems.

Conclusion

As more jurisdictions adopt and implement these new ASTC requirements, it has never been more important to take noise control measures into account. The additional benefits of better acoustic design add even more credence to the ASTC rating system. By making use of innovative technologies, designers/specifiers/developers can provide better fire safety and well-being for occupants and by extension, allow Canada to be a global leader in more innovative building system options.

Robert Marshall, P Eng., BDS, LEED AP, is a building science manager for CertainTeed Gypsum Canada. He has been appointed by the National Research Council (NRC) to the Standing Committee on Energy Efficiency in Buildings. Marshall can be reached via e-mail at robert.marshall@saint-gobain.com[10].

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/12/Cover-Photo.samsung-Aug2017-281.jpg

- www.constructioncanada.net/introducing-brock-commons-looking-up-to-the-worlds-tallest-contemporary-wood-building: https://www.constructioncanada.net/introducing-brock-commons-looking-up-to-the-worlds-tallest-contemporary-wood-building

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/12/Fig-1-sound.jpg

- www.cisca.org/files/public/Acoustics%20in%20Healthcare%20Environments_CISCA.pdf: http://www.cisca.org/files/public/Acoustics%20in%20Healthcare%20Environments_CISCA.pdf

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/12/Figure-2-sound.jpg

- tested multiple configurations: http://doi.org/10.4224/23001873

- tested by NR: http://doi.org/10.4224/23002223

- C: http://doi.org/10.4224/23002223

- www.constructioncanada.net/implementing-smarter-sound-control-strategies: https://www.constructioncanada.net/implementing-smarter-sound-control-strategies

- robert.marshall@saint-gobain.com: mailto:robert.marshall@saint-gobain.com

Source URL: https://www.constructioncanada.net/fire-sound-control-safety-well-benefits-better-acoustics/