Fire and sound control solutions for tall wood buildings

by nithya_caleb | July 10, 2018 12:00 am

[1]

[1]Images courtesy CertainTeed Saint-Gobain

By Robert (Bob) Marshall, P. Eng., BDS, LEED AP, and Robert Hartogsveld

It is no secret multi-unit wood buildings are growing in popularity. A March 2018 article[2] by Natural Resources Canada (NRCan) explains wood structures are easier to assemble, less noisy during the construction process, and produce less waste than other building materials. Wood structures are also not as energy consuming as other building types and create fewer pollutants over their life cycle than traditional construction materials.

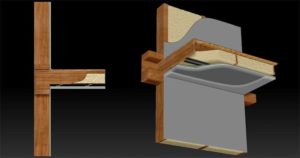

More and more Canadians are now opting for multi-unit buildings. According to the Canada Mortgage And Housing Corporation[3] (CMHC), multi-unit starts have trended higher in recent months in most major urban centres while single-detached starts have declined. Architects and builders are keen to construct wood-framed, low- and mid-rise residential structures, as they are now permitted nationally through the 2015 National Building Code of Canada (NBC) and most provincial building codes. As a result, around 500 mid-rise buildings are in various stages of design and construction across the country. With standards and regulations on the minds of architects, specifiers, and builders, new, code-tested systems to help improve living spaces should be considered (Figure 1).

[4]

[4]One of the most important changes to NBC is the mandate for improved sound control between units and for rooms one above another supported by the addition of requirements for apparent sound transmission class (ASTC) ratings. ASTC is a better descriptor than sound transmission class (STC) of how well sound, fire, and odours are actually controlled in a building as it also addresses flanking transmission paths through the many junctions at the floor, ceiling, and adjacent wall assemblies. An STC requirement of 50 is still in place in provinces in the process of adopting NBC. The ASTC rating required by codes is a minimum of 47.

A National Research Council of Canada (NRC) report[5] identifies 55 examples using gypsum board as ASTC-alternative, code-compliant solutions. This is based on the tests the agency completed. The report offers innovative alternatives to concrete toppings that can be applied to the floor of wood-framed buildings along with other materials to achieve better acoustics. The examples in the NRC document are for innovative, proprietary, noise-reducing, single-layer laminated gypsum board and noise-reducing fibreglass insulation, which together reduce noise pollution between units and adhere to 2015 NBC’s ASTC requirements. An important point for specifiers, architects, and builders is the specific assemblies and installation details in the NRC report must be adhered to without substitution in the same manner as other tested sound and fire-rated assemblies. Construction must duplicate the illustrated design and the details included in the associated text to achieve the indicated ratings. Authorities having jurisdiction (AHJ) should be consulted before installation.

There are various methods of demonstrating compliance with the new materials, including post-completion field testing or adopting the alternative code examples tested by NRC. Field testing post-construction is risky as failure to achieve the minimum sound rating may cause difficulties in obtaining an occupancy permit. To improve sound ratings to the code level, intrusive, costly corrective measures may be required, and finishes will have to be redone, not to mention likely disruptions of the living spaces.

Concrete toppings

Concrete topping is sometimes employed for sound control for rooms one above another. However, the use of wet, heavy concrete material in mid-rise, wood structures may not be the best approach due to multiple risks, including:

- the need for proper preparation;

- labour intensity;

- potential water damage;

- additional time for drying; and

- concrete cracking.

Proper preparation required

To ensure toppings do not damage the surroundings and materials susceptible to moisture, proper water dams must be installed around various fixtures, pipes, and walls for each individual project (Figure 2). This is expensive. Further, these dams are rendered useless once the project is complete as they are unique to each floor.

Labour intensive

The installation of concrete topping is also labour intensive. The cost of trucks to haul the concrete can be expensive and may require road permits for site access, potentially delaying work. Additionally, the need to access

[6]

[6]hard-to-reach floors in mid-rise, wood-framed structures without the use of a crane forces installers to spend time moving concrete in small quantities, and also increases the time required for levelling within each unit and the corridors.

Mitigating potential water damage

After the pouring process, the entire floor is inaccessible while the concrete dries. This logistical delay can cause scheduled trades people and time-sensitive work to wait. Drying of surrounding materials may also be required to mitigate potential water damage and moisture levels, thereby preventing the application of finishes. The combination of these delays can adversely impact the project’s completion date.

Concrete cracks

Another risk is concrete cracks, which can make it difficult to achieve esthetically pleasing finished surfaces (Figure 3). There is the possibility of customer complaints and expensive repairs. Moisture control is critical for proper finishing and must be managed to minimize shrinkage, especially for wood buildings. Further, there are other opportunities for concrete cracks, such as applying the overlay topping incorrectly or too thick, and differential shrinkage forces.

Mitigating the risk of sound control problems

To mitigate the above risks, one option is to consider alternative assemblies that have already been tested for sound performance. These systems may avoid application delays, as well as speed up installation, minimize complications, cut airborne noise and flanking paths, and provide fire barriers, while meeting the

code requirements for those living above and below other units.

Of the 55 tests performed by NRC, 10 of the code-alternative examples in the report involve the use of noise-reducing gypsum board and fibreglass insulation in floors without a concrete topping.

Laminated gypsum board technology paired with a noise-reducing insulation addresses direct sound transmission as well as via flanking paths. The technology is engineered using two dense gypsum board layers with a weight of ~13.7 kg/m2 (2.8 psf) and an inner layer of viscoelastic polymer acting as a shock absorber to dampen board vibrations. This option performs well acoustically over an extended range of frequencies. This results in an improved living and working space for occupants.

[7]

[7]The NRC report also provides examples of how innovative drywall and insulation technology can effectively reduce noise pollution between units while adhering to NBC’s ASTC requirements. Note some of the floors in the examples include bare subfloors, so the addition of floor finishes such as carpeting will in most cases increase the sound ratings.

Solving fire safety and sound control combination

It is also important to solve fire-safety requirements with tested assemblies in combination with sound control. With the construction of taller and taller wood buildings, fire safety and flanking sound paths through floor/ceiling assemblies have become critical (Fire and sound control solutions for wall assemblies for flanking were covered in the December 2017 issue of Construction Canada. To read, visit www.constructioncanada.net/fire-sound-control-safety-well-benefits-better-acoustics[8]).

Floor system 2, as described in the NRC report, has a fire-resistance rating of one hour as per Underwriters Laboratories of Canada (CAN/ULC) S101, Standard Methods of Fire Endurance Tests of Building Construction and Materials (For more information, visit productspec.ul.com/document.php?id=BXUV.M535[9]).

Example 52 of the NRC report was able to demonstrate how alternative code solutions with gypsum and insulation technology were able to achieve an ASTC rating of 50 or STC 50 in the absence of a concrete topping. The technologies used as well as the Type-C face layer provide a fire-rated floor without concrete.

All the examples in the NRC report are at least ASTC 47, the sound control requirement in NBC. Additional sound transmission solutions are included in NRC’s research report RR-331, “Guide to Calculating Airborne Sound Transmission in Buildings.”

Conclusion

Architects, builders, and developers of wood-framed structures can consider gypsum boards paired with noise-reducing insulation as a tested method demonstrating compliance to NBC and various provincial regulations in sound control. The tested assemblies reduce risks, prevent several problems caused by concrete toppings, and employ lightweight materials and less labour-intensive installation methods. Given many Canadians are settling in mid-rise multi-units, the NRC examples provide comfortable living space solutions.

The code changes leading to these innovations not only promote noise reduction within units, but also support safer and healthier living conditions. As a result, innovative technologies have made sound- and fire-proofing more efficient. As codes and regulations continue to evolve, the quality of innovation and products developed to adhere to these codes improve as well.

![]() [10]Robert Marshall, P Eng., BDS, LEED AP, is a building science manager for CertainTeed Saint-Gobain Canada. He has been appointed by the National Research Council (NRC) to the Standing Committee on Energy Efficiency in Buildings. Marshall can be reached via e-mail at robert.marshall@saint-gobain.com[11].

[10]Robert Marshall, P Eng., BDS, LEED AP, is a building science manager for CertainTeed Saint-Gobain Canada. He has been appointed by the National Research Council (NRC) to the Standing Committee on Energy Efficiency in Buildings. Marshall can be reached via e-mail at robert.marshall@saint-gobain.com[11].

![]() [12]Robert Hartogsveld is the architectural solutions manager for CertainTeed Gypsum, Insulation and Ceilings Ontario. He may be reached at robert.hartogsveld@saint-gobain.com[13].

[12]Robert Hartogsveld is the architectural solutions manager for CertainTeed Gypsum, Insulation and Ceilings Ontario. He may be reached at robert.hartogsveld@saint-gobain.com[13].

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2018/07/IMG_20160825_cover-touched-up.jpg

- article: http://www.nrcan.gc.ca/forests/industry/products-applications/16834

- Canada Mortgage And Housing Corporation: http://www.cmhc-schl.gc.ca/en/corp/nero/nere/2018/2018-03-08-0816.cfm

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2018/07/SFX_FLOOR_Round3_NoLogo.jpg

- report: http://nparc.nrc-cnrc.gc.ca/eng/view/object/?id=32b296e0-b437-47e8-9b8d-b487c32ae65a

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2018/07/Waterdam.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2018/07/Crack.jpg

- www.constructioncanada.net/fire-sound-control-safety-well-benefits-better-acoustics: https://www.constructioncanada.net/fire-sound-control-safety-well-benefits-better-acoustics

- productspec.ul.com/document.php?id=BXUV.M535: http://productspec.ul.com/document.php?id=BXUV.M535

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2018/07/Robert_Marshall.jpg

- robert.marshall@saint-gobain.com: mailto:robert.marshall@saint-gobain.com

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2018/07/Bob-Hartogsveld.jpg

- robert.hartogsveld@saint-gobain.com: mailto:robert.hartogsveld@saint-gobain.com

Source URL: https://www.constructioncanada.net/fire-and-sound-control-solutions-for-tall-wood-buildings/