Filling the voids: Differentiating between concrete coating and polishing

The big picture

For a concrete floor to be as maintenance-friendly as possible and retain its original appearance, it must be non-absorptive to resist moisture, dirt, and movement from volume changes. The process of curing and finishing a slab is key to constructing a dense and durable surface. A facility cannot maintain its clean and healthy status when the floor is dirty or unable to be resilient to abuse.

While each project will be unique, there is often overlap in slab requirements. Floor flatness and levelness (Ff/Fl), once only a factor in logistics and distribution facilities, has become a concern in many other sectors due to the increased use of robots. Durability remains important, as it reduces maintenance and replacement costs.

Hitting a curled joint takes its toll on both the equipment and operator. It can slow down material handling as operators reduce speed when approaching floor joints. Wear and tear at these locations is increased. This not only incurs maintenance costs, but also the finished appearances of the repairs are often inconsistent with the rest of the slab.

In the case of food facilities, a durable surface that holds up over time with minimal cracking (a larger void type in the concrete matrix) is critical, as it is less likely to create harborage for chemical, biological, physical, or allergenic contaminants. “Joint-less” slabs or those with limited shrinkage can also be helpful in this regard, as additional maintenance and work at control and cold joints is not required.

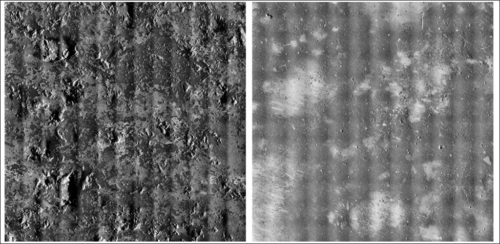

New slabs present excellent opportunities to reduce these problems and create durable surfaces that hold up over time. Allowing concrete the maximum possible amount of hydration and cure can not only help reduce undulation, shrinkage, and inconsistent Ff/Fl issues that may later create integrity issues at joints as volume change, but also in the ability of the surface to start with fewer voids, and improve the ability to resist new voids.

Internally curing with natural fibres and similar agents can decrease early autogenous shrinkage of cement paste. As with concrete polishing, nano-sized particles significantly increase reactivity and promote a degree of hydration (DOH) that decreases permeability (voids), which strengthen the entire slab, with or without joints.

“Today the use of nano-silica, high-dosed macro synthetic fibres, and other admixtures, along with advanced placing and finishing technology, is changing the entire behaviour of slabs on grade for the better,” says Jim Raffin, P.Eng., co-owner of concrete contracting firm Raffin Construction Co.

Lastly, simple, mechanical processes can also help with surface void reduction by trowel finishing with proper techniques, such as high kilopascal (kPa) blades, and ensuring that edge machines work within the same kPa parameters to avoid inconsistency with field and edge areas.

Conclusion

Performance not only varies between the two terms of coatings and polishing, but also specifically within the coating categories as well. These differences are reflected in not only final floor finish performance, but also installation methods, and certainly cost and time. Coatings cover the void-filled surface and polishing reprocesses the void-filled surface, but sometimes the answer may be to incorporate both processes for a final solution. However, relevant benchmarks must be specified to ensure proper installation.

Authors

|

Chris Bennett, CSI, iSCS, CDT, is a critical voice in the development of sustainable concrete solutions to replace expensive, outdated methods. His firm, Bennett Build, leads project teams in lowering the economic and environmental costs of designing and implementing stronger concrete systems. He can be reached at www.BennettBuild.us. |

|

Bill DuBois, AIA, CSI, CCS, is an architect with a passion for working with the entire construction project team, which includes owners, designers, constructors, and suppliers. DuBois assists in the decision-making processes necessary for efficient implementation of powerful design solutions and the creation of construction specifications. He can be reached at bill_dubois@gensler.com. |

|

John Guill, FCSI, AIA, IIBEC, SCIP, CCS, CCCA, is a registered architect, specifier, and principal at DTR Consulting. Guill has practiced architecture and engineering in a wide variety of civic, educational, and institutional projects, and helps clients develop construction specifications, identify building materials/products, and quality control to protect clients and improve projects. He has received numerous awards from CSI, the American Institute of Architects (AIA), and the Coalition for Adequate School Housing (CASH). |

|

Keith Robinson, RSW, FCSC, FCSI, is an associate at Dialog in Edmonton, Alberta. Robinson also instructs courses for the University of Alberta, acts as an advisor to several construction groups, and sits on many standards review committees for ASTM and the National Fire Protection Association (NFPA). He can be reached at krobinson@dialogdesign.ca. |

|

Rae Taylor, Ph.D., holds a doctorate in civil engineering and materials science from the University of Leeds, and a postgraduate certificate in technology management from the Open University. Her principal research interests lie in the field of materials science and improving the environmental impact of construction materials, with a focus on the effect of cement replacement materials and additives on cement microstructure. She can be reached at raemorristaylor@gmail.com. |

|

Jonathan Ware, AIA, LEED AP, LEED CxA, is senior design manager at Gray Architects and Managers. He has more than 25 years of experience as a designer and a construction project manager in the commercial industry. He is passionate about sustainable design and construction, continuous improvement, and developing individuals, teams, and relationships. Ware can be reached at jware@grayae.com. |