Far From Conventional: Metro Toronto Convention Centre’s ceiling renovation

by mdoyle | April 16, 2014 2:35 pm

[1]

[1]By Scott Debenham

When the Metro Toronto Convention Centre (MTCC)—home to events like Construct Canada and the CSC Toronto Chapter’s No Frills Tradeshow—decided to renovate its South Building, it sought replacement ceiling panels that offered both a modern look and performance. It was also important the assembly would support its pursuit of certification under Canada Green Building Council’s (CaGBC’s) Leadership in Energy and Environmental Design (LEED) rating program.

Located at 222 Bremner Boulevard in downtown Toronto, the 111,484-m2 (1.2 million-sf) MTCC South Building is the only facility in the world that has hosted both G20 and G7 Summits. It includes 34 meeting rooms and four exhibit halls with a barrier-free, fully accessible floor plan. This award-winning facility was designed by B+H Architects and opened in 1997. After 16 years, the space was in need of an update and the ceiling panels had begun to show their age.

Joshua Jaikaran, MTCC’s facilities technical co-ordinator, served as project lead and managed the South Building’s renovation from the start to completion, including the product selection. Jaikaran’s colleagues, Vlaad Zahradnik and Scot Muncaster, provided project support while sustainability officer, Vivian Fleet, managed the LEED review process.

Numerous physical characteristics were considered when choosing ceiling panels for this project:

- sizes and edge options (including metric size availability);

- indoor air quality (IAQ) impacts, such as low volatile organic compound (VOC) content;

- esthetics—a smooth, white appearance was sought;

- serviceability via a high-quality, easily cleaned surface;

- environmental characteristics to work toward LEED certification, including recycled content and high light reflectance;

- durability (i.e. lightweight, non-brittle, sag-resistant, high-performance product backed with a minimum 10-year warranty); and

- acoustics validated with a high-performance rating.

[2]

[2]MTCC was conscious of the environmental footprint of the events and meeting industry. Consequently, it offers event planners sustainable meeting solutions with options for renewable power, zero waste, locally sourced menus, and carbon offsets.

“We have had a sustainable procurement policy in place since 2008, which guides us in all purchasing practices,” says Jaikaran. “Choosing products that have recycled content and low/no-VOCs is important to the convention centre.”

To address the facility’s essential performance and sustainability goals, water-resistant stone wool ceiling panels were specified.

Sustainability of stone wool

The replacement ceiling panels for the MTCC South Building are manufactured from stone wool, a material mostly composed of basalt. The earth’s most abundant bedrock, basalt forms naturally as a by-product of volcanic activity. To create stone wool ceiling panels, manufacturers combine the basalt with recycled industrial materials, such as slag from the steel industry or recycling briquettes from other production processes. Binders, such as resins and oil, are added for rigidity and water resistance. MTCC’s stone wool ceiling panels’ faces also feature a mineral fleece with water-based paint.

Acoustic comfort

The stone wool ceiling panels used on MTCC’s South Building have a UL Classification1[3] for three acoustical categories:

- articulation class (AC), which is a measure for rating the speech privacy performance of a ceiling in an open-plan environment where the sound is reflected off the ceiling between two divided adjacent spaces (under ASTM E1111, Standard Test Method for Measuring the Inter-zone Attenuation of Open Office Components, the material’s rating is 170);

- ceiling attenuation class (CAC), which measures how much the sound pressure level changes between two rooms connected by a ceiling (under ASTM E1414, Standard Test Method for Airborne Sound Attenuation Between Rooms Sharing a Common Ceiling Plenum, the material’s rating is 22); and

- noise reduction co-efficient (NRC), which refers to a surface’s ability to reduce noise by absorbing sound and reduce sound pressure levels (under ASTM C423, Standard Test Method for Sound Absorption and Sound Absorption Coefficients by the Reverberation Room Method, the material’s rating is 0.85).

Sound absorption, as measured by NRC, is the most important category in creating comfortable spaces where occupants can hear and understand one another.

[4]

[4]Fire protection

Stone wool can withstand temperatures up to 1177 C (2150 F). It does not contribute to the development and spread of fire, giving occupants the extra minutes they may need to escape a fire.

Products are required to be tested for Surface Burning Characteristics to Underwriters Laboratories of Canada (CAN/ULC) S102, Standard Method of Test for Surface Burning Characteristics of Building Materials and Assemblies. Testing requires material to be exposed to a flame ignition source in a Steiner Tunnel Test to determine how far the fire will spread during 10 minutes, and how much smoke is developed during this period.2[5] MTCC’s new stone wool ceiling panels meet the most stringent requirements with a maximum Flame Spread Value of 5 and a maximum Smoke Development Classification of 5.

Humidity and mold resistance

Stone wool is hydrophobic, which means it neither absorbs water nor holds moisture. This makes the product ‘sag-resistant,’ even in high-humidity environments. The material is dimensionally stable and does not warp, curl, or cup. Further, its characteristics remain unaltered over time. It does not rot or corrode. Since the material is inorganic, it also does not promote the growth of mould or bacteria.

Light reflectance

Stone wool ceiling panels’ smooth surface is highly reflective; it can play a significant role in enhancing energy efficiency through better light distribution. On MTCC’s South Building, the ceiling panels have a light reflectance (LR) of 0.86. This measurement indicates 86 per cent of light—both natural daylight and illumination from high-efficiency electronic fixtures—is reflected from the panel’s surface. Maximizing the use of natural light may reduce the number of light fixtures. Lowering electronic light loads may reduce cooling costs by up to seven per cent.

The MTCC project

The products chosen for the Metro Toronto Convention Centre South Building renovation project contain up to 34 per cent recycled content. They have earned UL Environment’s Greenguard Gold Certification for low-VOC-emitting acoustic ceiling panels. Certification includes safety factors to account for sensitive individuals, such as children and the elderly, and helps ensure a product is acceptable for use in environments like schools and healthcare facilities. Choosing low-VOC products, like stone wool, can improve indoor air quality.

Excellent sound absorption was another of the MTCC’s performance criteria. As mentioned, the ceiling panels have an NRC of 0.85.

“Since we are Canada’s largest convention centre, many of our events can be quite large,” says Jaikaran, who, aside from Construct Canada, also cites the AutoShow and Fan Expo. (In 2011, the U.S. Green Building Council [USGBC] held its Greenbuild International Conference and Expo at the venue.) “We need to contain noise and provide acoustic privacy, rather than having sound penetrate the plenum and carry to adjacent spaces.”

[6]

[6]light may allow the number of light fixtures to be reduced, which lowers electronic light loads and cooling costs.

The stone wool material’s high NRC mitigates what is often referred to as the ‘cocktail effect.’ When a large group of people gathers in an open space, they escalate the volume of their voices, competing to hear one another. This makes it increasingly difficult to hear the individual conversations taking place. The ceiling panels’ high sound absorption makes it easier to hear one another without raising voices, as well as enhancing speech intelligibility to hear a speaker addressing the large group.

As part of creating comfortable, healthy spaces that respect the environment, minimizing repair and maximizing longevity are key considerations in any sustainably designed project. With renovation projects, there is a direct opportunity for comparison and improvement. Jaikaran explains MTCC’s “old tiles were brittle, dirty, broken on some edges” and showed signs of water damage and stains.

Product testing

Prior to replacing the 16-year-old ceiling panels, MTCC’s renovation project team gathered several samples to conduct its own practical experiments regarding cleaning and durability. According to Jaikaran, they wanted to ensure the panels held up to rigorous test exercises.

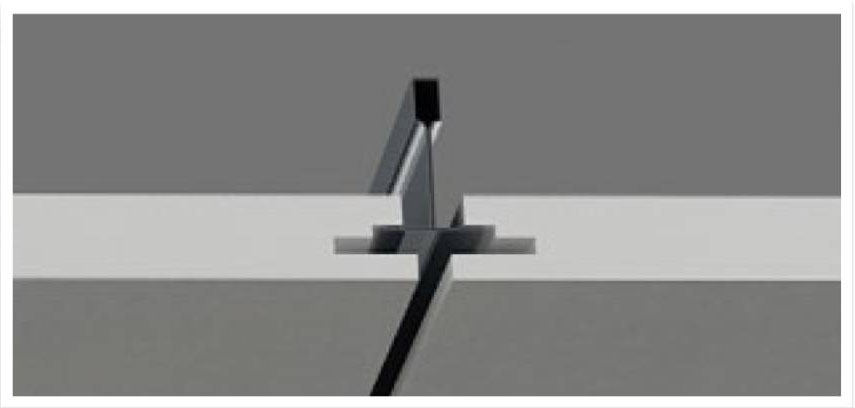

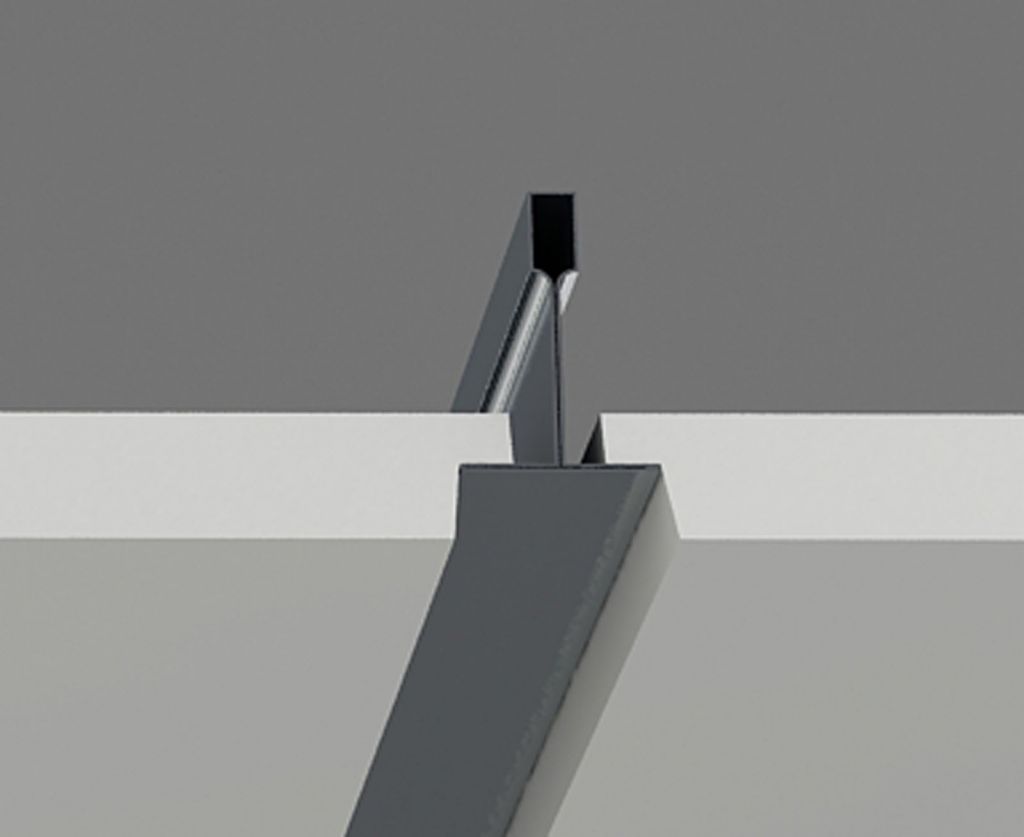

“The tiles have a tegular edge, so we were looking for how durable the tile would be with constant handling,” he explains.3[7] “Do the edges break off easily? How brittle is the tile? Do the tiles hold their texture/scrim after being handled multiple times?”

[8]

[8]Dirt or scuffs were applied to the panel samples to examine how easy the marks could be removed. The surface can be vacuum cleaned with a soft brush attachment or by using a damp cloth. The products successfully passed MTCC’s in-house tests regarding colour and texture retention. Jaikaran notes they also ensured the tiles could withstand water damage.

If a leak occurs, the ceiling panel can be easily removed for access to the plenum for repairs. As the tiles are made from water-resistant stone wool, they would not sag or warp, and do not promote growth of mould or bacteria.

Installation procedures

Even when applied in infrequently heated and unheated rooms, or at high humidity levels, stone wool ceiling panels retain their intended performance. No acclimatization is needed, which means they can be installed during the early stage of the build (when windows are not fully sealed) without any risk of deflection of the panels. Further, the tiles tend to be easily cut, simplifying labour.

Showtech Power & Lighting installed more than 3772 m2 (40,600 sf) of ceiling products in the South Building’s prefunction areas (i.e. interior gathering locations outside the main spaces where events/functions occur). The firm scheduled the facility improvements during a three-month period with activity occurring between the convention centre’s events to avoid disrupting the clients and visitors.

[9]

[9]Completed in January as a ‘zero-waste’ project, all the old ceiling tiles removed were recycled or reused.

“It’s gone well,” says Ralph Scali, Showtech’s manager. “It makes a huge difference once the new tiles are in—it certainly brightens it up.”

Conclusion

Combining energy-efficient daylighting designs with stone wool’s natural and recycled composition, durability, and performance contribute to achieving Metro Toronto Convention Centre’s sustainability goals and to meeting the project’s LEED criteria.

In one year alone, conventions and trade shows held at the facility have generated a direct-spending economic impact of $523.7 million dollars to the community. This influx of funds into the city translates into 6000 jobs, with total generated taxes estimated to be $177.5 million dollars. In terms of not only esthetics and performance, but also sustainability, the success of the South Building’s renovation and ceiling installation are important.

[10]

[10]appearance. Some standard stone wool panels have a square

edge and are easily demountable.

Recognizing MTCC’s economic impact and exceptional facilities and services, its sustainability efforts have been honored by the Tourism Industry Association of Ontario’s Sustainable Tourism Award, and the Environmental Commissioner of Ontario. Most recently, it became the country’s first conference venue to be awarded the APEX/ASTM Environmentally Sustainable Event Standard for Meeting Venue, as well as several awards and certifications from the Building Owners and Managers Association (BOMA) of Canada such as Go Green, Building of the Year, and Building Environmental Standards Level 3 Certification for Energy and Environmental Management.

Notes

1 Once known as ‘Underwriters Laboratories,’ UL is a global safety science company in testing, inspection, certification, auditing, and validation. (back to top[11])

2 Developed by Al Steiner of UL, the test has been incorporated as a reference into North American standards for materials testing. The progress of the flame front across the test material is measured by visual observation, while the smoke emitted from the end of the test assembly is measured in terms of optical density. A flame spread index (FSI) and a smoke-developed index are calculated from these results; both use an arbitrary scale in which asbestos-cement board has a value of ‘0,’ and red oak wood ‘100.’ (back to top[12])

3 Tegular-edge tiles hang on a visible and recessed grid, which creates a shadow between them, yielding a distinctive appearance. (back to top[13])

[14]Scott Debenham is Rockfon/Chicago Metallic’s district manager for Ontario/Western Canada. With more than 10 years in the building industry, he specializes in integrated ceiling solutions that provide better, safer indoor environments. Debenham has a deep knowledge of stone wool products and ceiling products that add value to buildings’ esthetic qualities and functional characteristics, while improving the performance of the spaces they cover. Along with his industry expertise, Debenham studied architectural technology and construction management at Mohawk College in Hamilton. He can be contacted at scott.debenham@rockfon.com[15].

[14]Scott Debenham is Rockfon/Chicago Metallic’s district manager for Ontario/Western Canada. With more than 10 years in the building industry, he specializes in integrated ceiling solutions that provide better, safer indoor environments. Debenham has a deep knowledge of stone wool products and ceiling products that add value to buildings’ esthetic qualities and functional characteristics, while improving the performance of the spaces they cover. Along with his industry expertise, Debenham studied architectural technology and construction management at Mohawk College in Hamilton. He can be contacted at scott.debenham@rockfon.com[15].

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2014/05/8543_005.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2014/05/8543_113.jpg

- 1: #note1

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2014/05/8543_032.jpg

- 2: #note2

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2014/05/8543_077.jpg

- 3: #note3

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2014/05/Square-Lay-In-Edge.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2014/04/Semi-Concealed-Edge2.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2014/05/Tegular-Edge.jpg

- top: #note4

- top: #note5

- top: #note6

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2014/05/Author.jpg

- scott.debenham@rockfon.com: mailto:%20scott.debenham@rockfon.com

Source URL: https://www.constructioncanada.net/far-from-conventional-metro-toronto-convention-centres-ceiling-renovation/