Façades for the future

Images courtesy Engineered Assemblies

Rear-ventilated rainscreens

Rear-ventilated rainscreen (RVRS) systems embrace continuous insulation (ci). Moisture is never welcome in the building envelope, nor in most aspects of the structure. An ideal system substructure is thermally broken, is a rear-ventilated rainscreen, and is covered with sustainable materials. A good ventilated façade can be at least 35 mm (1 3/8 in.) deep with the potential of adding an outboard insulated system in a thermally-broken substructure giving good effective R-values and protecting everything behind the weather membrane.

RVRS systems are subject to the European Deutsches Institut für Normung (DIN) standard 18516, Cladding for external walls, ventilated at rear. This standard applies to rear-ventilated cladding for façades without background, including anchoring, connection, and fixings. It specifies calculation, design, and construction principles for permanent structures.

Microclimate for balance

A building envelope plays an important role as the leading edge of a structure. Its purpose is the protection of the superstructure/core. Notably, ventilation is a vital part of the building envelope. Gravity alone will not remove moisture. The rainscreen does not propose to prevent any and all moisture from entering the façade, but gives it a front and back door from which to exit. This exit is part of the active plenum created in a true RVRS system. Air continuously flows through the system working to dry out the RVRS. This is a simplified explanation of a complex process.

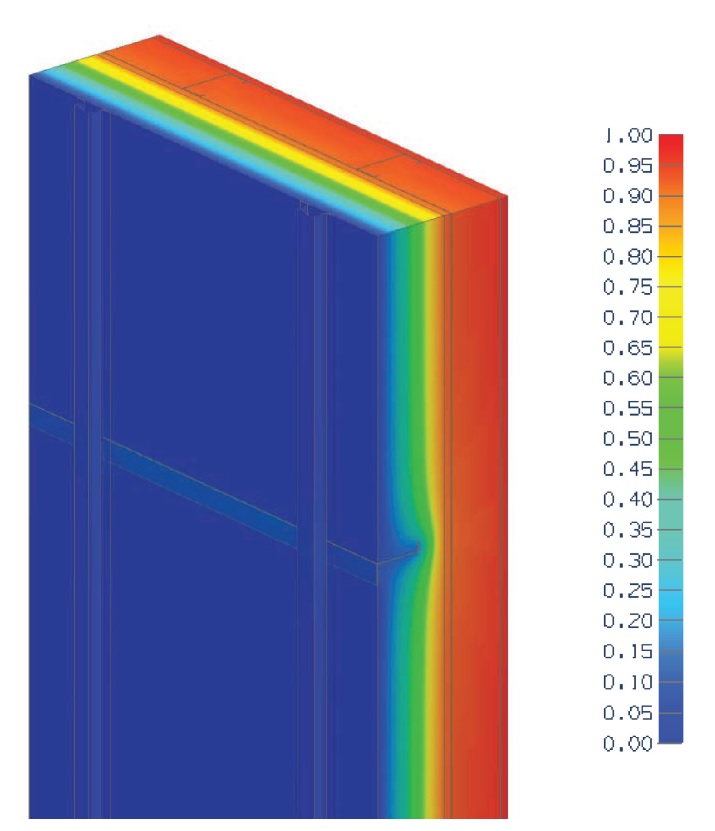

The active plenum within a substructure behind a façade is referred to as a “microclimate,” since its small climate is completely independent from the inside of the building, the rest of the envelope, and the outside. Consider a hot, sunny day in July, when temperatures outside are 28 C (82 F) or greater, and one wants to maintain a much lower temperature inside for comfort. The exterior panels essentially act as shades, in layperson’s terms. Rather than the sun beating down onto the panels and conducting heat to everything attached to them, which causes heat to be pushed through and inside the building, the microclimate moves air, hot air in this case.

Moving air dissipates the heat off the front panel, serving a purpose for the envelope in terms of heat exhaustion, and also for the panel in terms of dissipating heat for stability. If the ventilation was not properly set up, there would be a buildup of condensation, which, combined with solar heat gain, would create a virtual sauna. Imagine what such excessive, moist heat behind a panel system would do.

The active plenum exists to keep things dry, and to balance temperature and integrity. Canadian engineering firm Morrison Hershfield found having 25 mm of air space in the active plenum could produce up to 0.7 additional R-value. (For more information, see Morrison Hershfield, Thermal Performance of EAi Thermal Clips, March 22/2012, report#5123226.00.) Attaching an insulation value to the plenum is important, as it supports the idea the system strength as a whole can be more valuable than the individual components.

Some façade systems are holistic; like a high performance RVRS, everything works in a particular relationship with the other components to provide higher overall performance. In this author’s view, this is the performance the industry must move towards, leaving the old ways behind because they do not work well enough. Looking ahead to changing building codes, it is clear standards are getting tougher and both manufacturers and designers must rise to higher levels of performance.