Evolution in sprayed polyurethane foam

Fire performance

Poor fire performance is one of the most common marketed misconceptions of SPF. This is not to say foam does not have the potential to char and burn, but that it poses less of a risk than perceived. Marketing strategies can effectively play on the emotions of the reader to sway him or her toward a specific message, but design professionals should base decisions on building science—technical data, research, and an understanding of physics—rather than on sales strategies.

SPF is a foam plastic, meaning it has the potential to char and burn under certain conditions. However, just because SPF is installed in a building enclosure or separator, that does not mean disaster will follow. Many factors have to align to cause a fire—in reality, most fires that take place in Canada occur when the building is occupied, not when it is under construction. Fires do happen in buildings, mostly from cooking, but those caused by foam insulation only comprise a fraction of the total percentage. (“Fire Losses in Canada,” a September 2011 report by Mahendra Wijayasinghe, PhD, is available at www.ccfmfc.ca/pdfs/report_e_07.pdf.)

An article written by Aaron Seward, on the other hand, states: “Water intrusion makes up more than 70 per cent of the construction litigation.” (Read Seward’s June 2011 article, “When It Leaks It Pours.”) If this is so, then to a building science practitioner, it makes more sense to focus on mitigating moisture issues in buildings than fire during construction. Water intrusion may not look as dramatic as a building burning at night, but obtaining remediation for it in court can be.

Images courtesy Rockford Boyer

Building codes dictate where and when SPF can be used and applied. Therefore, following building code guidelines will reduce the risk even further. In addition to using code requirements to protect SPF from potential fire issues, the foam plastic industry has taken further steps in developing insulation products that achieve the same goal. Such products can have a global warming potential (GWP) of 1—considered non-flammable by ASTM E-681, Standard Test Method for Concentration Limits of Flammability of Chemicals (Vapours and Gasses). (For more information, read “Understanding Global Warming Potentials.”) This non-flammable liquid blowing agent can drastically reduce the flame spread and smoke development of SPF.

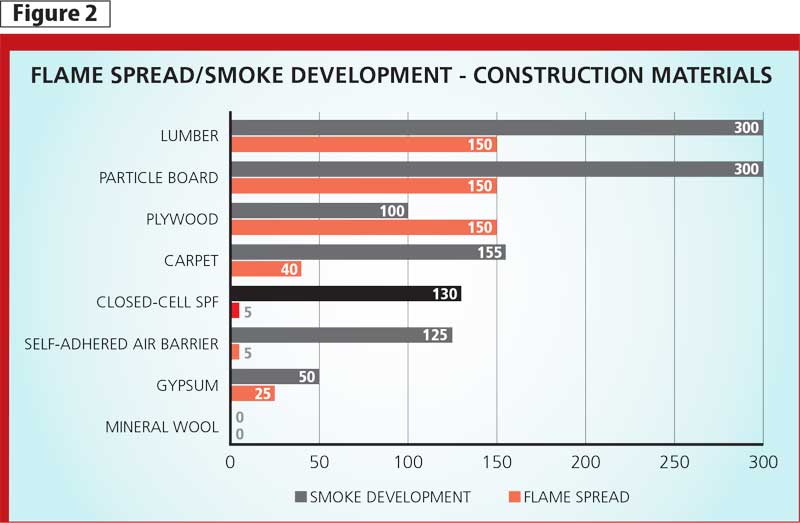

Another example has a flame spread rating of 5 and a smoke development rating of 130, while the code allows for 500 in each category. Special coatings like intumescent paints can also be applied to the SPF insulation to ensure thermal barrier and ignition barrier requirements in the building code are met. Figure 2 features a chart showing the flame spread and smoke development of typical construction materials.

Environmental considerations

Some people believe chemicals or materials manufactured from chemicals are bad for the environment or the occupants that encounter the material. This is just not the case—some SPF insulations are quite safe for both the occupant and the environment. Chemical compounds and formulations for the manufacturing of SPF insulation have significantly advanced environmentally over the past few years. Some SPF foams have been tested to GreenGuard Gold, one of the most stringent standards for indoor air quality (IAQ) of building materials.

Environmental performance considerations to make with SPF include:

- GWP of blowing agents;

- carbon creation due to manufacturing, transportation, and packaging; and

- impact on IAQ.

GWP

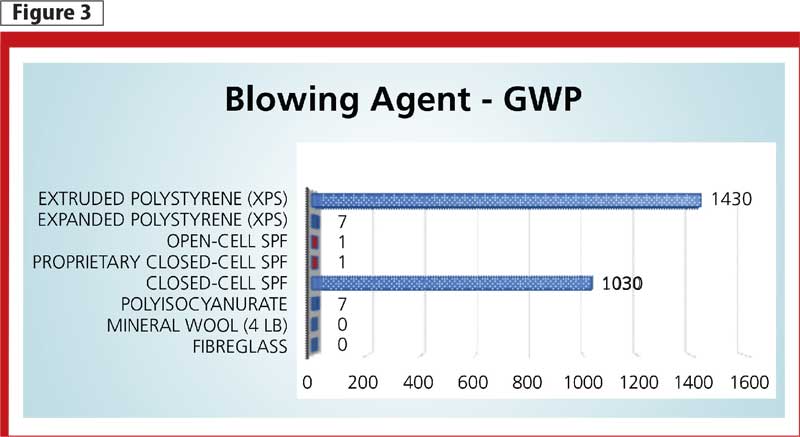

GWP is one of the most contested environmental issues with any type of insulation on the market. As foam insulation employs blowing agents to install/manufacture the material and ensure its high R-value performance, its environmental contribution can be quite significant. Various blowing agents used in the manufacture of foam products affect the environment, depending on their GWP. Lower GWP will result in less global warming, due to the heat being allowed to escape back out of the atmosphere.

In 2020, the Canadian government will ban the use of blowing agents with high GWP, so all SPF manufacturers will need to reformulate their products. Several progressive SPF manufacturers have already utilized ultra-low-GWP blowing agents successfully for several years. Water-blown-based SPFs are also readily available that boast a GWP of 1. Figure 3 shows typical insulation products with GWPs.