Evolution in sprayed polyurethane foam

Sprayed polyurethane foam

To manufacture or install SPF onsite, a trained and third-party-approved installer accurately mixes what the industry calls a ‘set,’ with a Part A and a Part B. The A-side is the isocyanurate (polyiso) portion of the set, and the B-side is the resin portion. When SPF manufacturers discuss the manufacturing processes, they are referring to the B-side or resin side of the foam set, as the A-side is typically purchased from a third-party supplier.

Manufacturing the resin starts when a recipe of precisely weighted chemicals are batched together in a reactor and continuously mixed until the formulation is equally blended. After the resin has been thoroughly mixed, it is placed into 189-L (50-gal) drums or in bulk tanks, ready to be shipped. On the jobsite, the trained installer uses a mobile spray apparatus that equally mixes the A- and B-side of the foam set and, under pressure, sprays the two components from a spray gun, where the components are mixed and reacted. The mixed liquid hits the substrates and creates a reaction that manufactures the foam, expanding to 20 to 30 times its original volume.

If a surface is acceptable for paint, it is also acceptable for SPF. If there is too much moisture on the substrate, however, this can potentially lead to improper curing.

Image courtesy RDH

Performance characteristics

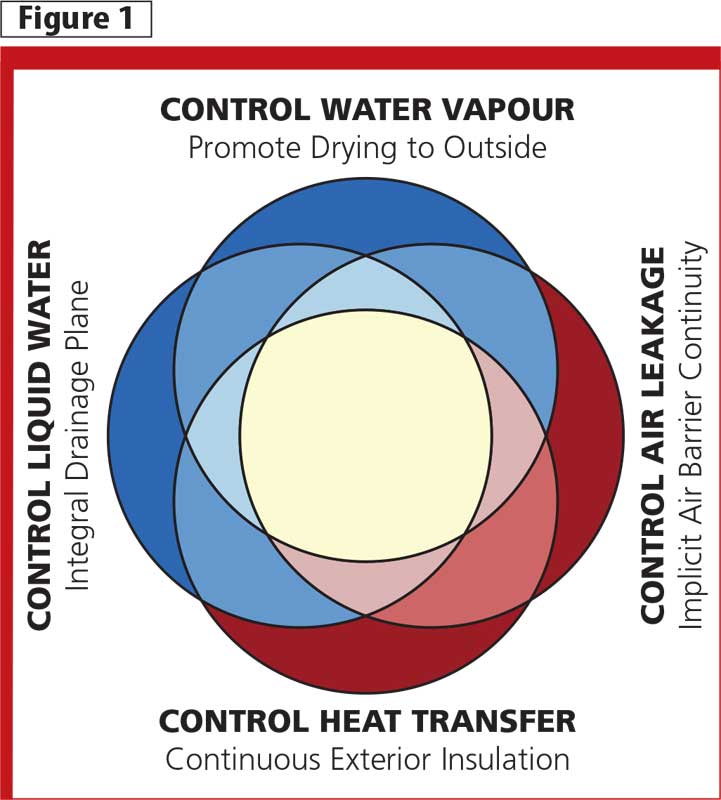

Much of the construction industry lumps all insulation products together, making general comparisons between SPF, foam board stock, mineral fibre, and other materials. These comparisons are typically related to characteristics such as R-value, moisture absorption, and acoustical properties—however, not all insulations are created equal. Some are just insulation products, while others are insulation systems controlling additional functions such as air, vapour, and water. The construction industry is moving toward a system approach to enclosure design, so when comparing insulation options, the absolute performance and functions of the system should be identified.

To ensure enclosure functionality and durability, four control layers (thermal, moisture, air, and vapour) should be considered, as they are crucial to the assembly’s overall effectiveness (Figure 1). At the product scale, MW can manage thermal and vapour control, but not moisture and air control. Utilizing a weather-resistive barrier (WRB) membrane behind the MW, however, can ensure all four control layers are covered. Foam board stock also typically needs a membrane behind the insulation, unless tape or flashing is used to create a face-sealed system. However, even with a face-sealed system, three of the four control layers—thermal, moisture, and air—would be managed.

Similarly, typical closed-cell SPF installed in a split insulation system can provide thermal, moisture, and air management; installed in an all-outboard approach, it will effectively meet the four-control-layer solution. Installing a medium-density, open-cell SPF insulation in a split insulation system can also manage all four control layers.

Building science has pushed the industry further ahead by utilizing various materials and practices to obtain high performance in buildings, so it is critical when designing an assembly to review the system performance of materials rather than just looking at individual key performance criteria.