Enabling faster returns to service when installing flooring

Returning to service faster

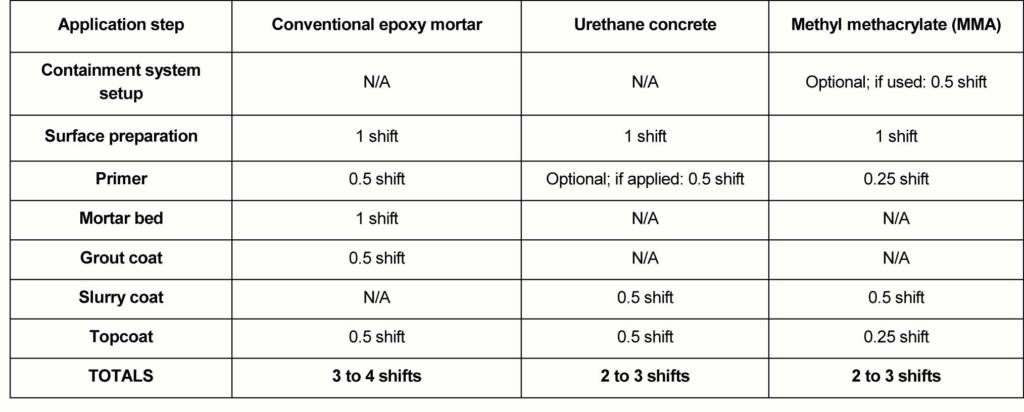

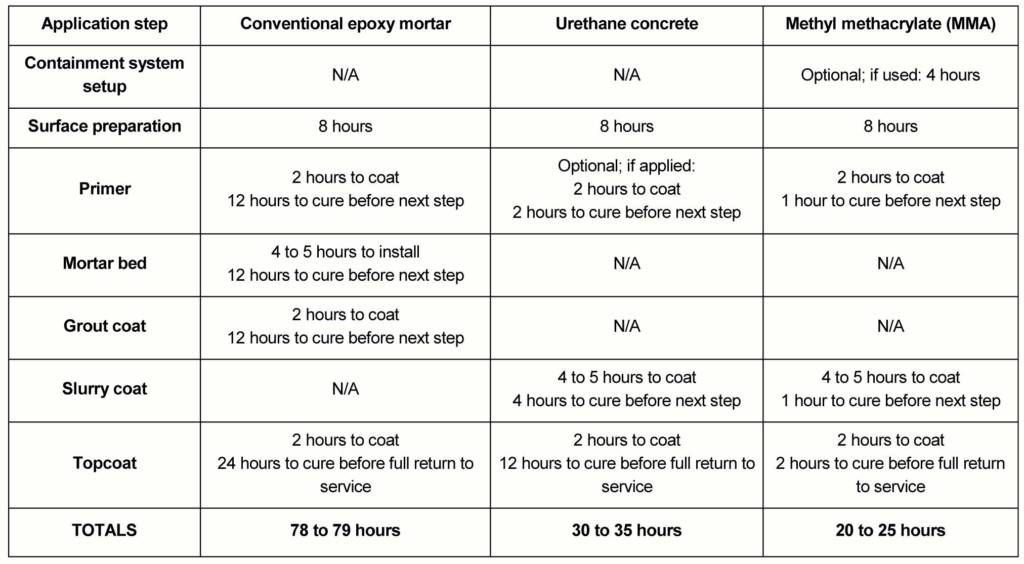

Adding up the labour steps and overall curing times of the three systems as shown in Figures 2 and 3 illustrates the efficiencies gained by selecting either a urethane or MMA flooring system. To install the 500-m2 cafeteria floor using a conventional epoxy system, it could take up to three to four crew shifts and 78 to 79 total hours, including both application and curing times. For the urethane system, the totals drop to just two to three shifts and 30 to 35 total hours, depending on the use of an optional primer and the efficiency of applying the slurry coat. The MMA system application will also take about two to three shifts and about 20 to 25 total hours, with the 25-hour total being more likely due to the probable need to set up and tear down an odour-containment system.

These approximate totals represent the complete flooring installation time that could be realized if crews were to complete all steps continuously. More realistically, installers would not run around-the-clock shifts. Assuming one eight-hour shift per day, the required steps and curing wait times could push a conventional epoxy installation up to four days, while the urethane and MMA system installations may only take as little two days.

Making a flooring choice

Faster flooring installations offer the potential to accelerate the entire construction or renovation process for a commercial facility. Any efficiencies gained during the installation can enable work to resume sooner, equipment to be placed more quickly, and the facility to ultimately return to service faster.

As established, both urethane concrete and MMA flooring applications can be completed much sooner than an epoxy mortar flooring installation, removing considerable downtime from a project. Urethane and MMA systems reduce installation steps, application times, and curing times compared to epoxies. The former system type enables the fastest installation over green concrete, making it a preferred option when project timelines cannot support a 28-day wait for concrete MVEs to dissipate. MMA systems offer the fastest actual installation potential, yet their odour often requires the added setup of a containment system.

Epoxies are still a smart choice for projects in which the installation time will not disrupt owners’ schedules. Additionally, they are viable options for areas that need to be resloped or completely resurfaced. From a longevity perspective, urethane systems have better resistance to thermal shock and chemicals compared to MMA and epoxy systems, potentially extending maintenance intervals for reduced future downtime.

Ultimately, each flooring system decision hinges on the right combination of installation and curing times in conjunction with the project timeline, budget, and longevity conditions. Success can be achieved with any system, but the best option for the project can be chosen based on the parameters described in this article.

Casey Ball is regional market segment director of flooring for Sherwin-Williams Protective & Marine Coatings. He previously served as a project development manager, drawing on his experience as a corrosion specification specialist and a technical service representative for Sherwin-Williams after starting his career as a lab technician at General Polymers. Ball has specialized in the flooring and coatings market for 15 years. He is a NACE-certified coatings inspector and a Society for Protective Coatings (SSPC)-certified concrete coatings inspector. Ball can be reached via e-mail at casey.a.ball@sherwin.com.