EIFS and thermal bridging

by Elaina Adams | January 1, 2013 9:02 am

[1]A study by Pennsylvania Housing Research Center (PHRC) showed significant reductions in centre-of-cavity R-value for steel-framed wall assemblies, reducing it by as much as 56 per cent when a framing factor (i.e. thermal bridging) was taken into account to measure R-value. (See Robert Bombino and Eric Burnett’s Design Issues with Steel-stud-framed Wall Systems [PHRC Research Report Series 58, May 1999]). The only practical way to negate the effects of thermal bridging caused by steel studs is to place insulation outboard the studs—something that can be accomplished with exterior insulation and finish systems (EIFS).

[1]A study by Pennsylvania Housing Research Center (PHRC) showed significant reductions in centre-of-cavity R-value for steel-framed wall assemblies, reducing it by as much as 56 per cent when a framing factor (i.e. thermal bridging) was taken into account to measure R-value. (See Robert Bombino and Eric Burnett’s Design Issues with Steel-stud-framed Wall Systems [PHRC Research Report Series 58, May 1999]). The only practical way to negate the effects of thermal bridging caused by steel studs is to place insulation outboard the studs—something that can be accomplished with exterior insulation and finish systems (EIFS).

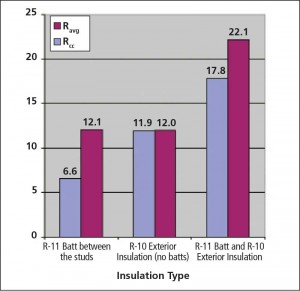

For example, an R-11 (1.94 k•m2/W) batt-insulated steel frame wall assembly is effectively R-6.6 (1.16 k•m2/W) (Ravg), a 45 percent reduction in the centre-of-cavity R-value (Rcc) which results in only a 55 per cent thermal efficiency (Ravg/Rcc). Yet, when the same assembly has the batt insulation removed and R-10 (1.76 k•m2/W) exterior insulation added (slightly more than 64 mm [2.5 in.] of expanded polystyrene [EPS] insulation), the effective R-value is almost equivalent to the centre-of-cavity R-value of the batt-insulated assembly, and the thermal efficiency is 99 per cent. When batt insulation and exterior insulation are combined, the effective R-value of 17.8 (3.13 k•m2/W) and thermal efficiency of 81 per cent are significant performance improvements to the assembly with only batt insulation. The improvement in effective R-value performance through the use of exterior insulation is clearly demonstrated in the graph on the right.

For more on EIFS and sustainable design, click here[2].

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2015/11/EifsThermal-figure.jpg

- here: https://www.constructioncanada.net/eifs-and-sustainable-design/

Source URL: https://www.constructioncanada.net/eifs-and-thermal-bridging/