Door and dock accessories increase plant safety

Be able to “see” through a door

Photo courtesy Rite-Hite

A pairing of LED and motion sensor technology allows workers to “see” what is on the other side of a door. This system alerts workers on one side of the door if something is approaching from the opposite side, thereby preventing a host of potential accidents, ranging from damaged equipment to a forklift/worker collision.

This light communication system uses the same type of motion sensors high-speed doors employ for opening and closing. Once these motion sensors detect a person or forklift approaching, flashing red LED light strips on the opposite side of the door alert personnel that someone or something is moving on the opposite side of the door. These LED alert strips can be placed on the outer portion of the door or wherever they are most easily viewed by workers.

In addition to high-speed doors, this virtual vision light communication system can be used in other applications where blind corners exist, such as hazardous intersections, aisle ends, or anywhere else in a facility with less-than-ideal vision.

Light communication improves loading dock safety

Photo courtesy Rite-Hite

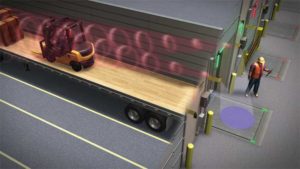

There have also been several recent advances in light-based communications systems for loading dock areas.

For safety inside the dock, a new motion sensor-based system projects a bright blue light onto the dock leveller when it detects movement inside a trailer, alerting workers near the dock opening a forklift or pallet jack could be backing out at any moment. Additionally, the system will alert forklift drivers (or workers on foot) if they are entering an unsecured trailer, by means of an audible alarm and flickering light. It also simultaneously changes the external light to red, warning the truck driver there is activity inside the trailer and it is not safe to pull away.

By providing pedestrians with additional warning time, this projection system works as a complement to the blue safety lights on forklifts. It can be added to almost any dock as an aftermarket item, and can be integrated with advanced control boxes to prevent unlocking of the vehicle restraint until activity in the trailer stops, ensuring the truck cannot pull away with a forklift operator still inside.

A similar system has been developed to increase the safety of workers outside, on the dock approach. This system uses a motion sensor mounted above the dock door exterior to detect a tractor-trailer backing into a dock position. The backing movement of the trailer triggers a visual and audible alarm.

This multisensory alert system is particularly important because collisions on the outside of the dock typically take place with semi-trailers, not forklifts. In fact, “struck-by” and “caught-between” injuries are two of the four leading causes of workplace fatalities. Given ambient noise and the distance between a loading dock and the engine of a semi-tractor trailer (which can be in excess of 20 m [66 ft]), inattentive dock yard workers may not hear a trailer backing toward them until it is too late.

With certain vehicle restraints, this motion-sensor system can be added as an upgrade.

Conclusion

As high-speed doors become more technologically advanced, they are not only increasing productivity across North America, but also safety. One of the leading reasons high-speed doors and blind spots are becoming less hazardous is because of GUI control panels and motion sensor/LED systems inside and outside the plant. It is important for building engineers and specifiers to understand the latest trends in these technologies to ensure the right equipment is considered in potentially hazardous areas.

![]() Jon Schumacher is the director of marketing for Rite-Hite Doors. He has been with the company for more than 20 years and is a former vice-chair of the Door and Access Systems Manufacturers Association (DASMA). Schumacher can be reached at jschumacher@ritehite.com.

Jon Schumacher is the director of marketing for Rite-Hite Doors. He has been with the company for more than 20 years and is a former vice-chair of the Door and Access Systems Manufacturers Association (DASMA). Schumacher can be reached at jschumacher@ritehite.com.