Designing with insulated metal panels

Vapour control in IMPs

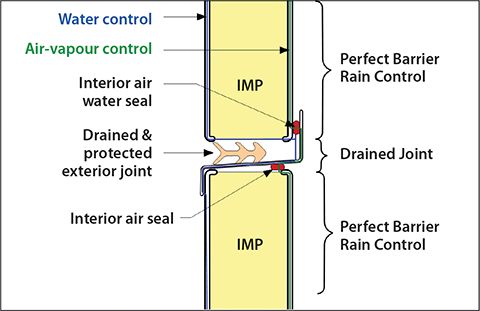

The steel skins of an IMP are perfect vapour barriers (i.e. 0 perm). At joints between panels, achieving a low-permeance vapour barrier is not very important, except in demanding applications with very high average differences in water vapour content (e.g. freezer warehouses, swimming pools, special-purpose factories). However, some vapour resistance should be provided.

In many cases, the backer rod and sealant used as an air barrier seal will also provide an adequate vapour barrier.

For high-interior-humidity environments such as swimming pools, however, open-cell foam backer rods and silicone sealant are usually too vapour-permeable. Urethane and butyl-based sealants over closed-cell foam backer rods can provide low-permeance vapour barriers. In all cold climate applications, a vented outer sealant is recommended to allow any moisture that may enter the joint from the interior to leave to the exterior.

Thermal control

The thermal control layer is clearly provided by IMPs in the form of the continuous foamed insulation layer. Thick panels, 100 mm (4 in.) and more, can provide high levels of thermal control. However, thermal bridging is a concern as it is in many enclosure systems. Care must be taken in the design of metal flashings, door frames, overhangs, and the like to limit the full-wall penetration of metallic components. Research for B.C. Hydro has shown even metal flashings can significantly decrease the overall thermal performance of systems in which flashing is used often or without thermal breaks. (The research for BC Hydro’s “Building Envelope Thermal Bridging Guide,” was conducted by Morrison-Hershfield in Vancouver, and published in 2014.) A 76-mm (3-in.) thick nominal R-21 panel would have an actual R-value of R-15.8 if horizontal flashings were located every 2.7 m (9 ft) on centre.

Conclusion

Insulated metal panels can provide all the components of a functional building enclosure in one component. Understanding the control layers used, and the rain control strategy employed, is important to achieve the best performance and avoid potential pitfalls. A vented, drained two-stage joint provides a single interior air and vapour barrier, with the outer seal acting as a vented rainscreen with little air or vapour resistance.

Connecting the control layers of other enclosure components with an IMP system in this manner can provide reliable, durable performance. As with most systems, achieving continuity at the joints between panels and between different components is critical.

John Straube, PhD, P.Eng., is a principal at RDH Building Science Laboratories, and a cross-appointed faculty member in the School of Architecture and the Department of Civil and Environmental Engineering at the University of Waterloo. He is also a prolific writer and a noted public speaker. Straube’s leadership as a building scientist and an educator has been recognized with multiple awards, including the Lifetime Achievement Award in Building Science Education from the National Consortium of Housing Research Centers (NCHRC). He can be reached at jfstraube@rdh.com.

John Straube, PhD, P.Eng., is a principal at RDH Building Science Laboratories, and a cross-appointed faculty member in the School of Architecture and the Department of Civil and Environmental Engineering at the University of Waterloo. He is also a prolific writer and a noted public speaker. Straube’s leadership as a building scientist and an educator has been recognized with multiple awards, including the Lifetime Achievement Award in Building Science Education from the National Consortium of Housing Research Centers (NCHRC). He can be reached at jfstraube@rdh.com.