Designing with foam plastic insulating sheathing

Stucco systems over metal lath involve a series of regularly spaced fasteners offset from the FPIS substrate. The offset fastener configuration prevents an adequate seal where the anchor penetrates the FPIS. To accommodate this issue, manufacturers may require either pre-striping anchorage points with FPIS accessory tape or fluid at stud locations, or the introduction of furring strips and pre-striping. This is not to mention quantity of attachment points for stucco (175 mm [7 in.] spacing at framing members)8 compared with standard 400 mm (16 in.) lateral tie spacing for masonry.

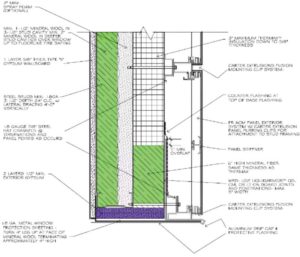

Metal panel systems, which are frequently attached to a subgirt system, present relatively fewer installation challenges. The girts can be sealed to the FPIS prior to cladding attachment, and no blind fastening through FPIS occurs. Metal cladding systems may be utilized in an open joint fashion; in this case, long-term ultraviolet (UV) stability should be factored into the design of the air and weather barrier system. Additionally, metal conductivity and related heat buildup may present a separate set of issues related to dimensional stability. Research has consistently shown that foamed plastics experience both elastic and inelastic (i.e. permanent) board deformation at elevated service temperatures.9 However, these studies typically focus on roofing type assemblies where conductive heat transfer should be anticipated.

Each cladding type will have its own series of nuances. This is not meant to sway a designer away from FPIS systems or from a certain cladding and FPIS pairing, but rather to bring attention to potential challenges presented by various product combinations. In general, any cladding system requiring direct attachment, concealed or exposed, will likely require supplementary steps to ensure a sealed penetration, as compared with a cladding attached to sub-framing.

Construction challenges

For every benefit, there is always a countering cost. This may become an actual financial cost, but typically this presents as a construction variable. There are several challenges designers should consider as they proceed with an all-in-one FPIS system.

Proprietary-like assembly

To achieve code compliance, FPIS systems require full assembly testing (ULC S134) to confirm several performance metrics–the result provides rating for an assembly of components working together. Testing is an expensive endeavor, and thus most manufacturers have only performed limited tests relative to the available products on the market. This means assembly components are not interchangeable. In construction, it is routine for product shortages, time constraints, or other limitations to necessitate a building component substitution.

In short, if a single assembly component is not available, the system may not be viable or may require modifications to meet testing or code requirements. For non-combustible assembly components, substitution options may abound. For combustible components, on the other hand, options may be severely limited. For example, if a manufacturer has a tested assembly with a specific closed cell spray foam which is not available, substituting an alternate spray foam may trigger significant detail changes (Figure 3 and Figure 4).