Designing with axminster carpets

Installing and designing with Axminster

The most common method of installing Axminster in hospitality interiors is the double-stick method. This involves a releasable adhesive to fully adhere a double-stick pad to the subfloor. Breadths of carpet are then ‘dry-laid’ per the provided seaming diagrams and design layouts (referred to as ‘flooded floor plans’), before being fully bonded to the pad.

Flooring experts suggest installers work to a central line at all times, keeping the patterns matched and aligned in both length and width. In order to ensure the carpet’s backing has sufficiently transferred into the adhesive, the carpet should be glided flat to remove all air pockets between the carpet and the pad. It is strongly recommended installers do not cover freshly installed Axminster carpet with any plastic products. They should instead use alternate coverings such as plywood or heavy-duty craft paper.

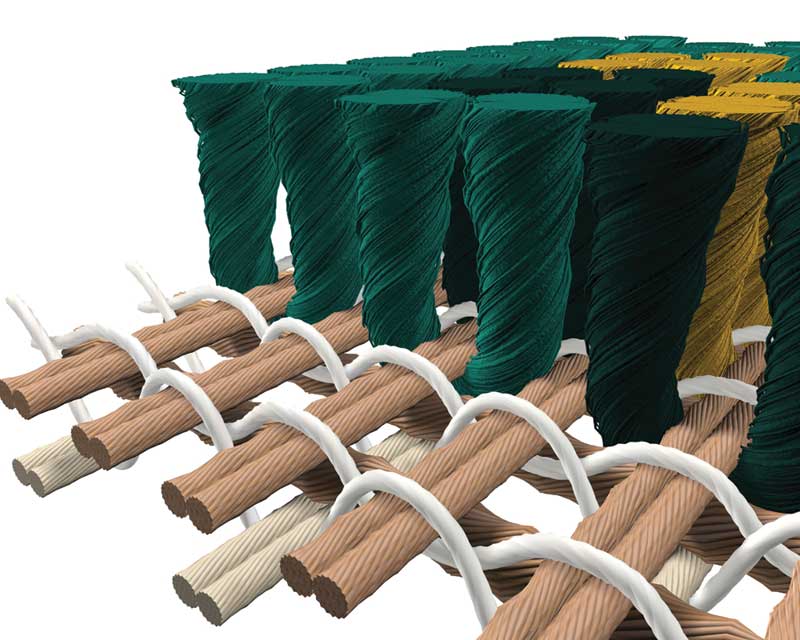

Similar to the construction, the design process has remained the same since the early days of Axminster. Designers would draft freeform drawings onto point paper, assigning each point on the paper to a coloured tuft of yarn. Today, this same principle is applied to CAD carpet design programs. Axminster has seven points per inch across the width (weft) of the loom, meaning there are seven pixels across an inch to design. The number of tufts per inch in the length (warp) depends on the end use. (For example, best practices include six tufts in guest rooms and up to 14 tufts in high-traffic public spaces). The introduction of CAD and the electronic Jacquard loom have enabled designers to achieve massive scale and design precision.

Conclusion

With advancements in technology, the process of designing and creating Axminster carpet will continually evolve. Improvements to looms will lead to quicker production times, while use of different yarn types to create texture will advance design. Improvements to sustainability will be a priority, as consumers push for less waste, leading to an increase in the use of natural materials, such as wool. Through all these improvements and advancements to designing and weaving carpet, one thing should stay the same—the integrity and strength of the floorcovering due to sound construction.

Johnny Massey is the vice-president of operations for Brintons Americas and has been with the company since 1999. He graduated from Mississippi Delta Community College with a degree in graphic design. Massey can be reached via e-mail at Brintons@brintonsusa.com.

Johnny Massey is the vice-president of operations for Brintons Americas and has been with the company since 1999. He graduated from Mississippi Delta Community College with a degree in graphic design. Massey can be reached via e-mail at Brintons@brintonsusa.com.