Design considerations in engineered wood floor systems

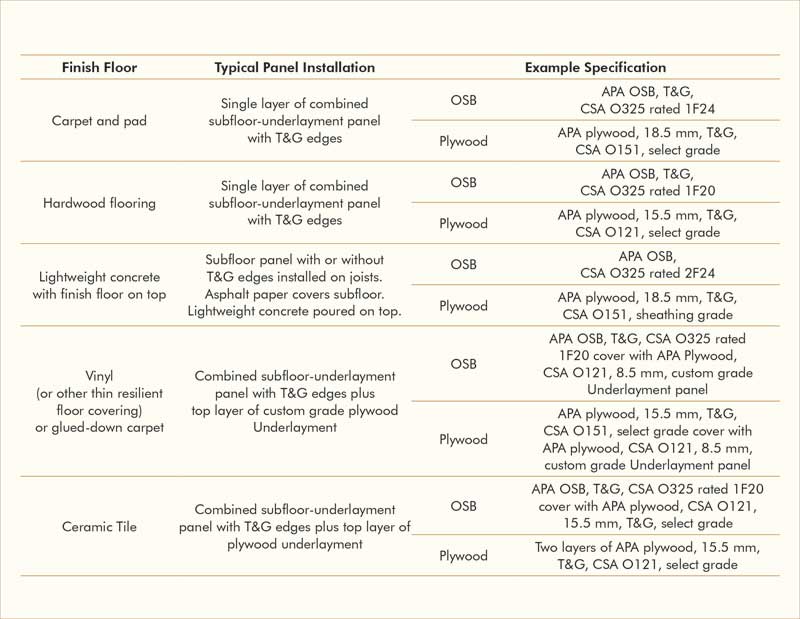

To select appropriate products and floor design, it is essential to define the predicted loads and to consider both the structural requirements and compatibility with the finish floor requirements. Figure 1 shows the most common finish floor products and the underlying structural floor systems typically recommended for each.

APA–The Engineered Wood Association is a nonprofit trade association of engineered wood product manufacturers, ranging from small, independently owned and operated companies to large integrated corporations. APA represents approximately 169 mills throughout North America. Its design recommendations for floors are based on extensive testing at the association’s laboratory and observations in the field.

Glued floor system for solid performance

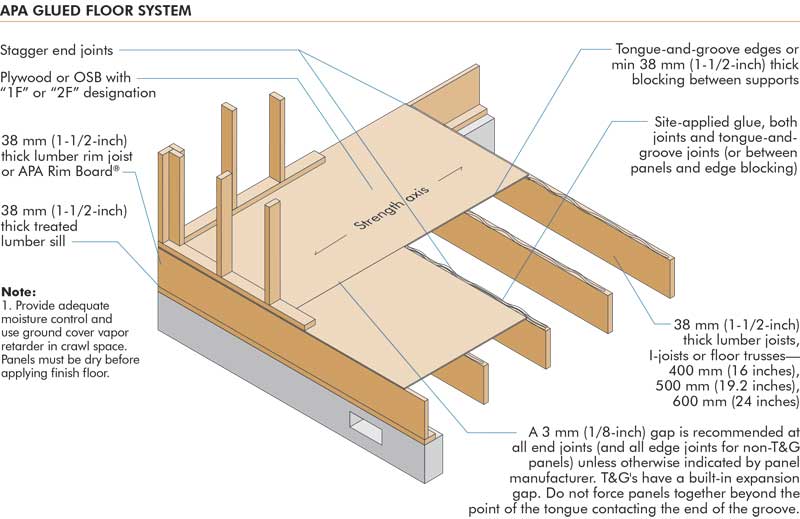

Recommended by APA−The Engineered Wood Association, the glued floor system shown in Figure 2 is based on thoroughly tested gluing techniques and field-applied construction adhesives that firmly and permanently secure a layer of wood structural panels to wood joists. The glue bond is so strong floor and joists behave like integral T-beam units.

Floor stiffness is increased appreciably over conventional construction, particularly when the tongue-and-groove joints are glued. Gluing also helps significantly reduce squeaks, floor vibration, bounce, and nail-popping.

Field-glued floors go down quickly, even in cold weather, using ordinary construction materials and techniques. Like many other panel assemblies that provide excellent sound control, the APA system is ideal for multifamily construction. The large panels with glued tongue-and-groove joints reduce the number of cracks that can ‘leak’ airborne noise.

Tongue-and-groove panels recommended for glued floor construction include OSB with a 1F designation for single-floor construction and APA plywood, which can be either ‘Select’ or ‘Select Tight-face’ grade. Both of these options require B-grade veneer faces, following CSA O121. (Select Tight-faces have further grade restrictions that do not permit small face gaps that ‘Select’ faces permit.)

APA plywood (sheathing grade with square edge) or OSB with a 2F designation for the subfloor may be used for a glued floor construction if employed with a separate underlayment layer or with structural finish flooring. Tongue-and-groove panels are recommended for single-floor construction. In both cases, subfloor panels should be installed continuous over two or more spans with the long dimension or strength axis perpendicular to supports.

A single layer of tongue-and-groove plywood (Select or Select Tight-face grade) is allowed under areas to be finished with resilient floorcoverings, such as ceramic tile, sheet linoleum, sheet vinyl, or fully adhered carpet, although an additional layer of plywood underlayment is recommended. Care must be taken during construction to prevent damage or roughening of the sanded face that will receive the finish flooring. Both OSB (for subflooring) and plywood (for subflooring and underlayment) have suitable bond performance for applications subject to moisture during or after construction, as in restrooms and utility rooms.

Before each panel is placed, a line of glue is applied to the joists with a caulking gun. The panel tongue-and-groove joint should also be glued, although less heavily, to avoid squeeze-out. If square-edge panels are used, edges must be supported with a minimum 38-mm (1 ½-in.) thick blocking securely nailed between framing members. The panels can be glued to blocking in order to minimize squeaks. Blocking is not required under structural finish flooring, such as wood strip flooring, or if a separate underlayment layer is installed.

Only adhesives conforming to ASTM D3498, Adhesives for Field-gluing Plywood to Lumber Framing for Floor Systems, or APA Specification AFG-01, Adhesives for Field-gluing Plywood to Wood Framing, are recommended for use with the APA glued floor system. A number of brands meeting this specification are available. If OSB panels with sealed surfaces and edges are to be used, one should only employ solvent-based glues. (It is important to check with the panel manufacturer and always follow its specific installation recommendations.)