Demystifying self-consolidating concrete

Production of SCC

Photo courtesy Hanson Ready Mix

All the materials need to be thoroughly mixed to become a homogenous mass. If there is one thing to stress, it is that consistency is key, as SCC mixtures are very sensitive to fluctuation. A comprehensive total quality plan is essential to ensuring stable performance. Aggregate moistures and drum water can be particularly aggravating if uncontrolled.

The concrete must not be over or under mixed. The required mixing time depends on the volume of concrete in the mixer, the type of mixer, and the mix design itself. With proper mixing, all the materials will have intimate contact with each other and admixtures will be properly activated to achieve the needed slump and air-void parameters. Over mixing of concrete can cause a decrease to the slump, air, and strength. Generally, there exists about a two-hour window from the time of batching to when the concrete must be placed (which is affected by ambient conditions and use of accelerators or retarders). Past this time, the concrete is beginning to set and further manipulation will break the newly forming bonds, resulting in lower strength and durability.

Specifying and testing of SCC

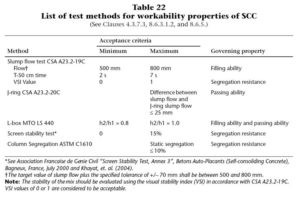

The specification, performance, and conformity requirements for SCC can be found in Section 8, “Concrete with special performance or material requirements,” of the Canadian Standards Association (CSA) A23.1-14, Concrete materials and methods of concrete construction / Test methods and standard practices for concrete, and should follow the performance alternative illustrated in the standard’s Table 5, “Alternative methods for specifying concrete,” where the owner specifies the performance requirements for the concrete mix instead of prescribing material sources and quantities. The workability of SCC is described in Table 22 of CSA A23.1-14, where each property should be independently evaluated and the requirements also vary based on the particular application (Figure 6).

The workability requirements are best addressed by the designer, contractor, and producer discussing the project requirements together. Characteristics should be carefully selected and controlled based on experience with the mix or pre-placement trials. Specific requirements for SCC in the fresh state depend on the type of application, and especially on:

- confinement conditions, concrete element geometry, and congestion of reinforcement;

- placing equipment and methods;

- finishing methods and architectural needs; and

- ambient conditions.

Generally, as the reinforcement level, length or depth of the element, or element-shape intricacy increase, or the space between walls decreases, higher slump flows and viscosity and segregation resistance are required. For information on selecting the appropriate plastic properties, it is recommended to refer to ACI 237, Self-Consolidating Concrete, or the European Guidelines for Self-compacting Concrete.

Certification

As the usage of SCC continues to evolve, there is a need to ensure technicians are equipped with the necessary tools to properly test the performance characteristics of the concrete. To help provide these tools, ACI has recently announced a SCC testing technician certification course featuring the following five test methods:

- ASTM C1610, Standard Test Method for Static Segregation of SCC Using Column Technique;

- ASTM C1611, Standard Test Method for Slump Flow of SCC;

- ASTM C 1621, Standard Test Method for Passing Ability of SCC by J-Ring;

- ASTM C1712, Standard Test Method for Rapid Assessment of Static Segregation Resistance of SCC Using Penetration Test; and

- ASTM C1758, Standard Test Method for Fabrication of a Test Specimen with SCC.

Similar to other ACI courses, the certification consists of written and performance exams and is valid for five years. The certification is offered through ACI’s global network of more than 120 sponsoring groups, including the ACI Ontario Chapter and Concrete Ontario.