Creating air barriers on exterior walls with spray foam

Air barrier systems

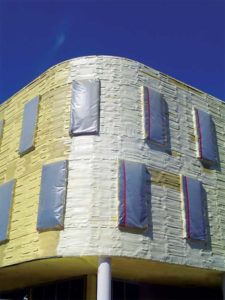

In the CCMC air barrier system evaluations, the medium-density SPF product is considered as the principal material in the plane of airtightness. To qualify as an air barrier system, the wall needs to accommodate movements of building materials, and provide connections to adjacent materials to prevent air leakage at all critical locations including connections, joints, and penetrations. An extensive number of tests are conducted to receive the air barrier system designation.

To achieve air barrier system compliance, it is recognized the use of medium-density, spray foam products in exterior ci wall applications requires membrane materials (self-adhered or liquid) to provide optimum performance. Consequently, a great deal of effort in field evaluations and product compatibility testing has been made by manufacturers to define the components of such a system and where they should be used.

Design and performance considerations

The use of medium-density spray foam insulation in exterior ci applications provides architectural firms and commercial building contractors an opportunity to positively impact their construction schedules, budget, and overall performance quality. Additionally, medium-density spray foam insulation in exterior ci applications offers many benefits including:

- cover the widest range of exposed surfaces to prevent thermal bridging;

- features an approach to air- and water-resistive barrier

(A/WRB) creation not dependent on extensive use of joint sealants in exposed situations; - has a good ability to bond to the entire length of wall penetrations, such as brick ties and fasteners, thereby ensuring thermal and airtightness effectiveness;

- is likely to have air barrier discontinuity at transitions and control joints;

- has very low water absorption and is capable of shedding water; and

- can be applied in cold temperatures as low as -10 C (14 F).

There can be challenges associated with SPF exterior ci, but most of them can be overcome with attention to details and pre-application planning. Dry and non-windy weather conditions are necessary to facilitate optimal product adhesion and limit over-spray situations. The application area should be isolated and other construction trades restricted from entering. One should confirm the substrates the spray foam will be applied to are compatible with it. A plan must be developed to ensure wall penetrations, including windows, doors, anchors, and attachments, are covered or will be remediated so the spray foam does not affect their long-term operation.

Using open-cell, low-density spray foam insulation

Although it has most often been associated with residential construction, low-density spray foam can also be employed on the interior side of a commercial building. Its air-sealing characteristics allow it to qualify as an air barrier material. Many spray foam manufacturers have the appropriate test information to confirm that ability. Therefore, using open-cell spray foam within a wall cavity, with either metal or wood studs, can constitute the main component of an air barrier system. Its use also means expensive air membranes on the exterior of the wall sheathing can be avoided or scaled back in scope, thereby reducing construction costs. Open-cell spray foam can be sprayed on cold substrates, and therefore can be employed in cold weather applications. It can be used for applications on wood-based substrates. It is also compatible with concrete, masonry, and steel. Open-cell spray foam can be cut fairly easily allowing for changes, such as adding an electrical box within a wall stud cavity, to occur more simply.

Open-cell spray foam insulation effectively blocks heat transfer with a tested thermal performance of approximately 0.66 to 0.72 (m2•K)/W (R-3.7 to R-4 per in.). Its lower density gives it a comparatively softer make-up than denser, closed-cell insulation, meaning it can also seal around the edges and perimeter of stud cavities and any penetrations in a flexible manner. Some of the other benefits of open-cell insulation are tied to this lighter, softer, and more flexible make-up. Acoustic control, for example, is enhanced in wall assemblies due to its flexible and absorptive properties, more so than with rigid insulation. Should water infiltrate the assembly for any reason, its vapour permeability means the material can dry both toward the interior and the exterior as may be preferred. As a material, it does not provide a food source for mould. The cost of open-cell spray foam insulation is generally very attractive and competitive when compared to labour and materials for other types of insulations.

Installing spray foam insulation within building interior assemblies is typically less challenging than exterior applications. Isolating the application area and having the substrates ready for spraying are still necessary. Further, the building construction should be far along so the installed SPF will not be subject to weather. If windows are not in place it is good practice to cover their openings.

As with all construction products, installation is critical to the performance of the material and development of a high performing wall air barrier. Spray foam installers who have successfully undergone training at the hands of manufacturers or a trade association are more likely to deliver the installation needed. Specifically, the Canadian Urethane Foam Contractors Association (CUFCA) has an installer certification process including training and licensing.

The advantages of using spray foam insulation to create an air barrier on exterior walls are numerous. Using medium-density SPF products in an exterior ci wall application has been proven to create an airtight assembly, and is becoming widely specified. Meanwhile, low-density SPF products are a cost-effective approach to creating airtightness within wall stud cavities. In both cases, the result is a more energy efficient building.

![]() John Broniek is senior engineer for Icynene-Lapolla where he provides product use recommendations to all external audiences including designers, applicators, and building owners. He also acts as a building science technical resource to Icynene-Lapolla’s sales team and dealers. Broniek has been involved in improving the energy efficiency and durability of buildings throughout North America since 1990. He can be reached via e-mail at jbroniek@icynene-lapolla.com.

John Broniek is senior engineer for Icynene-Lapolla where he provides product use recommendations to all external audiences including designers, applicators, and building owners. He also acts as a building science technical resource to Icynene-Lapolla’s sales team and dealers. Broniek has been involved in improving the energy efficiency and durability of buildings throughout North America since 1990. He can be reached via e-mail at jbroniek@icynene-lapolla.com.