Controlling condensation from air leakage and vapour diffusion

Exterior climate and interior conditions

Building design and material specification highly depend on climate zone. Many of today’s building failures are caused by designers and builders taking a concept that worked in one climate zone and applying it to another. A good example of this was during the ‘leaky condo crisis’ in and around Vancouver in the late 1980s to early 2000s, which led to widespread building failures. A survey of building envelope failures in the area concluded face-sealed wall assemblies were unacceptable in the region. Once wetted, the drying potential for drying in these walls in the coastal climate of the lower mainland during the winter is very limited. (For more see, D. Ricketts and J. Lovatt’s “Survey of Building Envelope Failures in the Coastal Climate of British Columbia,” published by Morrison Hershfield and Canada Mortgage and Housing Corporation [CMHC] in 1996.)

Interior conditions also dictate how the building assembly should be designed and constructed. For example, vapour diffusion can be a significant moisture transport mechanism in buildings with higher interior humidity levels (e.g. hospitals, museums, and natatoriums). However, most buildings will have an interior relative humidity (RH) level in the 20 to 35 per cent range during the heating season. In this condition, the potential for vapour diffusion condensation is small; it can be easily managed with the correct material selection, insulation, and construction practices.

Vapour-open assemblies

Although vapour barriers are intended to prevent assemblies from getting wet, they also often prevent them from drying. Vapour barriers installed on the interior side of assemblies impede them from drying toward the interior—this is a problem for air-conditioned spaces, and can be an issue when there is also a vapour-impermeable material installed on the assembly’s exterior, creating a double-vapour-barrier wall assembly. Therefore, it is practical to encourage drying mechanisms over wetting prevention mechanisms—meaning one should avoid using vapour barriers if vapour retarders will work, and avoid using vapour retarders when vapour-permeable materials suffice.

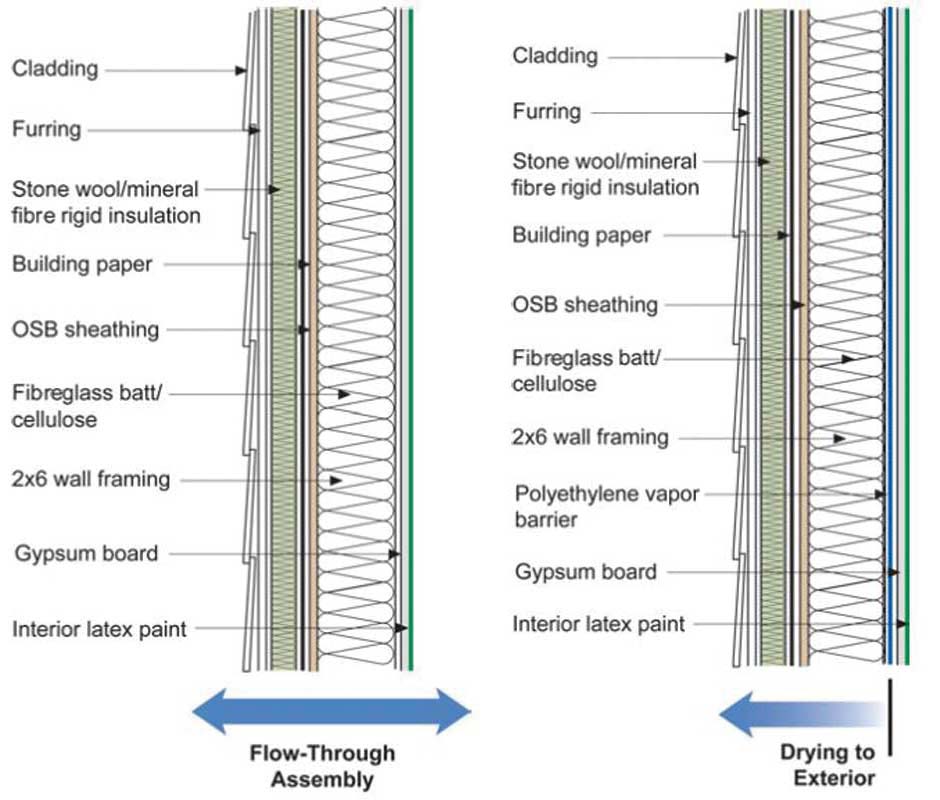

A high-performance flow-through wall can be achieved by using materials that allow vapour to pass through it, as seen in the left side of Figure 2. This wall assembly works in any climate zone. The ventilated cladding—along with the vapour-permeable exterior stone wool insulation, vapour-semi-permeable oriented strand board (OSB) sheathing or permeable gypsum sheathing, and vapour-permeable cavity insulation (e.g. stone wool) between wood or steel framing—allows any accumulated moisture to dry in either direction.

Adding a polyethylene vapour barrier on the interior eliminates drying toward the interior, as shown on the right side of Figure 2. Air-conditioning the interior with this type of assembly may lead to moisture-related issues, as condensate may collect on the polyethylene sheet during the summer.