Concrete Cracking Problems: A modern-day phenomenon?

In addition to the well-known concerns when placing any type of concrete during hot weather, high-ambient temperatures can also adversely influence autogenous shrinkage cracking. This is because the heat of hydration reactions—and thereby internal self-desiccation—occur more rapidly and at a time when tensile strength development may not be adequate to resist the resulting autogenous volume change. Since the reactions are adversely influenced by high ambient temperature, there is also a possibility that differential autogenous shrinkage can result, concentrating strain development within the surfaces exposed to the higher temperature. The problems can have even greater consequences for mass concrete containing high cement contents.

According to ACI 224.1R, Causes, Evaluation, and Repair of Cracks in Concrete Structures, shrinkage cracking can be controlled by using contraction joints and proper detailing of the reinforcement. Well-defined reinforcement allows the development of stress well beyond that corresponding to maximum stress, permitting concrete to typically withstand greater volume change. Therefore, unreinforced concrete, toppings, overlays, etc., are much more likely to crack for concrete susceptible to high levels of internal self-desiccation (Figure 4). The degree of restraint or relaxation can have a considerable influence on whether volume change can cause cracking. Relaxation provided by the properties of modulus of elasticity and creep is often sufficient to prevent shrinkage cracking at early ages for conventional concrete. However, both of these properties are well-known to potentially have less influence when HPC or high-strength concrete is selected.

When does shrinkage stop?

It has already been stated that autogenous shrinkage takes place very early in the hydration process and can continue for several weeks, if not months. It has also been inferred that drying shrinkage can add to the strains generated by autogenous shrinkage and subsequently cause cracks to occur. Carbonation shrinkage, which typically can take years to occur to any degree, can also impose a cumulative effect on strain development, has also been discussed. So when does total shrinkage stop?

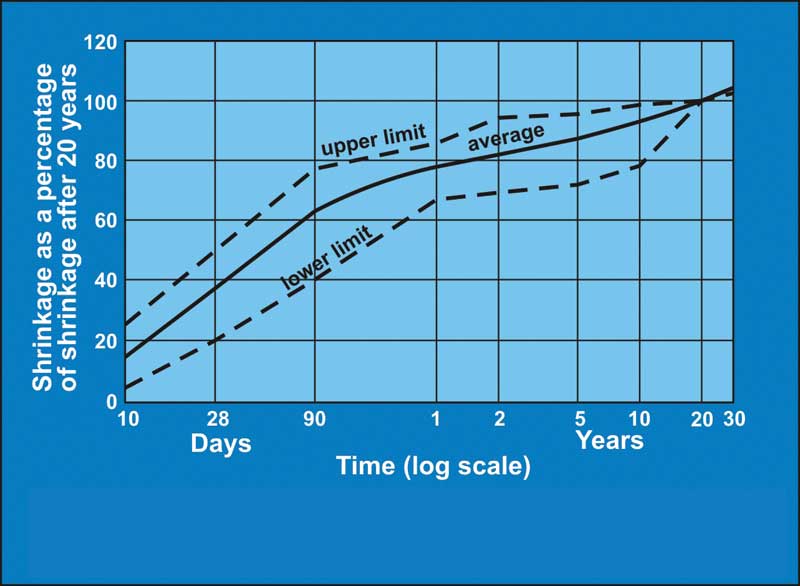

In Properties of Concrete, Neville states shrinkage takes place over long periods: “some movement has been observed even after 28 years, although a part of the long-term shrinkage is likely to be due to carbonation[.]” From the data he provides, it can be observed for the average of the concrete that was studied, about 40 per cent of the total shrinkage occurred after 28 days and about 80 after one year. The rate of shrinkage then decreased rapidly with time (Figure 5). However, the study Neville includes in his book was published in 1958, which is well before the introduction of the materials and technology used today. It is therefore logical that an even greater effect can be expected when modern concrete materials and mix designs are used.

Mitigating autogenous shrinkage cracking

Established good concrete protection practices are still essential if cracking of conventional concrete is to be prevented or mitigated. However, as already discussed, even efficient wet-curing techniques may not be sufficient to prevent cracking of concrete that is susceptible to severe autogenous shrinkage. Perhaps the best way in which this type of cracking can be addressed is by selecting a concrete mix design that avoids high cement content, as well as low w/c ratios (below about 0.45), and high levels of supplementary

cementing materials. High rates of superplasticizer addition should also be avoided.

If this is unavoidable, then the use of some non-conventional materials or techniques could prove beneficial, although trials are recommended in advance of use so that any side effects can be fully understood. Some of the methods have been developed to provide the benefit of what has become known as internal curing, and include the use of fine, saturated lightweight aggregates and saturated super-absorbent polymers. Both of these provide an internal source of water to replenish moisture lost during self-desiccation reactions. Saturated, fleece-lined, controlled permeability formwork has also been used although the availability of moisture is limited to the immediate interfacial zone of concrete.

Shrinkage-reducing admixtures, typically utilized to counter drying shrinkage, can also be used to mitigate autogenous shrinkage cracking; these materials are designed to alter the surface tension of the pore water, thereby reducing the capillary stresses developed during desiccation—whether self-induced or by evaporation. Expansive cement or shrinkage-compensating cement technology has also been used to counter the volume reduction due to autogenous shrinkage by the development of initial expansion. Finally, the addition of fibres may also have a beneficial influence on the early-age cracking of concrete; although fibres do not typically reduce the shrinkage of concrete, they can increase the resistance to crack propagation and reduce crack width and frequency.