Combating radon with scientific research

Testing active soil depressurization systems

Active soil depressurization systems have been used in 80 per cent of professional mitigation cases in North American homes. (For more, see R. Wood’s “Cold Climate Radon Mitigations: A Canadian’s Perspective” at ftp.cmhc-schl.gc.ca/chic-ccdh/Research_Reports-Rapports_de_recherche/eng_unilingual/Ca1%20MH%2010C51_W.pdf.) Although the effectiveness of these systems with indoor radon control has been widely recognized, their impacts and insulation requirements in Canada’s cold climate were previously not fully understood. Between 2012 and 2016, experiments were conducted during winter months in the twin houses of the CCHT—a facility jointly operated by NRC, Natural Resources Canada (NRCan), and the Canada Mortgage and Housing Corporation (CMHC).

These experiments demonstrated the continuous operation of an active soil depressurization system would increase the heating-energy consumption of the house by five per cent annually, and cool down the concrete slab by 2 C (3.6 F). Interestingly, the test results also indicated active soil depressurization systems had insignificant influence on basement air pressure and temperature, soil temperature profiles, and the frost line around the houses. The tests further showed an insulation value of R-14 around the active soil depressurization stack was sufficient under the winter test conditions to avoid ice blockage.

Additionally, tracer gas experiments conducted in the IARL suggested gable-end exhaust at eaves level is a viable solution for routing active soil depressurization termination points to prevent freeze-up/icicle formation. It was also discovered the operation of active soil depressurization would only pose a limited risk of back-drafting from combustion appliances (e.g. wood-burning stoves and natural gas fireplaces).

The CCHT facility has recently been expanded and modernized to represent the trend toward smaller, multi-unit housing and increasingly airtight, energy-efficient design. Four radon prevention and control systems have further been installed in this new facility. Investigations on the performance and impact of these systems will be carried out in the next two to three years.

To position Canada at the forefront of radon control research and assist the building industry in developing radon-ingress solutions tailored to the Canadian climate, the NRC radon research team, in collaboration with Health Canada, developed the world’s first Radon Infiltration Building Envelope Test System (RIBETS),which has been in use since 2013.

Test methods

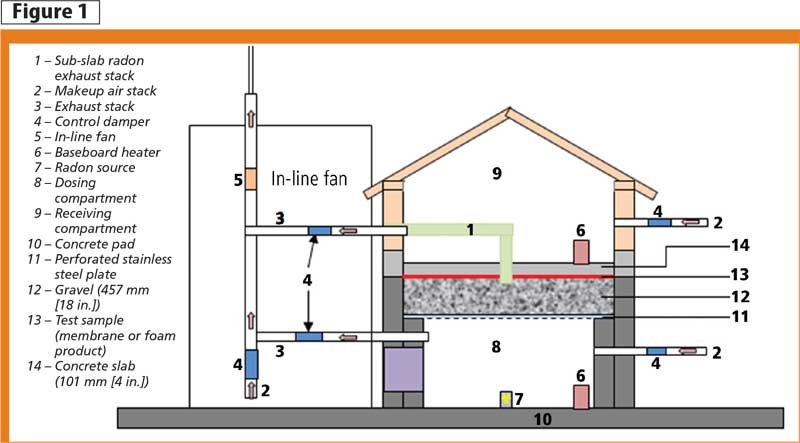

RIBETS is a controlled testing system, characterized by a mockup house with a 2 x 2-m (6 x 6-ft) footprint where radon can be introduced in a controlled fashion into the sub-slab area (Figure 1). Floor assemblies containing innovative products such as membranes, concrete, foam board, sprayed polyurethane foam (SPF), concrete forms, drainage systems, or sub-slab ventilation panels can be installed according to manufacturers’ installation guides, then evaluated for their efficiency related to radon prevention and mitigation. The ductwork design of the system makes the facility an ideal test bed to investigate the effectiveness of demand-controlled HVAC components such as heat or energy recovery ventilators, which can also be used for reducing indoor radon level.

Within the first two years of completion, RIBETS had already served five Canadian firms by evaluating various types of innovative products. Performed in conjunction with NRC’s Canadian Construction Materials Centre (CCMC), these tests enabled manufacturers to enter new markets by demonstrating their products’ code compliance as alternate solutions. One client was even able to use the RIBETS results to gain compliance with International Code Council (ICC) standard ICC-AC461, An Alternate Gas-permeable Layer of a Sub-slab Depressurization System for Radon Gas Control, opening up the U.S. market to the product.