Cold storage: How smart roof design saves energy

What about roof attachment?

This article has discussed the concept of thermal bridging and how energy loss occurs at discontinuities between the joints of the insulation, but thermal bridging can also occur where there are fastener penetrations through the roof system, as seen in Figure 1 on page 31.

Fasteners are used to attach the insulation and the membrane to the roof deck, which is referred to as a mechanically attached system. A way to reduce the thermal bridging at fastener penetrations is to bury them in the system or eliminate them altogether and install an adhered roof system. An adhered roof system typically fastens the bottom layer of insulation to the deck level, with subsequent layers of insulation, membrane, and roof cover board, adhered. By eliminating the fasteners, the path for air to travel into the roof system is also reduced.

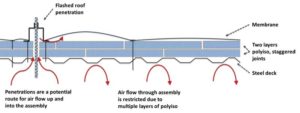

Figures 2 and 3 illustrate good and better scenarios, in terms of limiting thermal bridging and reducing air flow into the roof assembly. In Figure 2, labelled as the “good” scenario, there are multiple layers of insulation, staggered and offset, but they are mechanically attached to the deck. While the staggered insulation layers limit some of the air flow into the roof assembly, air is still able to travel throughout the roof.

In Figure 3, labelled as the “better” scenario, only the first layer of insulation is mechanically attached, and subsequent layers are adhered. By adhering the subsequent layers, air flow into the roof assembly is reduced, maintaining interior temperatures, and aiding in energy savings.

Devil in the details

The result of limiting air flow through the roof assembly of a cold storage facility is not a matter of occupant comfort, but of occupant safety. In a traditional building, such as an office, a poorly detailed roof termination could result in drafty offices or temperature complaints. In a cold storage facility, those same drafts condense due to the large temperature differential between the interior and exterior of the building, and the condensation can turn into ice.

The ice can form on various surfaces, including locations where air leakage is occurring, such as at roof-to-wall interfaces, but also on the cold storage floors where the surface of the floor is cooler than the air above it. When ice forms on the floors, it can cause slips or falls, and can also impact operations if a particular area of the facility must be avoided.

Ice formation inside a cold storage facility is the result of improperly designed or executed details. Details, such as those at the wall-to-roof interface, or sealing around penetrations, are crucial to preventing condensation and conserving energy in the facility.

Like the loss of energy created by thermal bridging, air flow through the roof created by poor detailing results in considerable loss of the cooled temperatures in the space below. Condensed air flow can also collect within the roof assembly (including in the insulation), and freeze.

Frozen insulation is a common side effect of a cold storage roof not functioning properly. Frozen insulation is exactly what it sounds like—insulation that has had moisture accumulate within it and freeze. Frozen insulation has properties similar to wet insulation and is ineffective since it provides virtually no insulating properties. A frozen roof is almost like having no insulation at all, and the energy used to maintain the interior temperatures skyrockets.

Proper planning reaps benefits

Proper detailing of a cold storage facility begins during the planning stage. The type of interior spaces, the sizes, and overall usage of the facility should be taken into consideration. Once the overall layout of the cold storage facility is decided upon, the construction materials, including the roof assembly, must be determined.

Once the roof assembly is selected, design of the roof details is crucial. Typical details, including roof-to-wall interface and penetrations, must be meticulously designed. Roof-to-wall interfaces and penetrations must be sealed to prevent air from entering the roof assembly. Even the smallest gap allowing air flow can have detrimental effects on the roof assembly.

The most common method of ensuring sealed terminations and penetrations of a roof assembly is the use of a closed-cell spray foam. Closed-cell spray foam is typically installed at the intersection of the exterior walls and the roof insulation at a width of 25 mm (1 in.) and extends from the deck level to the top of the insulation.

At wall-to-steel deck intersections, it is also best practice to install spray foam in the deck flutes a minimum of 300 mm (12 in.) from the wall. The closed cell spray foam helps to seal the interface so air cannot enter the roof assembly.

Proper execution of the roof installation is critical and requires a contractor with cold storage construction experience. Having the right partner who understands the importance of their role in the project and collaborates with the team can make or break the roof installation.