Cold storage: How smart roof design saves energy

By Jennifer Keegan, AAIA and Kristin Westover, P.E., LEED AP O+M

By Jennifer Keegan, AAIA and Kristin Westover, P.E., LEED AP O+M

The headaches of cold storage facility operations extend beyond making sure the ice cream doesn’t melt. Owners and operators are regularly challenged with selecting a cost-effective roof system that is going to be long-lasting, lest they be forced to work around unsafe areas in the interior due to ice accumulation and struggle to reduce monthly energy bills.

For property owners who are looking to increase energy savings, a cold storage roof not only needs to keep the weather out but also helps resolve operational and safety issues. Cold storage buildings are designed to maintain cold temperatures—at much lower levels than a typical building. Cold storage facilities, such as blast freezers, may be required to maintain an interior temperature of -45.5 C (-50 F).

Having a structure properly insulated and sealed to maintain the required temperature and minimize ice build-up is important not only for the products being stored inside, but also for potential energy savings over the life of the facility.

How roofing materials can positively impact energy savings

Think of the walls of the cold storage facility as a jacket, and the roof as a hat. When it is cold outside, you want to make sure you have a jacket and a hat on to insulate your body and keep you warm. The same idea applies to a cold storage facility—the roof and walls of the structure insulate the products inside. In this case, when it is warm outside, they keep the products inside cold.

Not having enough insulation, in either the walls or the roof system, will make mechanical systems work harder to maintain the interior temperatures, increasing energy use and contributing to higher energy bills.

The effectiveness of roof insulation is determined by its R-value. According to Energy Star, R-value is a measure of an insulation’s ability to resist heat traveling through it. The higher the R-value, the better the thermal performance of the insulation and its effectiveness at maintaining interior temperatures. R-value is typically expressed as a value per inch of insulation, and the recommended R-value of cold storage spaces varies based on the interior temperature, although they are much higher than typically recommended for a traditional building.

For comparison, a traditional office building may require an R-value of 30. In the 2018 edition of the American Society of Heating, Refrigeration and Air Conditioning Engineers’ ASHRAE Handbook–Refrigeration, there are suggested minimum R-values for roof insulation between 30 and 60, depending on the cold storage type:

R-values will vary by product, including factors such as thickness and density. When calculating the total R-value of a multilayered installation, adding the R-values of the individual layers will provide the total R-value in the system. Particularly in cold storage applications, it makes sense to select an insulation with a higher R-value per inch, such as polyisocyanurate (polyiso, R-5.6 per inch), extruded polystyrene (XPS, R-5.0 per inch), or expanded polystyrene (EPS, R-3.8 per inch).

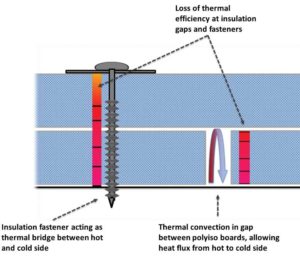

While insulations come in many thicknesses, it is a best practice to install several layers of thinner insulation rather than one or two layers of thicker insulation. This reduces thermal bridging, which occurs when insulation is discontinuous between joints, allowing for air and thermal movement between the joints or gaps between boards and fasteners (see Figure 1).

During installation, the use of several layers of insulation allows for staggering and offsetting the insulation joints and blocks the passages that allow for air to bypass the insulation. Limiting thermal bridging can increase energy efficiency, as it limits air movement between insulation boards.

Adding adequate insulation will prevent uncontrolled loss of the interior conditioned air and assist in maintaining required interior temperatures. Better maintaining the interior conditioned temperatures means the cooling systems are required to run less often, which can lead to energy savings.

While there may be an additional upfront cost to install an additional layer of insulation to increase the overall R-value of the roof, the cost should be minimal compared to the long-term savings of the added insulation. Of course, energy cost savings are not guaranteed, and the amount of savings vary based on climate zone, utility rates, radiant properties of roofing products, insulation levels, HVAC equipment efficiency and other factors.

What about the roof membrane?

While there are many choices for the type of roof membrane specified, the most common discussion regarding energy efficiency revolves around colour of the membrane. For a typical building, maintaining a comfortable space involves both heating and cooling, depending on the season. For the typical building, the colour selection of the membrane has a greater effect when the interior of the building is being cooled.

A highly reflective (light coloured) roof membrane offers extra benefits when the interior is being cooled, because it will reflect heat from the sun. Similarly, for a cold storage building, it is beneficial to select a lighter-coloured roof to reflect the heat from the sun AND assist in reducing the high costs of cooling the building. Reflecting heat from the sun will decrease the heat radiating into the interior, which means the cooling equipment will not have to work as hard to maintain interior temperatures and will ultimately work more efficiently.