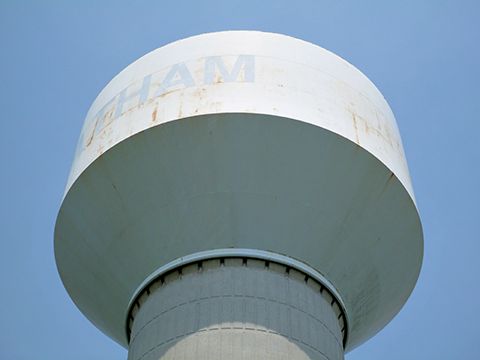

Coating Hybrid Tanks: Communities awash in water coating projects

Coating crews generally consist of six to seven workers with two teams of two working on the tower, one or two workers on the ground where they watch for hazards and prepare materials, and a quality assurance (QA) superintendent in charge of onsite safety and record-keeping. Protecting workers from exposure to old coatings containing lead or other harmful chemicals is an important requirement involving special training, use of personal protective equipment (PPE), and onsite safety monitoring.

Approximately half the OCS projects Historic Restoration sees involve overcoating an existing coating system found to be in sound and stable condition. Unlike a recoat project requiring abrasive blasting to remove old coatings down to bare metal, surface preparation for an overcoat consists of power washing and power tool cleaning to remove loose mill scale, rust, paint, and other foreign matter. Overcoating crews usually work in swing stages suspended from the top of the tank or from a crane and basket.

The majority of water tank renovations occur between April and May, or from August to November. Smaller communities usually require water tanks to be in service during the peak demand months of July and August, while larger municipalities with multiple water towers or reservoirs can often remove a water tank from service for maintenance without affecting the water system’s normal operation.

Coating work in underground reservoirs is usually scheduled during the winter when demand for water is low, according to Anthony Parente, who works with the Region of Peel in the Greater Toronto Area (GTA).

Underground reservoirs, representing most of the water storage facilities in the Region of Peel, are inspected every three years for damage to interior concrete and exposed metal caused by corrosion from chemicals used to treat the water. The region owns 35 reservoirs that have capacities ranging from about

37 to 170 million L (10 to 45 million gal).

Some of the region’s reservoirs have been in service since the 1950s and were poorly constructed or neglected by previous owners resulting in various levels of damage to concrete walls and support columns.

On being transferred to the Region of Peel, the reservoirs came under Parente’s comprehensive inspection program that revealed concrete infrastructure had degraded by a 6.35 mm (1/4 in.) or more, requiring a system-wide restoration effort.

During restoration, reservoirs had to be lit, heated, and dehumidified to achieve the proper conditions for coatings to be applied to concrete. The majority of older reservoirs had a single access point resembling a manhole shaft, making it difficult to bring in equipment required for the restoration. In many cases, structural modifications to these openings were needed to accommodate equipment and material movement.

Once the equipment was installed, it took about two weeks to bring the temperature and humidity to a condition where crews could work inside the reservoir. Projects can last from a few weeks to several months, depending on the amount of concrete damage that needs to be repaired.

Most reservoirs lie under public parks and athletic fields, so the presence of construction equipment may sometimes be an inconvenience to those using these amenities. To minimize disruption, extensive efforts were made to suppress noise from equipment and minimize safety hazards during renovation work.

Degraded walls and support columns inside the reservoirs were abrasive blast-cleaned to achieve a suitable surface for a protective coating system to be applied. Support columns damaged beyond repair were replaced.

A cementitious repair mortar was trowel-applied to severely deteriorated concrete surfaces to prepare them for top coating with a spray-applied, high-performance epoxy certified by NSF International in accordance with NSF/ANSI 61.