Cement and concrete, still outperforming in the sustainability era

How is the industry addressing sustainability?

The CO2 impact of concrete construction is due to the sheer volume required to keep up with global needs.

While the cement and concrete industry has long been committed to providing responsible and sustainable high-performance options, there has been a stronger focus on enhancing concrete’s inherent sustainability in recent years.

Cement

Cement producers have made significant strides in operational efficiency and heat recovery, plant modernization, and recycling of industrial byproducts as raw material sources. Over the past 20 years, the Canadian cement industry has reduced the energy consumption required for manufacturing by 20 per cent and GHG emissions by almost 15 per cent.

On top of this, producers are also offering lower carbon products. Portland-limestone cements are specially formulated to provide performance equivalent to traditional Portland varieties, but with a portion of the limestone diverted past the pyro-processing stages and incorporated directly into the product. This avoids around 10 per cent of the CO2 emissions from calcination and combustion.

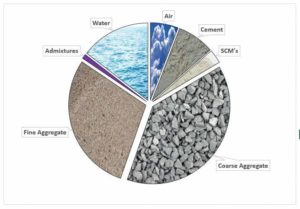

SCMs, such as ground slag, are recycled materials that react with relatively inert byproducts of the hydration reaction (mainly calcium hydroxide) to form compounds that densify the cementitious matrix and enhance later age strength and permeability. SCMs are added to concrete as part of the total cementitious system, and judicious use is desirable not only for the technical advantages, but also environmental benefits. In Canada, it is common to see 25 per cent replacement or more of the cement in concrete with these materials—this corresponds to a comparable reduction in manufacturing energy consumption and GHG emissions, as captured in environmental product declarations (EPDs). Due to these benefits, the industry is trying to increase SCM utilization and investigate new sources of potential materials.

The substitution of traditional fossil fuels with lower carbon alternatives derived from non-recyclable waste, including single-use plastics and waste biomass, has the potential to reduce the industry’s carbon emissions by 20 to 30 per cent across Canada.

Finally, breakthrough carbon capture, utilization, and storage (CCUS) technologies could yield, when scaled, carbon-neutral or even carbon-negative cement and concrete.

Admixtures

Admixtures are small quantities of various chemicals or nanomaterials added to concrete to improve both performance and efficiency. They can provide air entrainment, control setting characteristics, and improve the workability and constructability of fresh concrete. For hardened concrete, they can increase compressive strengths, reduce shrinkage, and help lower permeability. Admixture producers are evolving their technology to enhance concrete’s durability and longevity, while reducing the need for higher quantities of environmentally intensive and costly materials within a particular mix.

Concrete

Concrete producers develop and optimize mix designs to balance the performance requirements of a project while minimizing the environmental impact, resource use, and waste. Several concrete associations in Canada and internationally have developed eco-certification programs for their members. The industry has also been diligent with developing independently verified regional EPDs for various mix designs to communicate transparent and comparable information about the life-cycle impact of products.

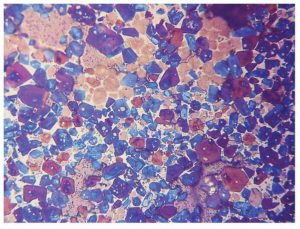

The academic research community is at the leading edge of testing and developing new materials and innovative technologies. This involves working with the standards community to identify requirements for material properties and use, developing appropriate test methods to measure performance, and ensuring the fitness of these products. This includes CCUS-related innovations, such as replacing virgin aggregate with alternatives manufactured from captured carbon as well as various methods for injecting carbon directly into the concrete mix as it sets.

Sustainable concrete

Sustainable concrete meets the performance requirements of the owner, designer, contractors, and the material supplier while minimizing energy consumption, GHG emissions, virgin material extraction, and waste generation. It will also take advantage of local and recycled materials and have high durability and a long service life. Specifications for concrete should not restrict the concrete mixtures being supplied to the jobsite from being more sustainable.

During a project, several parties will be involved in the production and construction process. The custody of the concrete will change hands several times, with each party having the ability to affect the material’s final performance. Problems can arise when conflicts exist between the specification and performance requirements. Fundamentally, these issues arise due to unfamiliarity with the most current and appropriate standards and lack of knowledge regarding local materials, communication, and planning.

The two main options for specifying concrete are prescriptive and performance-based specifications.

With prescriptive specifications, the owner stipulates the material types, sources, quantities, air content, slump, and construction processes, while the contractor plans construction methods around those parameters. The concrete supplier then verifies the concrete complies with those criteria. The specifier assumes responsibility for concrete performance.

Under the performance option, the owner specifies the structural and durability requirements and other performance criteria. The contractor is responsible for procuring concrete and working with the material supplier who will establish mix proportions to meet the plastic and hardened requirements. With performance-based requirements, the concrete supplier assumes responsibility for material as delivered. The contractor is responsible for the concrete as placed. This option provides an advantage as the involved parties are free to use their expertise to innovate and ensure the most efficient, economical, and sustainable product is finally used.