Building Green With Modified Wood: Using acetylated wood to take sustainability to new levels

by Katie Daniel | October 6, 2017 10:59 am

[1]

[1]By Pablo van der Lugt, PhD

Wood’s renewability, ability to sequester carbon (CO2), and natural origins are among the features making it an attractive alternative to synthetic materials. At the same time, new technologies such as cross-laminated timber (CLT) have expanded the number of applications with which wood can be used.

Within the category itself, there have emerged even more sustainable options—wood products that improve even further on existing materials without sacrificing performance or longevity. Among those is acetylated wood, which offers the performance and protection of chemically treated wood products without anything toxic added, making it a sustainable choice for windows, siding, decks, and nearly any other exterior application, in-ground or above.

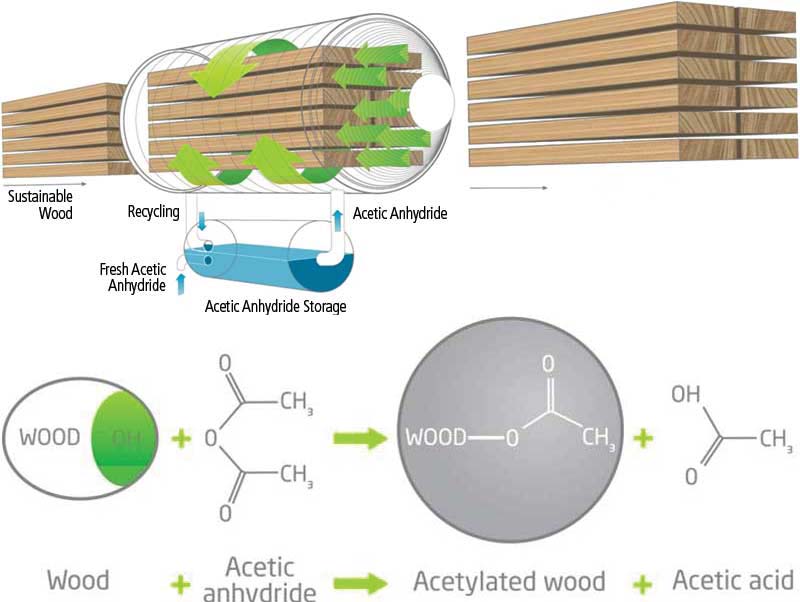

One of several methods for ‘modifying’ wood, acetylation has been studied for more than 90 years, becoming available as a commercial product during the last decade. The acetylation process targets two different elements already contained in the wood—free hydroxyls and acetyl molecules. Free hydroxyl chemical groups readily absorb and release water; they are what causes wood to swell and shrink as temperatures and humidity levels rise and fall. Acetyl groups, also naturally present in the wood, are more stable and do not bond with water.

The acetylation process replaces the free hydroxyls with the acetyl groups. The modified wood, now with a higher level of acetyl molecules, does not respond to moisture like traditional wood does, thereby improving the shrink/swell cycle by 75 per cent or more. The nontoxic modification also makes the wood unrecognizable as a food source, protecting it against rot, decay, and insects. The process changes wood at its molecular level by increasing the natural compounds already found there—nothing is added to the wood that is not naturally present.

The acetylation process alters the wood through to its core, so it can be cut, routed, or otherwise exposed without requiring sealing or other protection. Acetylation is nonreversible, so there is no risk of leaching or loss.

Once the wood is modified, it can be used in a range of exterior applications without treatments, sealants, stains, or paints (though it can be painted or stained if desired for appearance purposes). It is suitable for applications including decking, cladding, windows, doors, and various outdoor furnishings.

[2]

[2]Sustainability across the life cycle

By significantly enhancing the durability and dimensional stability of fast-growing, abundantly available certified wood species—such as radiata pine—calling for acetylated wood can reduce environmental impacts associated with scarce, slow-growing hardwoods or forest products treated with chemicals, as well as nonrenewable carbon-intensive materials such as plastics, steel, and concrete.

When evaluated per life cycle phase, acetylated wood demonstrates the following characteristics from environmental, performance, and human health standpoints.

Production phase

Besides forming a natural ecological habitat, forests are actually an important carbon sink, filtering CO2 out of the air and absorbing it in the biomass of trees. In the case of responsible management, it is actually advised to harvest as much wood as is sustainable for production of durable products such as furniture or construction products, which act as additional carbon stores while providing the forest the opportunity to regenerate and produce new biomass.

However, supplies of certified slow-growing tropical hardwoods suitable for outdoor use are limited, resulting in illegal logging, which in turn leads to the deforestation of tropical rainforests. In tropical regions, deforestation is still continuing, but in temperate regions such as Europe and North America, the net forest area has been increasing steadily for several decades thanks to a focus on sustainable forestry and timberland management.

[3]

[3]Acetylated wood is produced only with abundantly available wood species from certified, sustainably managed forests and plantations, including Forest Stewardship Council (FSC) and other regionally certified woods. It is compliant with the European Union Timber Regulation (EUTR), and therefore responsible production is guaranteed.

Fast-growing softwood species such as radiata pine are primarily used. Considering the increasing pressure on available resources, the use of wood species that produce larger volumes of wood over the same time span for the same area of land offers obvious environmental advantages.

Use phase

Due to its myriad improved properties—such as increased durability, improved thermal insulation, and longer coating life resulting from greater dimensional stability—acetylated wood provides several environmental gains during its use phase.

Due to its light color, acetylated wood has low initial solar reflectance (SR) as tested and reported by Intertek under ASTM C1549-09, Standard Test Method for Determination of Solar Reflectance Near Ambient Temperature Using a Portable Solar Reflectometer. This means it reflects solar radiance and prevents surfaces from warming up too much (i.e. heat island effect). Acetylated wood has an SR value of 0.70, easily meeting the SR requirement of 0.33 that is cited in the Leadership in Energy and Environmental Design (LEED v4) Building Design and Construction (BD+C) program credit, Heat Island Effect.

The material carries a Class 1 durability rating—the highest possible—under EN 350, Durability of Wood and Wood-based Products–Testing and Classification of the Durability to Biological Agents of Wood and Wood-based Materials. Acetylated wood also has extensive quality certifications (including KOMO, RAL, British Board of Agrément [BBA], and Window and Door Manufacturers Association [WDMA]) and a Class C flame spread rating in accordance with ASTM E84, Standard Test Method for Surface Burning Characteristics of Building Materials, which is commonly accepted as an alternative to CAN/ULC-S102, Standard Test Method for Surface Burning Characteristics of Building Materials and Assemblies. The material can be fire treated for further protection, and in some cases is guaranteed to last 50 years above ground and 25 years in direct soil contact. This facilitates a longer life span, which enables lower material consumption over the same period compared to most other materials.

Acetylated wood has carbon sequestration advantages, as it locks in CO2 from the atmosphere for a longer time. In fact, because of low emissions during production combined with the increased lifespan and good recyclability, acetylated window frames may even be CO2 neutral over the full life cycle, per a report translated into real-life application of a window frame by Delft University of Technology. When the radiata pine used to make acetylated wood in the Netherlands is compared to non-acetylated Western red cedar in the United States, a calculation of CO2 emissions shows although the intercontinental transport distance may be high, in many instances, the annual transport emissions of acetylated radiata pine are competitive. Sea transport—an efficient, low-emissions way to move radiata pine—along with its low weight and long lifespan can contribute to this.

Combined with the increased durability, some acetylated wood has a planned service life of 77 to 90 years, depending on exposure conditions. The material’s elevated dimensional stability also requires less frequent coatings maintenance. Additionally, compared to other durable wood species, it offers superior thermal insulation, which yields energy conservation advantages in applications such as window frames.

[4]

[4]End of life

Within the end-of-life phase, acetylated wood completes and continues the cycle. As a nontoxic product, it is fully biodegradable, and thus can be handled in the same manner as untreated wood at the end of its life, fitting perfectly into the Cradle to Cradle design philosophy.

Acetylated wood users can adopt the ‘Ladder of Lansink’ recycling strategy in the end-of-life phase. This model largely follows the guidelines of the Cradle to Cradle philosophy to close biological and technological cycles as much as possible and reuse materials in applications with the same or even higher added value (i.e. up-cycling). The model consists of the following possible waste management scenarios, in which prevention is the most preferred option and dumping the least:

- prevention by avoiding any waste;

- prevention by developing products that do not create harmful waste and are 100 per cent biodegradable;

- useful application through product reuse;

- useful application through material reuse;

- useful application through energy production (i.e. incineration);

- removal through burning; and

- removal through dumping/composting.

Acetylated wood is fully reusable and recyclable. If reuse is impossible, the material can be safely incinerated for bio-energy or composted to close the loop of the carbon cycle. Additionally, byproducts from the production process are reused and recycled to produce acetylated medium-density fibreboard (MDF) or sold to other industries, including the food industry. Waste wood from construction projects also gets a high-quality second life as input material for acetylated MDF, increasing the carbon sink effect.

[5]

[5]Certifications

To both quantify and verify the product’s environmental claims, acetylated wood can acquire several product certifications.

Cradle to Cradle

Certain acetylated wood types have been certified to Cradle to Cradle Gold. Managed by the Cradle to Cradle Products Innovation Institute, this is a multi-attribute product certification[6] that examines products under five categories:

- material health;

- material reutilization;

- renewable energy and carbon management;

- water stewardship; and

- social fairness.

Products are certified at one of five levels—Basic, Bronze, Silver, Gold, or Platinum—in each of the five categories. The lowest rating among those five categories dictates the final certification level.

The Future Build

The Future Build is an Arabian green building materials portal that helps architects, engineers, and contractors confidently select and source environmentally sustainable, third-party-certified products. Its products reflect the standards of sustainability-focused Masdar City, Abu Dhabi. Some acetylated wood types have been rated as excellent or A.

Nordic Ecolabel

Acetylated wood has been officially recognized by Europe’s Nordic nations with the award of the Svanen Ecolabel. The label, renowned for its rigor and transparency, is the internationally recognized ecolabel for Norway, Sweden, Denmark, Iceland, and Finland and was established in 1989 by the Nordic Council of Ministers. It was developed to help consumers and companies select products guaranteed to have met stringent environmental standards.

Google Portico

Google’s Healthy Materials Program, Portico—a building material analysis and decision-making tool—has also recognized acetylated wood with a high-ranking score. Used for Google buildings worldwide and currently available for early access to select architectural firms, with expansion to come, the tool comprises a database of more than 2500 building materials and products evaluated to provide transparency and chemical optimization.

[7]

[7]LEED

Acetylated wood allows architects and designers to achieve several points toward credits under the LEED v4 certification program. These include:

- Sustainable Sites (SS) Credit, Heat Island Reduction, Option 1 (two points);

- Materials and Resources (MR) Credit, Building Life Cycle, Option 4 (three points);

- MR Credit, Building Product Disclosure and Optimization—Environmental Product Declarations, Options 1 and 2 (two points);

- MR Credit, Building Product Disclosure and Optimization—Sourcing Raw Materials, Options 1 and 2 (two points); and

- MR Credit, Building Product Disclosure and Optimization—Material Ingredients, Options 1, 2, and 3 (two points).

Acetylated wood at work

Acetylated wood can be used for a range of exterior applications. Along with offering a wood esthetic without the green of chemicals or the expense and availability concerns of tropical hardwoods, architects are turning to the product for its high performance, long-term durability, minimal maintenance, and low environmental impact.

The City of Kelowna Marina, located on the shore of Lake Okanagan in British Columbia, used acetylated wood siding, trim, and louvres on the retail and services structures and visitor comfort station. The architect, Kasian Architecture, wanted to utilize the natural beauty of wood for the marina buildings’ façades. However, with such a diverse local climate, wood—even tropical hardwoods and common local softwoods—would be susceptible to cracking, twisting, and rot. With this in mind, Kasian sought a wood product able to meet its strict requirements for sustainability, low maintenance, and long lifespan.

Sustainability was also top of mind for the Tashjian Bee Pollinator Center at the University of Minnesota, designed by MSR Design and completed in August 2016. The 699-m2 (7530-sf) centre combines educational programming and public outreach under one roof, with a modern take on the barn-like vernacular of Midwestern farmsteads.

[8]

[8]Photo courtesy Upper Canada Forest Products

The architects chose acetylated wood for the exterior cladding, charring and staining it for a rustic look.

“Using a modernized wood product was a priority from a sustainability aspect,” said Chris Wingate, LEED AP, associate at MSR Design. He noted projects constructed at the university come with a mandatory sustainability overlay, which also drove a necessity for natural materials like the wood cladding.

Durability—along with sustainable sourcing and nontoxic properties—also made acetylated wood an ideal option for the Downtown Yonge parklet on Toronto’s Elm Street. This structure extends the sidewalk into the street with benches, outdoor furniture, landscaping, and other amenities. Designed by architecture students at Ryerson University, the parklet is enjoyed during the summer, then temporarily removed during the winter to allow for snow cleaning.

The Calgary Zoo also chose acetylated wood for the boardwalk in its lemur exhibit, because using this material aligns with its conservation priorities (i.e. deforestation) for the Land of Lemurs. Additional projects specifying acetylated wood throughout Canada include Sulphur Mountain Boardwalk in Banff and Humber College’s 50th Anniversary sign.

Whether installed on a busy street, submerged in a canal, or cladding the sides of a metropolitan retail store, acetylated wood’s properties meet sustainability considerations at many levels. At the same time, it offers the reassurance of long-term performance and esthetics.

Pablo van der Lugt, PhD, is a building engineer, and finished his doctoral research about the environmental impact of bio-based materials at Delft University of Technology in 2008. He then held various ambassador roles in the green building industry. Van der Lugt is currently head of sustainability at Accsys Technologies, and a guest lecturer on bio-based materials at Delft University of Technology. He can be reached via e-mail by writing to pablo.van.der.lugt@accsysplc.com[9].

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/10/acetylated_Kelowna_Marina_Landscape_Case_Study.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/10/Bee-Discovery-Center-SideSilo.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/10/Accoya-Wood-Weber-Shandwick-7.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/10/IMG_1162.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/10/edit1.jpg

- product certification: http://www.c2ccertified.org

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/10/Kelowna_Marina_View.jpg

- [Image]: https://www.constructioncanada.net/wp-content/uploads/2017/10/GRP5828.jpg

- pablo.van.der.lugt@accsysplc.com: mailto:pablo.van.der.lugt@accsysplc.com

Source URL: https://www.constructioncanada.net/building-green-modified-wood-using-acetylated-wood-take-sustainability-new-levels/