Building Durable Structures: From concrete mixes to waterproofing strategies

Durability

Building durable structures, regardless of the material used, has definitely become mainstream knowledge. This is especially true with regard to concrete structures, given that durability directly results in a sustainable structure.

The Portland Cement Association defines durability as:

The ability of concrete to resist weathering action, chemical attack, and abrasion while maintaining its desired engineering properties with minimal loss of mass in an aggressive environment.

Regarding the building of a structure, there are four main steps to create a durable concrete structure:

- mix design—a proper concrete mix-design based on the environment the structure is being built;

- production—ensuring the proper processes and materials are used;

- placing—performing proper compaction to minimize voids and defects; and

- curing—appropriate curing is vital to achieve desirable concrete properties and to minimize the chance of cracking.

Each one of these steps is critical to the process that determines a concrete structure’s durability. For instance, if the placed concrete is not given enough time to cure, it will crack and allow a pathway for water penetration. Further, if the concrete is placed without the proper amount of consolidation, it leads to low strength, and increased permeability.

A durable concrete structure can be created by following the previous steps; however, ignoring these steps will cause a cracked and highly permeable material. As a porous material, concrete can allow water to migrate through, corroding steel reinforcement, bringing in harmful chemicals, or causing other short- or long-term issues requiring serious attention. Thus, in order to build a durable structure, a reliable waterproofing system must be included to help the concrete withstand the infiltration and saturation of water.

Internal and external waterproofing

The predominant cause of concrete deterioration is the infiltration of water. To create a durable structure, one must lower the permeability of the concrete. In order to lower the permeability of the concrete, one must apply a waterproofing solution. This means either waterproofing the concrete with a layer on the outside of the structure or waterproofing from within.

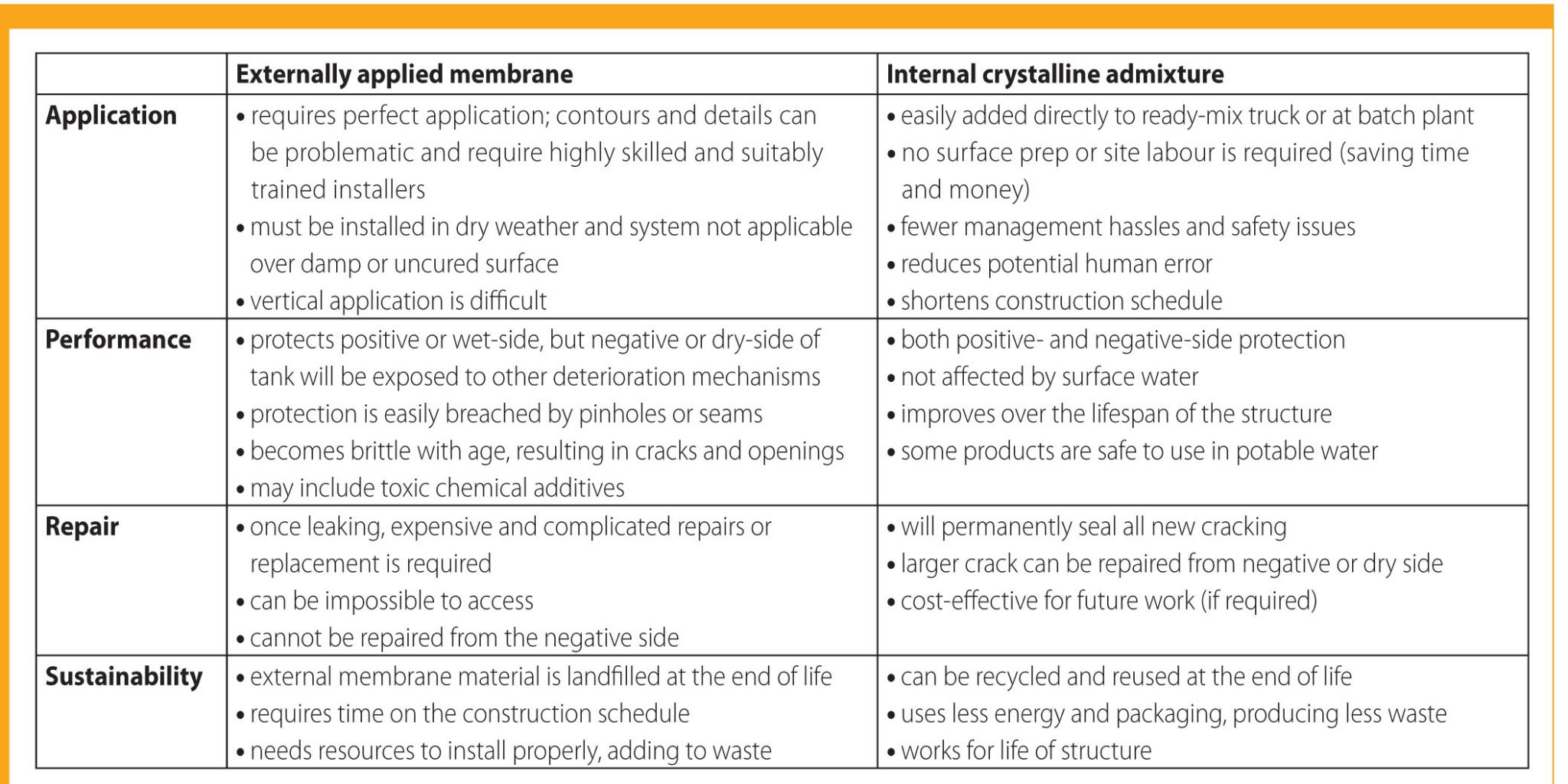

More often than not, the waterproofing measure for concrete projects across Canada is decided between surfaces, or externally applied, membrane and an internal crystalline admixture. The former option continues to be used on more projects because it is still known as the traditional method used for concrete waterproofing. However, crystalline admixtures are becoming more popular as more successful projects are brought into the open. The industry seems to be changing, shifting perspectives from the traditional to the innovative and sustainable.

In the recent past, structures were built on land that provided a lot of space, only went a storey below-grade, and the life expectancy of the structure was shorter. Fast-forward to the present—buildings have sustainability measures they must live up to, including a long service life. Most of the traditional membranes deteriorate over time and have a life much less than service life of today’s structures. Buildings are now built three and four storeys below-grade—a strategy that does not allow access for an external membrane repair. These buildings are also built in high-density areas, meaning repairs are highly complex; in other words, it takes a special skill set for tear-down and then can be quite costly with respect to rebuild. With these new issues comes a call for a change from the traditional.

The table in Figure 1 provides a general comparison, using application, performance, repair, and sustainability as the areas of concern.