Building an acoustic simulation room

Designing a simulation room

As with any acoustically sensitive space, three key design parameters had to be considered: room acoustics, background noise levels, and sound isolation.

Since the room is used to simulate how other spaces will sound, it needed to be as acoustically neutral as possible. To attenuate strong reflections from walls and ceilings, which would harm the accuracy of simulations, acoustically absorptive finishes were used. The walls were fully treated with an acoustically transparent stretch fabric system, backed by 100-mm (4-in.) deep panels of semi-rigid glass fibre insulation to provide acoustical absorption. The ceiling consists of a 25-mm (1-in.) thick suspended mineral wool tile in a T-bar lay-in grid. Additionally, the ceiling cavity behind the tiles was filled with acoustic batt insulation in order to maximize absorption at low frequencies.

While the walls are fully absorptive and parallel wall surfaces are not a concern for flutter echo or other acoustical anomalies, a splayed wall layout was used with an eye on future experimentation with reflective and scattering surfaces in a critical listening environment. It is worth noting that even with full absorptive treatment the room is not entirely free from reflected sound (anechoic) as would be the case in a research environment. However, the magnitude of the acoustic reflections has been reduced sufficiently to avoid interfering with direct sound from the playback system, so convincing building acoustics simulations can be conducted.

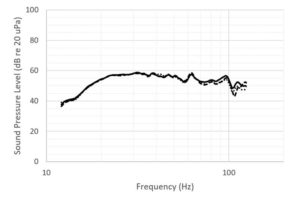

Controlling the background noise level is one of the obstacles when renting a space for simulation purposes. To ensure it was not an issue in the Aercoustics simulation room, the mechanical system was designed to be very quiet (noise criteria [NC]-10) and can also be turned off if needed for threshold of hearing (N1) applications. Additionally, all of the amplifiers and equipment required to operate the room are located in a rack outside of the testing space so there are no cooling fans to interfere with the sound. With 12 powered speakers and four subwoofers in the space, audible hiss and hum was a significant concern. This was addressed by selecting very quiet powered speakers and paying close attention to the design of grounding and wiring feeding the powered speakers and subwoofer amplifiers. The audio signal chain is fully digital up to the speaker feeds that use balanced lines for low noise performance.

To provide an adequate level of sound isolation, the walls were built as isolated double-stud walls with two layers of gypsum on 92-mm (3 5/8-in.) steel studs on both sides with a 25-mm air space in between. Each stud cavity is filled with acoustic batt insulation. To minimize sound transfer, there are no windows in the space and the room was designed with a vestibule comprising a sliding glass door, and a heavy solid wood door with full sound seals. When communication to the outside is required, it is achieved using webcams and talkback microphones, in much the same manner as in a professional recording studio.

Ceilings in the office are 6 m (20 ft) to 9 m (30 ft) in height; due to the extensive height and interferences with mechanical services, the walls were not constructed from the floor to ceiling. Consequently, Aercoustics designed an isolated ceiling system that was constructed from the outer studs and is composed of two layers of gypsum board, insulation, 92-mm studs and two layers of plywood.

Ideally, the floor would have been isolated to create a room-within-a-room construction using either a discontinuous slab-on-grade or a floating floor. The existing floor is continuous slab-on-grade construction and cutting the slab to isolate was not permitted by the landlord. Building a floating slab would have required ramping and loss of significant floor area, which was unacceptable from a layout perspective. With this limitation on design, testing revealed impact noise through the common slab from hard-soled shoes was the only significant concern. This is readily controlled through administrative means.