Better floor performance starts with a solid subfloor system

For the single-layer floor system, 1 1/8 performance category tongue-and-groove floor sheathing should be used with fasteners at 150 mm o.c. or less in the sheathing perimeter and 305 mm (12 in.) o.c. or less in the field.

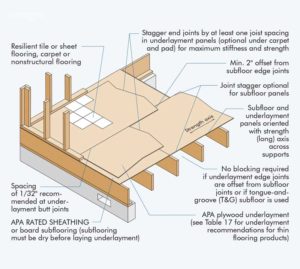

For the double-layer floor system, the base layer of 23/32 performance category tongue-and-groove floor sheathing should be used with fasteners at 150 mm o.c. or less in the sheathing perimeter and 305 mm o.c. or less in the field. The face layer of 19/32 performance category may be square edged, and should be laid over the base layer sheathing (staggered in accordance with APA Engineered Wood Construction Guide [Form E30]) with fasteners at 150 mm o.c. or less in the sheathing perimeter and 305 mm o.c. or less in the field.

Prefabricated wood I-joists of 241 mm (9 1/2 in.) in depth minimum, with a flange size of 28.5 mm (1 1/8 in.) in thickness by 45 mm (1 3/4 in.) in width minimum, at a maximum joist spacing of 610 mm (24 in.) o.c.

A 89-mm (3 1/2 in.) thick R-13 fibreglass batt insulation should be installed in the joist cavities with the exception of the assembly covered by cushioned vinyl, in which a layer of 76-mm (3-in.) thick mineral wool 45 kg/m3 (2.8 pcf) insulation should be installed instead.

RC-1 resilient channels 0.43-mm (17-mils) thick should be installed perpendicular to the bottom of the I-joist flanges at 406 mm o.c. with 31.5 mm (1 1/4 in.) Type W drywall screws.

Two layers of 15.5 mm (5/8 in.) Type X gypsum boards complying with ASTM C1396, Standard Specification for Gypsum Board, should be attached perpendicular to the resilient channels with 25 mm and 40.5 mm (1 5/8 in.) Type S drywall screws at 305 mm (12 in.) o.c. for the base and face layers of gypsum boards, respectively.

Properly prepping concrete subfloors

APA-rated WSPs can also be used over concrete slab floors in both commercial and residential applications. Three methods of application are usually considered in this scenario:

- structural panels installed over sleepers on top

of concrete; - over rigid foam on top of concrete; or

- directly over concrete itself.

The success of all three application methods depends heavily on the establishment of a proper vapour retarder. For new construction where a wood floor over a concrete slab is contemplated, a 6-mil PE vapour retarder should be installed underneath the concrete slab. For remodeling work it is best to install a vapour retarder over the existing slab. It is important to remember wood products installed between the vapour retarder and the slab should be pressure-preservative-treated.

Installing WSPs over sleepers

Installing WSPs over sleepers is the most straightforward and cost-effective method of application over a concrete slab. In this method, APA-rated subfloor underlayment tongue-and-groove panels, Exposure-1, are placed across 50 x 100-mm (2 x 4-in.) sleepers (installed flatwise), which can be spaced to match the span rating of the panels. There are several advantages to this system.

The sleepers can be attached to the concrete floor with construction adhesive and/or fasteners, thus providing a nail base for the combination subfloor underlayment. This method minimizes the reduction in headroom to a little over 50 mm, and allows the combination subfloor underlayment to be applied in a conventional manner using deformed shank nails and subfloor adhesive. It is advisable to use a construction adhesive meeting ASTM D3498.

The vapour retarder, when used above the slab, can be placed over preservative-treated sleepers or under untreated sleepers. When the vapour retarder is applied over the concrete slab floor, but under the sleepers, the sleepers must be mechanically fastened to the slab.